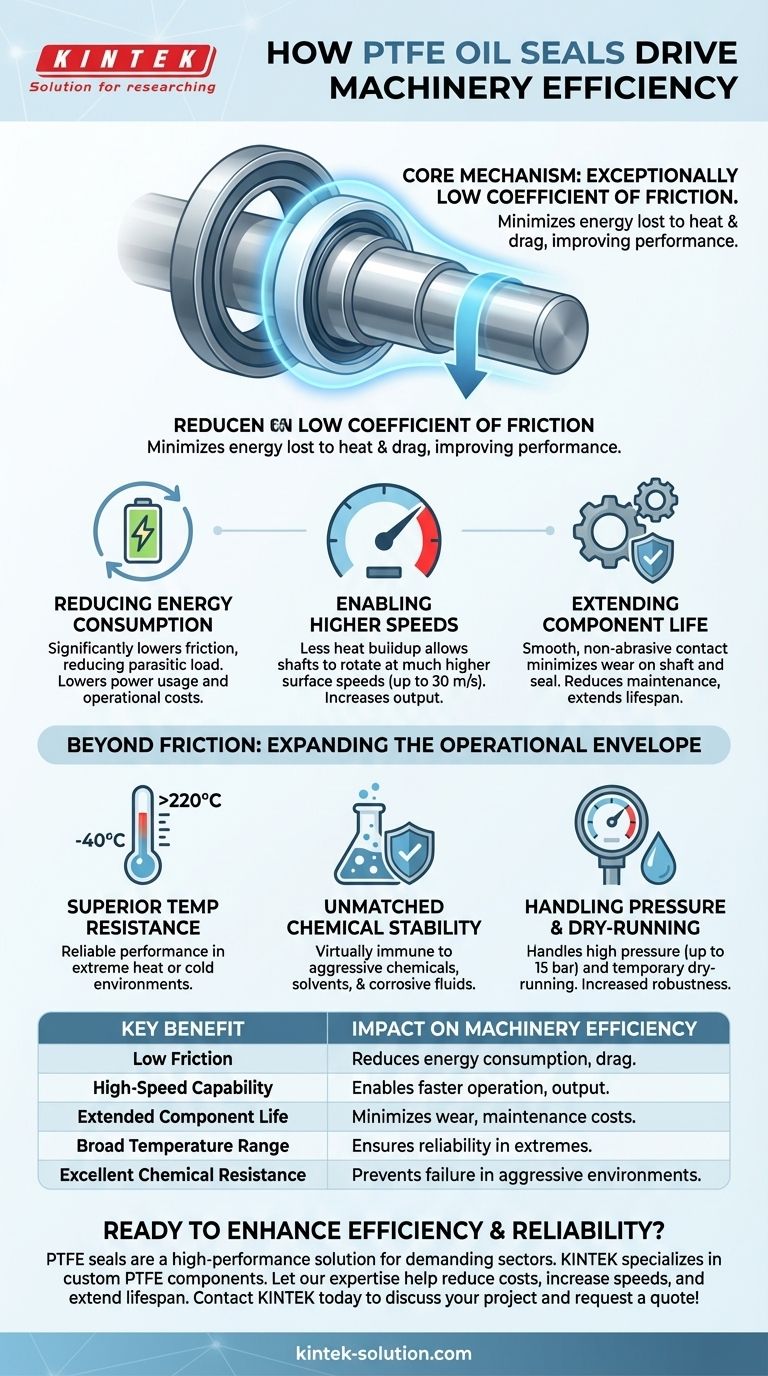

At their core, PTFE oil seals improve machinery efficiency primarily through their exceptionally low coefficient of friction. This characteristic minimizes the energy lost to heat and drag between the seal and the rotating shaft, allowing the machine to perform its intended work with less wasted power.

While the immediate benefit is reduced energy consumption, the true value of PTFE seals lies in how they expand a machine's entire performance envelope—enabling higher speeds, wider temperature ranges, and longer service life, which collectively redefine operational efficiency.

The Core Mechanism: Minimizing Frictional Loss

The fundamental advantage of Polytetrafluoroethylene (PTFE) is its incredibly slick surface. This single property creates a ripple effect of efficiency gains throughout a mechanical system.

Reducing Energy Consumption

Friction is a direct source of energy loss. A seal rubbing against a spinning shaft generates drag, forcing the motor or engine to work harder just to overcome this resistance.

By significantly lowering this friction, PTFE seals reduce the parasitic load on the system. This directly translates to lower energy consumption and tangible cost savings over the machine's life.

Enabling Higher Rotational Speeds

Excessive friction generates heat. In traditional rubber seals, this heat buildup can cause the seal material to degrade, limiting the maximum speed of the shaft.

PTFE's low-friction nature produces far less heat, allowing shafts to operate at much higher surface speeds (up to 30 m/s). This enables machinery to run faster and increase its output, a critical form of process efficiency.

Extending Component Life

Friction causes wear on both the seal and the shaft it contacts. Abrasive wear on a shaft is costly, often requiring expensive disassembly and repair or replacement.

The smooth, non-abrasive contact of a PTFE seal minimizes wear on the shaft surface. This extends the service life of not just the seal but also the expensive hardware it protects, reducing long-term maintenance costs.

Beyond Friction: Expanding the Operational Envelope

While low friction is the primary driver, PTFE's material properties unlock performance capabilities that are simply not possible with conventional seals, further contributing to overall system efficiency.

Superior Temperature Resistance

PTFE seals operate reliably across an extremely broad temperature range, typically from -40°C to over 220°C.

This allows machinery to function consistently in environments with extreme heat or cold where traditional rubber seals would become brittle or melt, preventing costly failures and downtime.

Unmatched Chemical Stability

PTFE is one of the most chemically inert materials used in industry. It is virtually immune to aggressive chemicals, solvents, and corrosive fluids.

This ensures a reliable seal in demanding applications like chemical processing or manufacturing, where seal failure could lead to leaks, equipment damage, and unsafe conditions.

Handling Pressure and Dry-Running

Modern PTFE seal designs can handle significant pressure (up to 15 bar) and are more tolerant of poor lubrication or even temporary dry-running conditions. This adds a layer of robustness, making the machine more resilient to non-ideal operating states and preventing catastrophic failure.

Understanding the Trade-offs

To make an informed decision, it's critical to see PTFE seals not as a universal upgrade but as a high-performance solution for specific challenges.

The Cost Factor

PTFE seals have a higher upfront cost compared to conventional elastomeric (rubber) oil seals. They are a premium component engineered for demanding applications.

When Conventional Seals Are Sufficient

For many standard applications with moderate speeds, temperatures, and non-aggressive fluids, a traditional rubber seal performs perfectly well and is the more cost-effective choice.

The decision to use PTFE is justified when the operational demands exceed the limits of conventional materials, making the investment in reliability and performance a sound one.

Making the Right Choice for Your Application

Selecting the correct seal requires aligning the material's strengths with your primary operational goal.

- If your primary focus is maximizing energy efficiency: PTFE's low-friction nature directly reduces power consumption and long-term operational costs.

- If your primary focus is increasing machine performance: PTFE's ability to handle high speeds and temperatures allows you to push equipment to its design limits, boosting output.

- If your primary focus is reliability and minimizing downtime: PTFE's superior durability and resistance to harsh conditions deliver longer service intervals and fewer unexpected failures.

Ultimately, choosing the right seal is a strategic decision that balances upfront cost against the long-term demands for performance and reliability.

Summary Table:

| Key Benefit | Impact on Machinery Efficiency |

|---|---|

| Low Friction | Reduces energy consumption and parasitic drag. |

| High-Speed Capability | Enables faster operation and increased output. |

| Extended Component Life | Minimizes wear on shafts, reducing maintenance costs. |

| Broad Temperature Range | Ensures reliable performance in extreme environments. |

| Excellent Chemical Resistance | Prevents failure when sealing aggressive fluids. |

Ready to enhance your machinery's efficiency and reliability?

PTFE seals are a high-performance solution for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. KINTEK specializes in the precision manufacturing of custom PTFE components—from seals and liners to labware—tailored to your specific needs, whether for prototypes or high-volume orders.

Let our expertise help you reduce energy costs, increase operational speeds, and extend equipment lifespan. Contact KINTEK today to discuss your project and request a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems