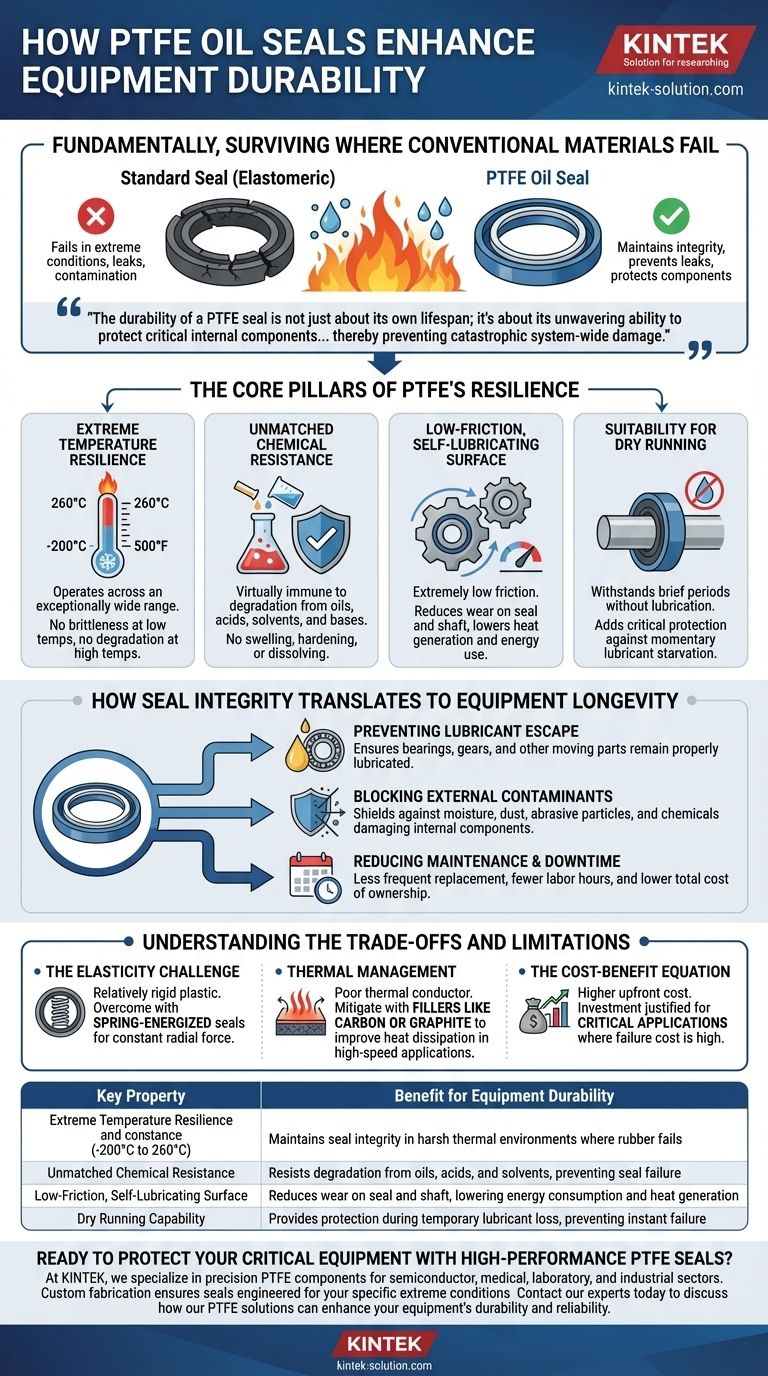

Fundamentally, PTFE oil seals enhance equipment durability by surviving where conventional materials fail. Their unique molecular structure provides a powerful combination of extreme temperature stability, chemical inertness, and low-friction performance. This allows the seal to maintain its integrity in harsh operating conditions, reliably preventing leaks and contamination that would otherwise lead to premature equipment failure.

The durability of a PTFE seal is not just about its own lifespan; it's about its unwavering ability to protect critical internal components from lubricant loss and external contaminants in extreme environments, thereby preventing catastrophic system-wide damage.

The Core Pillars of PTFE's Resilience

The remarkable durability of Polytetrafluoroethylene (PTFE) stems from a few key material properties that set it apart from traditional elastomeric seals.

Extreme Temperature Resilience

PTFE seals operate effectively across an exceptionally wide temperature range, typically from -200°C to 260°C (-328°F to 500°F).

Unlike rubber seals that can become brittle at low temperatures or degrade rapidly at high temperatures, PTFE maintains its structural integrity and sealing capability.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert polymers known. It is virtually immune to degradation from aggressive fluids, including oils, acids, solvents, and bases.

This prevents the seal itself from swelling, hardening, or dissolving, which is a common failure mode for standard seals exposed to harsh chemicals.

Low-Friction, Self-Lubricating Surface

The material has an extremely low coefficient of friction, one of the lowest of any solid material. This means it creates less drag and generates less heat on a rotating shaft.

This reduces wear on both the seal lip and the shaft itself, extending the service life of both components and lowering the energy required to run the equipment.

Suitability for Dry Running

Because of its self-lubricating nature, PTFE seals can withstand brief periods of dry running—operating without lubrication—that would instantly destroy a conventional rubber seal. This adds a critical layer of protection against momentary lubricant starvation.

How Seal Integrity Translates to Equipment Longevity

A seal's primary job is to protect the machinery behind it. The durability of a PTFE seal directly translates into a longer, more reliable life for the entire piece of equipment.

Preventing Lubricant Escape

The most critical function of a seal is to keep lubricants inside the system. By resisting degradation, a PTFE seal provides a consistent, long-term barrier that ensures bearings, gears, and other moving parts remain properly lubricated.

Blocking External Contaminants

A durable seal is also a superior shield. PTFE's non-stick surface and stable form prevent moisture, dust, abrasive particles, and chemicals from entering the system and damaging sensitive internal components.

Reducing Maintenance and Downtime

Because PTFE seals last significantly longer in demanding applications, they reduce the frequency of replacement. This leads to less scheduled downtime, fewer labor hours, and a lower total cost of ownership over the equipment's lifespan.

Understanding the Trade-offs and Limitations

While powerful, PTFE is not a universal solution. Acknowledging its trade-offs is key to using it effectively.

The Elasticity Challenge

PTFE is a relatively rigid plastic, not a flexible elastomer like rubber. It has poor "memory" and doesn't spring back into shape on its own.

To overcome this, high-performance PTFE seals are almost always spring-energized. A metallic spring inside the seal jacket provides the constant radial force needed to maintain a tight seal against the shaft.

Thermal Management Considerations

While it resists high temperatures, PTFE is a poor thermal conductor, meaning it can trap heat at the sealing point.

For very high-speed applications, this can be a concern. To mitigate this, manufacturers often add fillers like carbon, graphite, or even copper to the PTFE blend to improve thermal conductivity and dissipate heat.

The Cost-Benefit Equation

PTFE seals are more expensive upfront than their standard rubber counterparts. Their use is not justified for simple, non-demanding applications.

The higher cost is an investment that pays dividends in critical applications where the cost of failure—in terms of downtime, safety, or damage to expensive equipment—is unacceptably high.

Making the Right Choice for Your Application

Selecting the right seal requires matching the material to the operational demands.

- If your primary focus is extreme temperature environments: PTFE is the superior choice for its unparalleled operating window where elastomers would fail.

- If your primary focus is chemical compatibility: Specify PTFE when dealing with aggressive solvents, acids, or fluids that would quickly degrade standard seals.

- If your primary focus is reducing friction in high-speed systems: PTFE's self-lubricating properties minimize wear and energy consumption, making it ideal for high-RPM shafts.

- If your primary focus is minimizing cost for a standard application: A traditional elastomeric seal is likely more cost-effective if operating conditions are moderate and not chemically aggressive.

By understanding these characteristics, you can deploy PTFE seals not just as components, but as a strategic investment in long-term equipment reliability.

Summary Table:

| Key Property | Benefit for Equipment Durability |

|---|---|

| Extreme Temperature Resilience (-200°C to 260°C) | Maintains seal integrity in harsh thermal environments where rubber fails |

| Unmatched Chemical Resistance | Resists degradation from oils, acids, and solvents, preventing seal failure |

| Low-Friction, Self-Lubricating Surface | Reduces wear on seal and shaft, lowering energy consumption and heat generation |

| Dry Running Capability | Provides protection during temporary lubricant loss, preventing instant failure |

Ready to protect your critical equipment with high-performance PTFE seals?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services, from prototypes to high-volume orders, ensure you get a seal engineered to withstand your specific extreme conditions, reducing downtime and total cost of ownership.

Contact our experts today to discuss how our PTFE solutions can enhance your equipment's durability and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- How do Teflon parts benefit the electronics industry? Achieve Superior Performance in Harsh Environments

- What role do PTFE expansion joints play in power generation facilities? Ensure Reliability and Cut Costs

- What are the physical properties of PTFE balls? A Guide to Extreme Chemical & Thermal Performance

- Is carbon filler more or less abrasive than glass filler in PTFE? Protect Your Mating Surfaces

- What are the limitations of virgin PTFE in high-temperature applications? Avoid Creep and Sealing Failures

- What industries commonly use PTFE expansion joints and why? Solve Critical Pipeline Challenges with PTFE

- How do ceramic-filled PTFE laminates differ from standard PTFE laminates? Superior Signal Integrity for RF/Microwave

- What are the qualities of PTFE seals? The Key to Reliability in Extreme Conditions