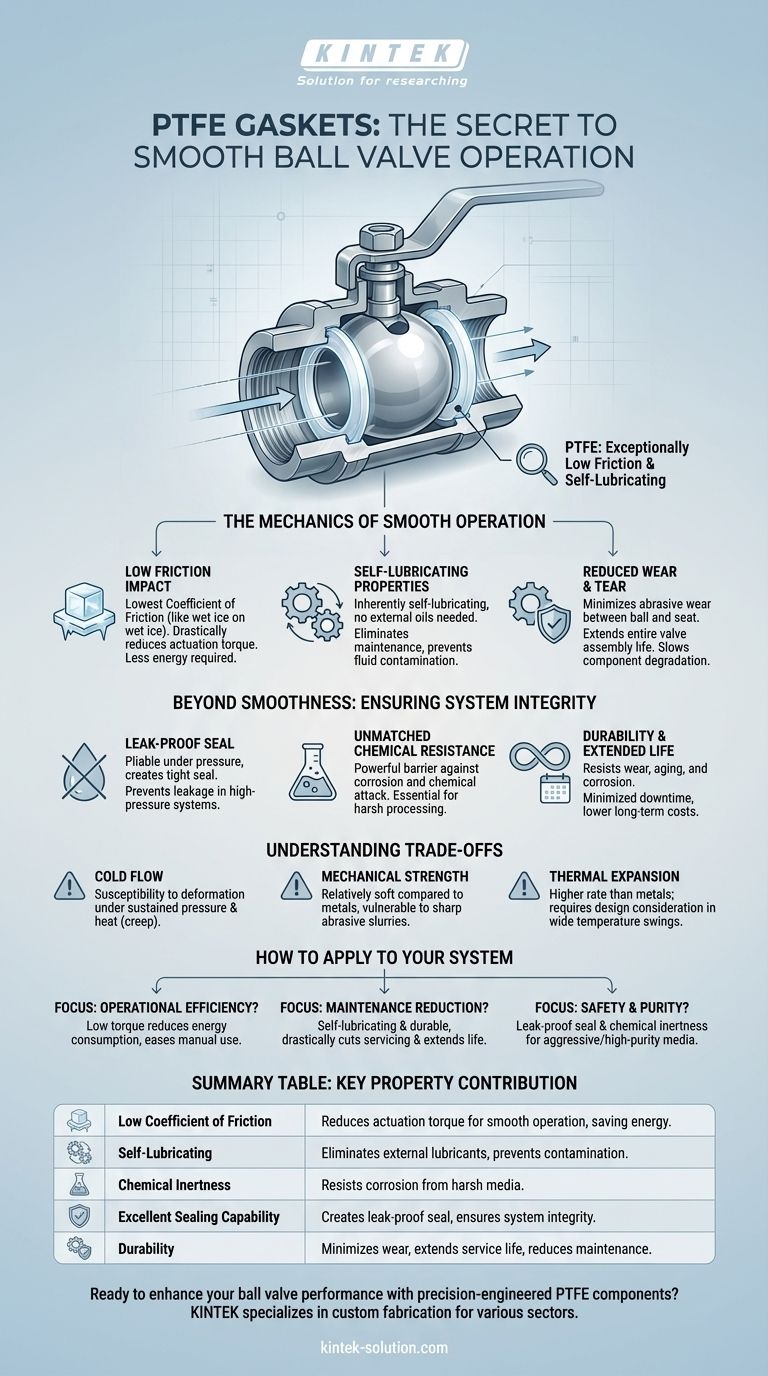

At its core, PTFE (Polytetrafluoroethylene) gaskets enable smooth ball valve operation through their exceptionally low coefficient of friction and self-lubricating nature. This unique combination drastically reduces the force required to turn the valve's ball, minimizing wear on critical components and ensuring consistent, low-torque performance over the valve's entire lifespan.

While the immediate benefit of PTFE is a noticeably smoother valve actuation, its true value lies in how this property, combined with its chemical inertness and sealing capability, creates a highly durable, low-maintenance, and reliable component for critical systems.

The Mechanics of Smooth Operation

The "feel" of a smooth valve is a direct result of PTFE's fundamental material properties. It isn't an additive or a coating, but an inherent characteristic of the material itself.

The Impact of Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This means the ball inside the valve can rotate against the PTFE seats with minimal resistance.

This directly translates to a lower actuation torque, which is the amount of force needed to open or close the valve. For both manual levers and automated pneumatic actuators, this means less energy is required.

Self-Lubricating Properties

PTFE's molecular structure allows it to function without any external lubrication. This is a critical advantage.

The self-lubricating nature eliminates a common maintenance task and, more importantly, prevents process fluids from being contaminated by greases or oils.

The Result: Reduced Wear and Tear

The combination of low friction and self-lubrication significantly reduces the abrasive wear between the rotating ball and the stationary PTFE seats.

This extends the operational life of the entire valve assembly, as the components responsible for both sealing and movement degrade at a much slower rate.

Beyond Smoothness: Ensuring System Integrity

While smooth operation is a key performance indicator, the ultimate goal of a valve is reliable control and containment of media. PTFE excels in these areas as well.

Creating a Leak-Proof Seal

PTFE gaskets are pliable enough to deform slightly under pressure, creating an exceptionally tight seal against the valve's ball.

This ensures the integrity of the system by preventing fluid or gas leakage, even in high-pressure applications.

Unmatched Chemical Resistance

The PTFE lining and gaskets provide a powerful barrier that protects the valve's metal body from corrosion and chemical attack.

This is essential in industries like chemical processing and pharmaceuticals, where harsh or abrasive materials could otherwise quickly damage the valve.

Durability and Extended Service Life

The cumulative effect of these properties is a significantly longer service life for the ball valve.

Valves with PTFE components are less prone to wear, aging, or corrosion, leading to minimized downtime and lower long-term maintenance costs.

Understanding the Trade-offs

No material is perfect for every application. To make an informed decision, it's crucial to understand the limitations of standard PTFE.

Susceptibility to "Cold Flow"

Under sustained pressure and elevated temperatures, PTFE can slowly deform over time, a phenomenon known as creep or "cold flow."

This can eventually compromise the seal's integrity, and is a key reason why valve torque settings must be precise.

Lower Mechanical Strength

Compared to metals, PTFE is a relatively soft material. It can be susceptible to damage from highly abrasive media (like slurries with sharp particles) passing through the system.

Thermal Expansion and Contraction

PTFE has a higher rate of thermal expansion than metals. In systems with wide temperature swings, this must be accounted for in the valve's design to maintain a consistent, leak-free seal.

How to Apply This to Your System

The decision to rely on PTFE components should be based on your system's primary operational goals.

- If your primary focus is operational efficiency: The low actuation torque from PTFE reduces energy consumption for automated valves and makes manual operation easier.

- If your primary focus is maintenance reduction: PTFE's self-lubricating nature and inherent durability drastically cut down on routine servicing and extend the valve's service life.

- If your primary focus is system safety and purity: The combination of a reliable, leak-proof seal and exceptional chemical inertness makes PTFE essential for handling aggressive or high-purity media.

Ultimately, PTFE's unique properties make it the cornerstone material for modern, high-performance ball valves that deliver both smooth operation and long-term reliability.

Summary Table:

| Key Property | Contribution to Ball Valve Performance |

|---|---|

| Low Coefficient of Friction | Reduces actuation torque for smooth, easy operation, saving energy. |

| Self-Lubricating | Eliminates need for external lubricants, preventing contamination. |

| Chemical Inertness | Resists corrosion from harsh media, ideal for chemical and pharmaceutical use. |

| Excellent Sealing Capability | Creates a leak-proof seal under pressure, ensuring system integrity. |

| Durability | Minimizes wear on valve components, extending service life and reducing maintenance. |

Ready to enhance your ball valve performance with precision-engineered PTFE components? KINTEK specializes in manufacturing high-quality PTFE seals, gaskets, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get components that deliver smooth operation, leak-proof reliability, and long-term durability.

Contact us today to discuss your specific requirements and let our solutions optimize your system's efficiency and safety!

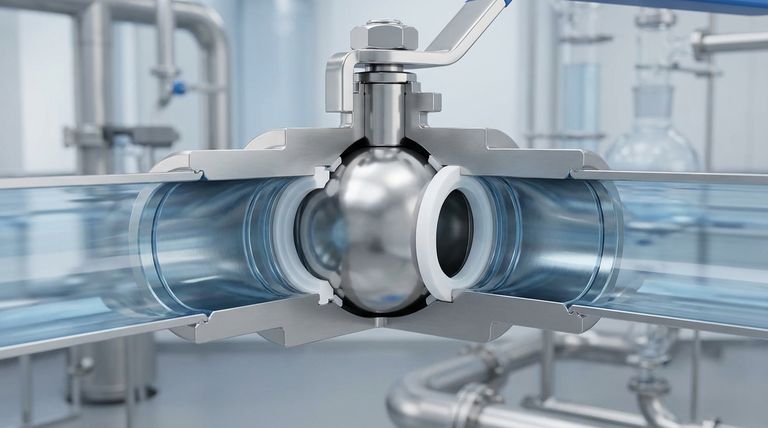

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the key properties of PTFE that make it suitable for bushes? Discover the Ultimate Self-Lubricating Solution

- How does the melting point and thermal stability of PTFE impact its CNC machining? Mastering Heat Control for Precision

- What are the benefits of using EPTFE joint sealant? Achieve Superior Sealing for Demanding Applications

- What are the advantages of PTFE/PFA lined ball valves? Superior Corrosion Resistance & Leak Prevention

- What are the mechanical properties of PTFE O-rings? A Guide to Low Friction, Chemical Resistance, and Trade-offs

- What is FEP and how does it differ from PTFE? Key Differences in Performance & Manufacturing

- Why is PTFE difficult to process using traditional methods? Overcoming High Melt Viscosity

- What are the main applications of PTFE envelope gaskets? Seal Fragile Flanges and Prevent Contamination