In short, PTFE seals perform exceptionally well in both dynamic and thermal cycling applications due to their unique two-part construction. The combination of a durable, low-friction PTFE jacket and an internal spring energizer allows them to maintain a consistent sealing force despite wear, high speeds, and extreme temperature fluctuations.

The core reason for their success is the synergy between the materials: the chemically inert and temperature-stable PTFE jacket provides the sealing surface, while the internal metal spring constantly compensates for environmental changes and material wear, a function where traditional elastomers often fail.

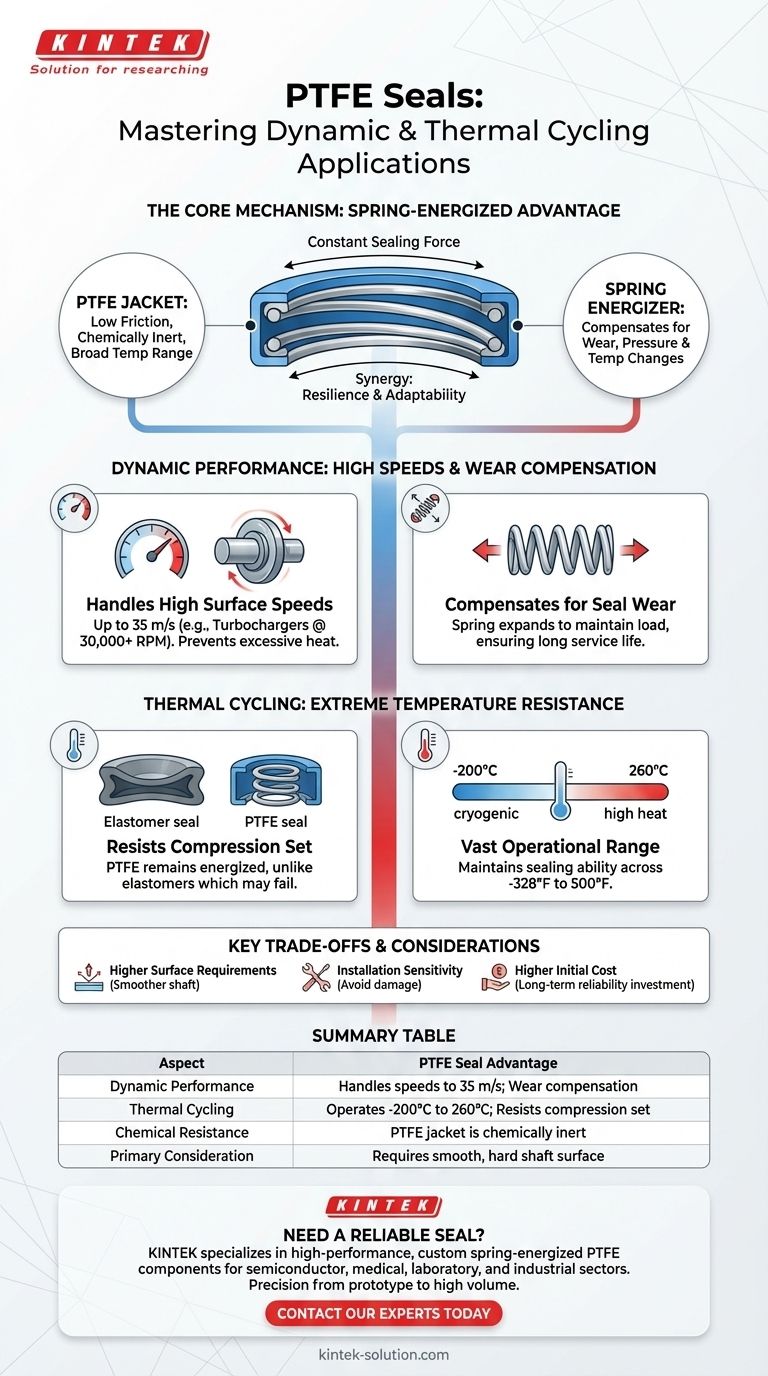

The Core Mechanism: The Spring-Energized Advantage

The superior performance of PTFE seals in demanding conditions stems from how their components work together. It's a system designed for resilience where standard seals fall short.

The Role of the PTFE Jacket

Polytetrafluoroethylene (PTFE) is a polymer known for its remarkable properties. Its extremely low coefficient of friction minimizes heat generation in high-speed applications.

Furthermore, its chemical inertness and wide operational temperature range mean the sealing material itself does not degrade when exposed to harsh chemicals, cryogenic cold, or high heat.

The Function of the Spring Energizer

Unlike a standard O-ring that relies on its own material "squeeze" to seal, a spring-energized seal uses a metal spring to generate its sealing force.

This spring acts as a constant source of energy, pushing the PTFE lips against the sealing surfaces. This is the key to its adaptability.

Synergy in Action

The spring continuously applies a precise load, ensuring the PTFE jacket maintains contact with the shaft. This remains true despite changes in pressure, temperature, or minor shaft misalignment, creating a highly reliable and persistent seal.

Performance in High-Demand Dynamic Applications

Dynamic applications involve constant movement, which introduces challenges like friction, heat, and wear. Spring-energized PTFE seals are engineered specifically to overcome these issues.

Handling High Surface Speeds

PTFE seals can manage shaft surface speeds up to 35 m/s, significantly faster than many elastomeric alternatives.

Their low-friction nature prevents the excessive heat generation that can lead to premature seal failure in high-speed rotational equipment like turbochargers, which can see speeds of over 30,000 RPM.

Compensating for Inevitable Seal Wear

In any dynamic seal, the sealing lip will wear down over time. In a PTFE seal, the internal spring simply expands to follow the worn surface.

This automatic adjustment ensures the seal maintains its load and continues to function effectively over a long service life, preventing leaks as the component ages.

Excelling Under Extreme Thermal Cycling

Thermal cycling—the repeated fluctuation between hot and cold—is a common point of failure for many sealing materials. This is where spring-energized PTFE seals demonstrate their most significant advantage over elastomers.

Resisting Compression Set

Elastomers tend to take a compression set when held in a deformed shape, especially at high temperatures. When they cool, they may not return to their original shape, creating a leak path.

PTFE, being a more rigid thermoplastic, does not suffer from this issue. The spring energizer ensures the sealing lips remain energized and in position, regardless of temperature history.

A Vast Operational Temperature Range

PTFE seals maintain their properties and sealing ability across an exceptionally broad temperature spectrum, often cited from -200°C to 260°C (-328°F to 500°F).

This makes them one of the few viable options for applications that cycle between cryogenic conditions and high-temperature operation. The spring's performance is not compromised by these thermal swings.

Understanding the Trade-offs and Considerations

While highly effective, PTFE seals are not a universal solution. Their design brings specific trade-offs that are critical to understand for successful implementation.

Higher Sealing Surface Requirements

Because PTFE is a harder material than rubber, it is less forgiving of imperfections. For optimal performance and seal life, PTFE seals typically require a harder and smoother shaft surface finish than what might be acceptable for a standard elastomeric seal.

Installation Sensitivity

The relative rigidity of the PTFE jacket can make installation more challenging than with a highly flexible elastomer. Care must be taken to avoid scratching the sealing lip or damaging the jacket during assembly.

Higher Initial Cost

The multi-component design and advanced materials mean that spring-energized PTFE seals generally have a higher upfront cost than simple elastomeric O-rings or lip seals. This cost, however, is often justified by longer service life and greater reliability in demanding applications.

Making the Right Choice for Your Application

Selecting the correct seal requires matching the technology to the operational demands. A clear understanding of your primary challenge is the key to making an informed decision.

- If your primary focus is high-speed rotation or frequent movement: The low-friction and wear-compensating nature of a spring-energized PTFE seal makes it a superior choice for long-term reliability.

- If your primary focus is applications with extreme temperature swings: The PTFE seal's resistance to compression set and its stable material properties provide unmatched performance where elastomers would quickly fail.

- If your primary focus is a cost-sensitive, static application with stable temperatures: A standard elastomeric seal is likely the more economical and perfectly suitable solution.

Ultimately, choosing a spring-energized PTFE seal is an investment in reliability for applications where environmental conditions exceed the limits of conventional materials.

Summary Table:

| Key Performance Aspect | PTFE Seal Advantage |

|---|---|

| Dynamic Performance | Handles surface speeds up to 35 m/s; spring compensates for wear. |

| Thermal Cycling | Operates from -200°C to 260°C; resists compression set. |

| Chemical Resistance | PTFE jacket is chemically inert against harsh media. |

| Primary Consideration | Requires a smooth, hard shaft surface for optimal performance. |

Need a reliable seal for extreme conditions?

KINTEK specializes in manufacturing high-performance PTFE components, including custom spring-energized seals for the semiconductor, medical, laboratory, and industrial sectors. We provide precision production from prototypes to high-volume orders to ensure your equipment operates flawlessly under pressure, heat, and motion.

Contact our experts today to discuss your specific application requirements and get a custom solution that delivers long-term reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What role do PTFE gaskets play in the medical and pharmaceutical industries? Ensuring Purity and Safety in Critical Applications

- What benefits do fillers provide for PTFE lip seals? Enhance Wear, Pressure, and Thermal Performance

- What are the future trends for PTFE sheets in industrial innovation? From Commodity to Custom-Engineered Solutions

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- How does a PTFE Lined Butterfly Valve operate? A Guide to Corrosive Flow Control

- What are the main ingredients used to make PTFE? The Chemistry Behind a High-Performance Polymer

- What is the heat resistance capability of PTFE seals? Withstand -200°C to 260°C for Unmatched Reliability

- What industries are PTFE gaskets particularly suitable for? Ideal for Chemical, Pharma, and Food Processing