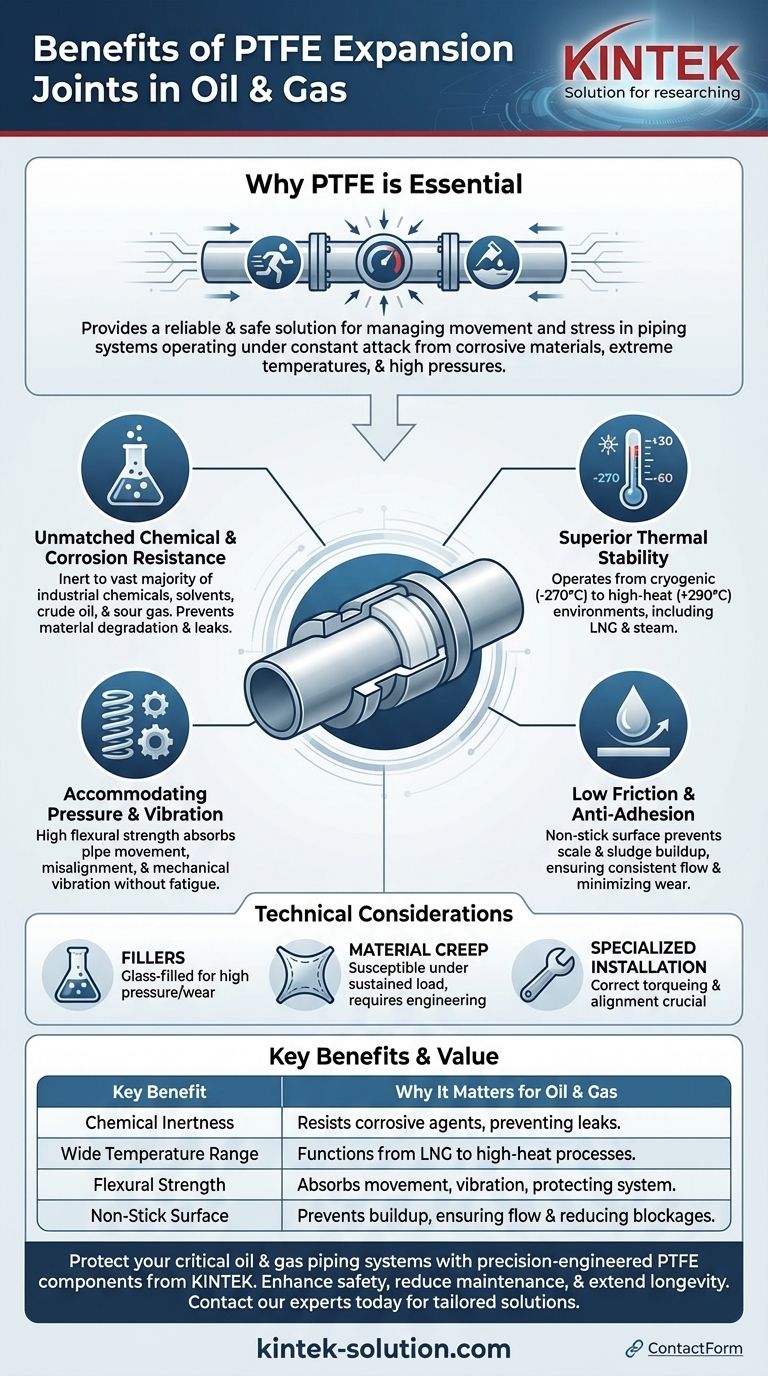

In short, PTFE expansion joints are essential to the oil and gas industry because they provide a reliable and safe solution for managing movement and stress in piping systems that operate under constant attack from corrosive materials, extreme temperatures, and high pressures. Their unique material properties prevent leaks and failures in environments where most other materials would quickly degrade.

The core benefit of PTFE in oil and gas is not merely its survival in harsh conditions, but its ability to deliver unmatched operational reliability. Its combination of chemical inertness, thermal stability, and low friction directly translates to enhanced safety, reduced maintenance, and greater system longevity in critical applications.

Why PTFE is a Requirement, Not an Option

In the oil and gas industry, piping systems are the arteries of any operation. They are subjected to a punishing combination of factors that can easily lead to catastrophic failure.

The Problem: A Uniquely Hostile Environment

Piping systems constantly expand and contract due to thermal cycling. They also experience vibration from pumps and pressure fluctuations from the materials flowing through them. At the same time, they must transport highly corrosive substances like crude oil, sour gas, and aggressive processing chemicals.

The Solution: A Material Built for Extremes

PTFE (Polytetrafluoroethylene) is a fluoropolymer with a set of properties that makes it almost perfectly engineered to solve these challenges. An expansion joint made from PTFE can absorb movement and stress while remaining completely unaffected by the hostile environment, ensuring the integrity of the entire system.

Deconstructing the Core Benefits of PTFE

The value of PTFE expansion joints comes from a few fundamental material characteristics that directly counter the primary threats in oil and gas applications.

Unmatched Chemical and Corrosion Resistance

PTFE is almost entirely chemically inert. It is non-reactive to the vast majority of industrial chemicals, solvents, and corrosive agents found in upstream, midstream, and downstream processes. This prevents material degradation that would lead to leaks and system failure.

Superior Thermal Stability

PTFE maintains its structural integrity and mechanical properties across an exceptionally wide temperature range, typically from -270°C to +290°C (-454°F to +554°F). This makes it ideal for both cryogenic applications like LNG processing and high-temperature environments involving steam or heated hydrocarbons.

Accommodating Pressure and Vibration

With high flexural strength, PTFE expansion joints are designed to repeatedly bend and compress without cracking or fatiguing. This allows them to effectively absorb pipe movement, misalignment, and mechanical vibration, protecting more rigid components of the system from stress.

Low Friction and Anti-Adhesion

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. Its non-stick surface prevents the buildup of deposits, scale, or sludge from the process fluid, ensuring consistent flow and preventing blockages. This also minimizes wear on the joint itself.

Understanding the Trade-offs and Considerations

While highly effective, PTFE is not a universal solution without its own set of technical considerations. Objectivity requires understanding its limitations.

The Role of Fillers

Standard PTFE can sometimes be improved for specific high-pressure or high-wear applications. Materials like glass-filled PTFE are often used for components like valve seals, enhancing compressive strength and rigidity to better withstand extreme pressures.

Potential for Material Creep

Under a constant, sustained load (especially at elevated temperatures), PTFE can be susceptible to "creep," or slow deformation. Proper engineering and design of the expansion joint are critical to account for this and ensure long-term dimensional stability.

Specialized Installation

The performance of a PTFE expansion joint is highly dependent on correct installation. Proper torqueing of bolts and alignment of flanges is necessary to ensure a perfect seal without damaging the PTFE element.

How to Apply This to Your Project

Your choice of material should be guided by the most critical demand of your specific application.

- If your primary focus is corrosion: PTFE is the definitive choice for handling aggressive chemicals, sour gas, or any fluid that would degrade metals and lesser plastics.

- If your primary focus is extreme temperature: PTFE's uniquely wide operating range makes it one of the few materials suitable for both cryogenic and high-heat processes.

- If your primary focus is system reliability: The combination of durability, chemical inertness, and low friction in PTFE minimizes maintenance cycles and reduces the risk of premature failure.

Ultimately, selecting PTFE expansion joints is an investment in the operational integrity and safety of your entire system.

Summary Table:

| Key Benefit | Why It Matters for Oil & Gas |

|---|---|

| Chemical Inertness | Resists corrosive crude oil, sour gas, and processing chemicals, preventing leaks. |

| Wide Temperature Range | Functions reliably from cryogenic LNG (-270°C) to high-heat processes (+290°C). |

| Flexural Strength | Absorbs pipe movement, vibration, and misalignment to protect system components. |

| Non-Stick Surface | Prevents sludge and scale buildup, ensuring consistent flow and preventing blockages. |

Protect your critical oil and gas piping systems with precision-engineered PTFE components from KINTEK.

Our PTFE seals, liners, labware, and custom expansion joints are built to deliver unmatched reliability in the most hostile environments—from upstream exploration to downstream processing. We combine precision manufacturing with deep material expertise to provide solutions that enhance safety, reduce maintenance, and extend system longevity.

Whether you need a custom prototype or high-volume production, KINTEK is your trusted partner for high-performance PTFE fabrication.

Contact our experts today to discuss your specific application requirements and receive a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability