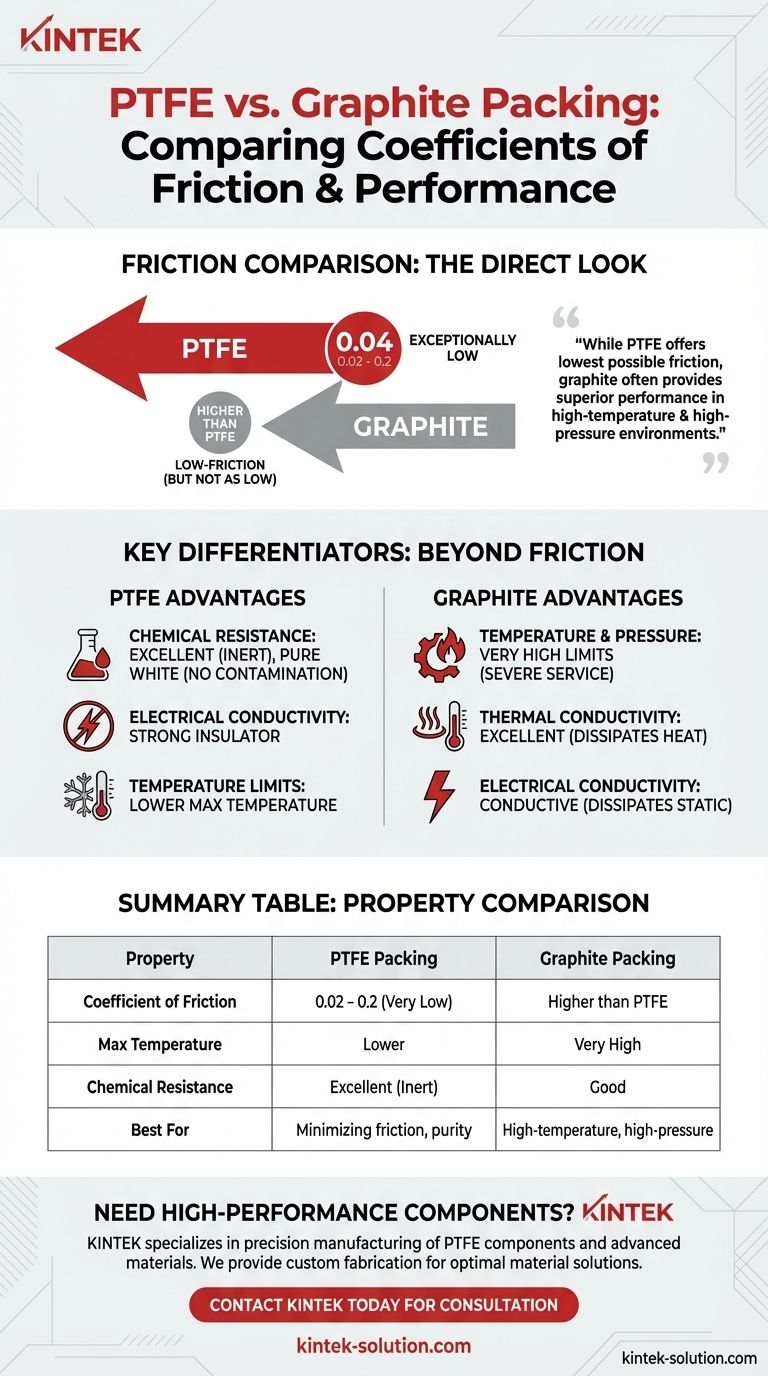

In a direct comparison, PTFE (polytetrafluoroethylene) packing has a significantly lower coefficient of friction than graphite packing. PTFE's friction coefficient is exceptionally low, often cited around 0.04, which is recognized as the lowest of any solid engineering material. While graphite is also a low-friction material, PTFE is the clear benchmark when minimizing friction is the absolute priority.

The choice between these materials is rarely based on friction alone. While PTFE offers the lowest possible friction, graphite often provides superior performance in high-temperature and high-pressure environments, making the selection a critical balance of operational demands.

Unpacking the Friction Difference

Understanding the coefficient of friction is central to selecting the right packing material. This single property directly impacts equipment longevity, energy consumption, and operational reliability.

The Unmatched Performance of PTFE

PTFE is a synthetic polymer renowned for its slick, non-stick surface. Its coefficient of friction is remarkably low, typically ranging from 0.02 to 0.2, with a common dynamic value of 0.04.

This exceptionally low value means less force is required to move parts against the packing. The result is less heat generation, reduced wear on shafts and stems, and lower energy consumption.

Graphite's Low-Friction Profile

Graphite, a natural form of pure carbon, is also a high-performance packing material with a low coefficient of friction. It offers excellent self-lubricating properties.

While its friction coefficient is not as low as PTFE's, it is still a significant improvement over many other materials, making it a reliable choice for reducing wear and operational force in many applications.

It's More Than Just Friction: Key Differentiators

If PTFE has a lower friction coefficient, the logical question is why anyone would choose graphite. The answer lies in other critical performance characteristics where graphite often has an advantage.

Chemical Resistance and Purity

PTFE is almost completely chemically inert, resistant to nearly all acids, gases, and corrosive substances, with the rare exception of molten alkali metals. Its white color also ensures it does not transfer color or contaminate media, a vital feature in industries like food and pharmaceuticals.

Electrical and Thermal Conductivity

PTFE is a strong electrical insulator. This property helps prevent galvanic corrosion between dissimilar metals in a valve or pump assembly.

Graphite, being carbon, is electrically conductive. This can be an advantage for dissipating static electricity but can also contribute to galvanic corrosion if not managed properly. More importantly, graphite has excellent thermal conductivity, allowing it to dissipate heat away from the shaft, which is crucial in high-temperature service.

Temperature and Pressure Limits

This is often the most critical trade-off. While PTFE performs exceptionally well within its operational window, it has clear temperature limits. Graphite packing, by contrast, can handle significantly higher temperatures and pressures, making it the default choice for severe service applications in power plants, refineries, and chemical processing.

Understanding the Trade-offs

Choosing between PTFE and graphite requires a clear-eyed assessment of the application's entire operational profile. Focusing on one metric, even one as important as friction, can lead to premature failure.

The PTFE Advantage: Friction and Purity

The primary reasons to select PTFE are its unparalleled low friction and its chemical purity. It excels in applications where minimizing shaft wear, reducing actuation force, and preventing product contamination are the highest priorities.

The Graphite Advantage: Extreme Conditions

The primary reason to select graphite is its robustness in extreme environments. It maintains its integrity and sealing capability at temperatures and pressures that would cause PTFE to degrade and fail. Its ability to dissipate heat is a major advantage in high-speed rotating equipment.

Making the Right Choice for Your Application

Your final decision must align with the most demanding aspect of your specific service conditions.

- If your primary focus is minimizing friction and energy use: PTFE packing is the superior choice due to its exceptionally low coefficient of friction.

- If your application involves high temperatures or high pressures: Graphite packing offers the thermal stability and resilience required for reliable, long-term sealing.

- If you require extreme chemical inertness and electrical insulation: PTFE provides a more robust defense against a wider range of corrosive media and galvanic action.

- If you need to manage heat in a high-speed application: Graphite's ability to conduct heat away from the shaft is a critical advantage for preventing overheating.

Ultimately, selecting the correct packing is about matching the material's complete profile to your application's unique challenges.

Summary Table:

| Property | PTFE Packing | Graphite Packing |

|---|---|---|

| Coefficient of Friction | 0.02 - 0.2 (Very Low) | Higher than PTFE |

| Max Temperature | Lower | Very High |

| Chemical Resistance | Excellent (Inert) | Good |

| Best For | Minimizing friction, purity | High-temperature, high-pressure |

Need High-Performance PTFE or Graphite Components?

Selecting the right sealing or packing material is critical for your equipment's efficiency and longevity. KINTEK specializes in the precision manufacturing of PTFE components (seals, liners, labware) and other advanced materials for the semiconductor, medical, laboratory, and industrial sectors.

We provide custom fabrication from prototypes to high-volume orders, ensuring you get the optimal material solution for your specific temperature, pressure, and friction requirements.

Let our experts help you solve your toughest application challenges. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications