In short, Teflon sheets protect garments by acting as a crucial barrier between the hot upper platen of a heat press and your project. This non-stick, heat-resistant shield prevents direct contact, which is the primary cause of scorching, melting, and unwanted residue transfer during the application of heat transfer vinyl (HTV) or sublimation ink.

The core function of a Teflon sheet is not just to prevent burns, but to ensure a clean, controlled, and even transfer of heat. It safeguards the garment, the heat transfer material, and the press itself, making it an indispensable tool for achieving professional-quality results.

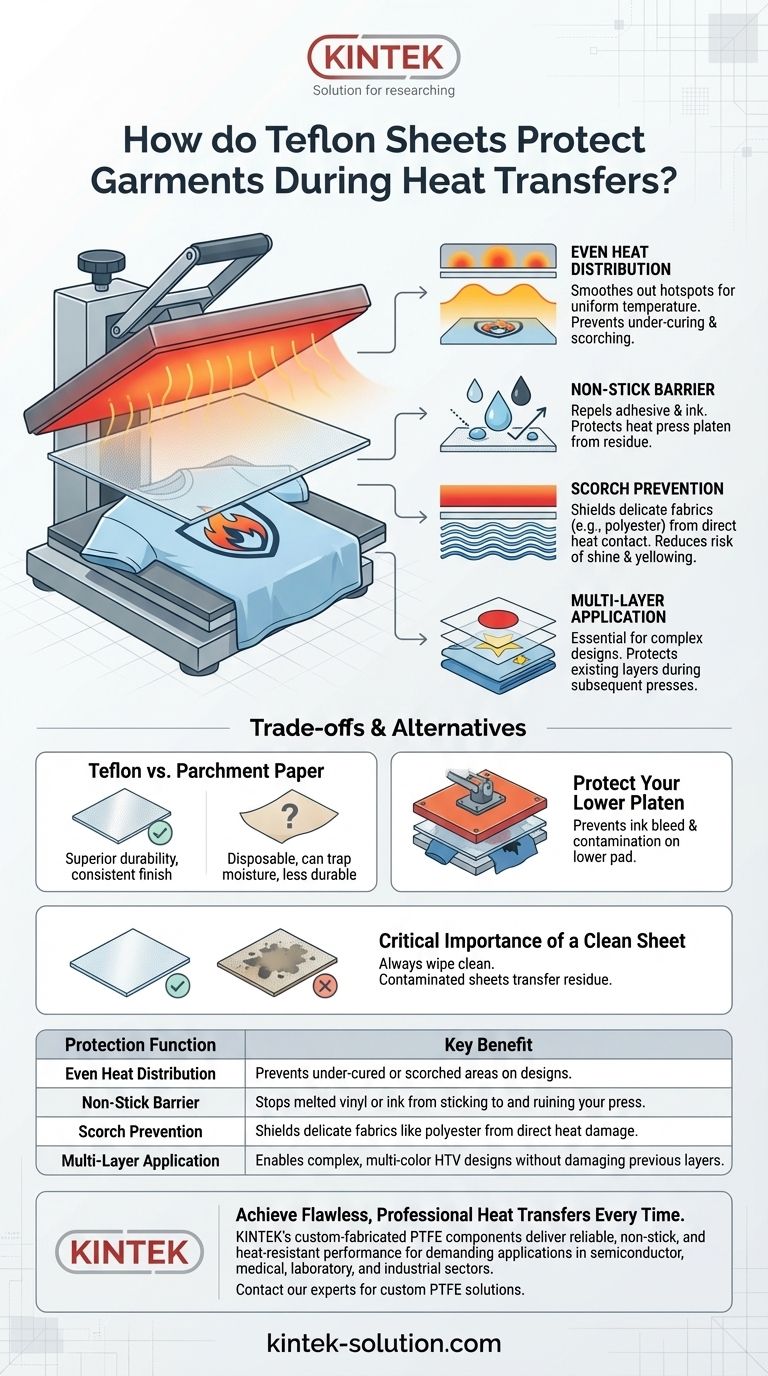

The Core Mechanisms of Protection

A Teflon sheet may seem like a simple accessory, but it performs several critical functions simultaneously. Understanding these mechanics is key to avoiding common heat pressing failures.

Distributing Heat Evenly

A heat press platen, despite its design, can have microscopic hot spots. The Teflon sheet acts as a buffer, smoothing out these minor temperature variations across the surface of your design.

This even distribution ensures every part of the transfer receives the correct temperature, preventing parts of the design from being under-cured while others are scorched.

Creating a Non-Stick Barrier

This is the most well-known function. Teflon's non-stick properties prevent any melted vinyl adhesive or excess sublimation ink from sticking to the hot upper platen of your press.

Without this barrier, residue would bake onto your platen, which could then be transferred to and ruin subsequent projects. It protects your investment in your equipment.

Preventing Direct Contact Scorching

Delicate fabrics, especially synthetics like polyester or blends, are prone to yellowing or developing a sheen (scorching) when exposed to high, direct heat.

The Teflon sheet provides just enough of a thermal buffer to shield the fabric fibers from direct contact with the metal platen, significantly reducing the risk of scorch marks even at proper time and temperature settings.

Enabling Advanced Techniques

For projects involving multiple colors or layers of HTV, a Teflon sheet is essential. Each layer must be pressed individually.

The sheet protects the previously applied vinyl layers from re-melting or getting a texture imprint from the platen while you apply the next layer. This allows for complex, multi-color designs without damaging your work.

Understanding the Trade-offs and Alternatives

While a Teflon sheet is the industry standard, it's important to understand its context and common points of confusion.

Teflon Sheet vs. Parchment Paper

Parchment paper is a common, disposable alternative. It provides a non-stick surface and can work in a pinch.

However, Teflon sheets are superior for consistent, professional work. They are far more durable for hundreds of presses, provide a smoother finish, and do not risk trapping moisture like paper can, which can interfere with sublimation.

Protecting Your Lower Platen

Protection isn't just for the top. It's good practice to place a Teflon sheet or protective paper inside the garment or on the lower platen.

This prevents any inks or dyes from the "back" side of a garment (like a red shirt) from bleeding onto your lower platen's pad and then transferring to the next (perhaps white) shirt you press.

The Critical Importance of a Clean Sheet

A Teflon sheet is only as good as its condition. Any stray bits of vinyl, adhesive, or ink residue on your sheet will be transferred to your next project.

Always wipe your sheet clean after use, especially between different types of projects. A contaminated sheet will cause problems, not prevent them.

Making the Right Choice for Your Goal

Using a cover sheet is non-negotiable for quality work. Your choice depends on your primary application.

- If your primary focus is Heat Transfer Vinyl (HTV): A Teflon sheet is essential for protecting vinyl from direct heat, especially when layering multiple colors.

- If your primary focus is Sublimation: Use a fresh sheet of parchment or butcher paper for every press to prevent ink "ghosting" and blow-by from ever contaminating your Teflon sheet or platen.

- If your primary focus is working with delicate fabrics: A Teflon sheet provides the best protection against scorching and yellowing on polyesters and blends.

Mastering the use of this simple protective barrier is a fundamental step toward eliminating errors and producing flawless results every time.

Summary Table:

| Protection Function | Key Benefit |

|---|---|

| Even Heat Distribution | Prevents under-cured or scorched areas on designs. |

| Non-Stick Barrier | Stops melted vinyl or ink from sticking to and ruining your press. |

| Scorch Prevention | Shields delicate fabrics like polyester from direct heat damage. |

| Multi-Layer Application | Enables complex, multi-color HTV designs without damaging previous layers. |

Achieve Flawless, Professional Heat Transfers Every Time

Just as a high-quality Teflon sheet is essential for protecting your garments, the precision and durability of your components are critical to your success. For businesses in the semiconductor, medical, laboratory, and industrial sectors, KINTEK's custom-fabricated PTFE components—including seals, liners, and labware—deliver the same level of reliable, non-stick, and heat-resistant performance required for demanding applications.

We specialize in precision production, from prototypes to high-volume orders, ensuring your equipment operates flawlessly. Let's discuss how our custom PTFE solutions can enhance your product's performance and reliability.

Contact our experts today to get a quote for your custom PTFE needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key product features of Teflon lip seals? Engineered for Extreme Performance

- What are the benefits of using PTFE lined check valves in water pump systems? Boost Reliability & Cut Costs

- How can the mechanical properties of PTFE be improved? Enhance Strength & Durability with Fillers

- What are the characteristics of virgin grade PTFE (Teflon) gaskets? Unmatched Purity & Chemical Resistance

- What are the minimum and maximum sizes for machining PTFE parts? Design for Success with No Universal Limits

- What are the advantages of PTFE's chemical resistance in sealing applications? Ensure Unmatched Reliability in Harsh Environments

- What are the automotive applications of Teflon sheets? Enhance Efficiency, Reliability & Durability

- What are the basic materials used in slide bearings? Explore PTFE, Composites & Multi-Layer Designs