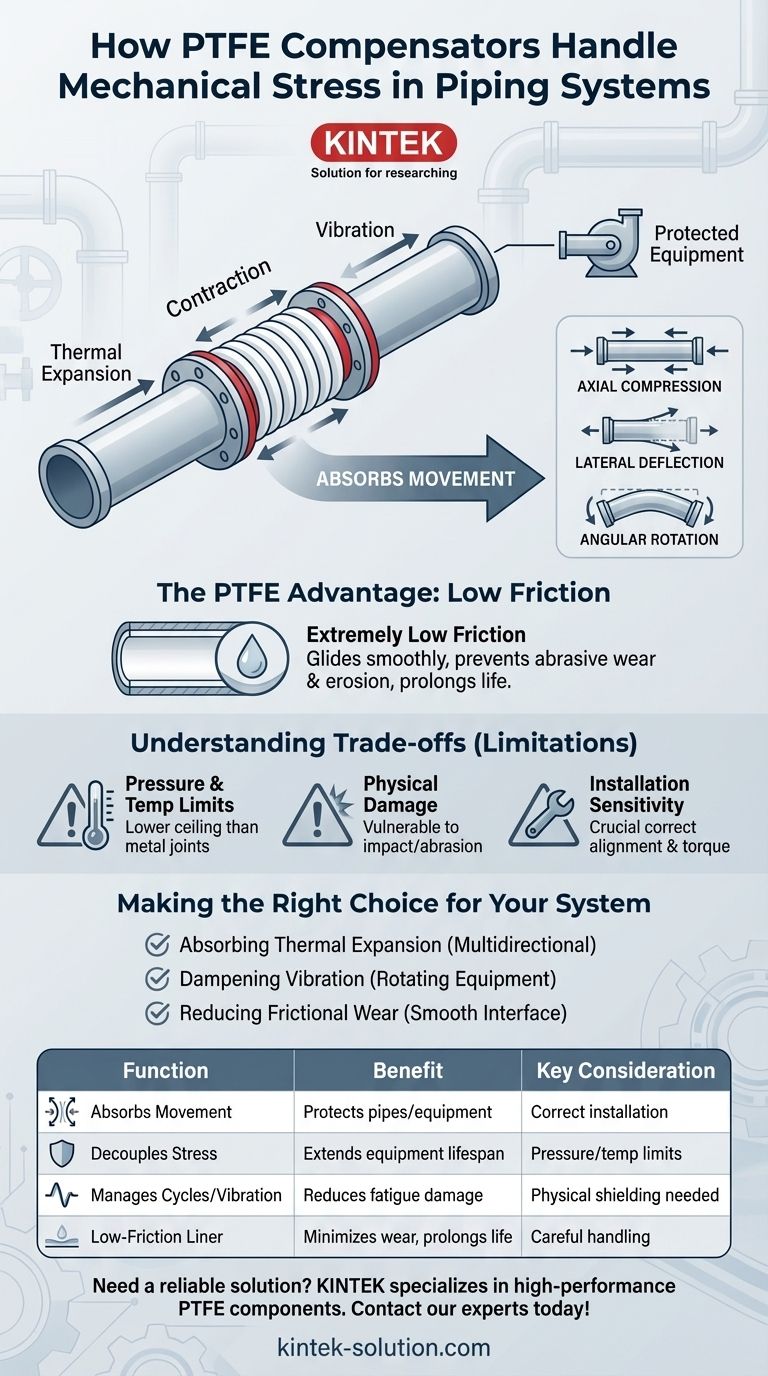

At its core, a PTFE compensator handles mechanical stress by acting as a highly flexible, engineered joint within a piping system. It is specifically designed to absorb movements in multiple directions—such as those caused by thermal expansion, contraction, or equipment vibration—thereby isolating the rigid pipes and connected equipment from potentially damaging forces.

The fundamental role of a PTFE compensator is not to resist stress but to absorb the movement that causes the stress. By decoupling sections of a piping system, it prevents the buildup of forces that lead to pipe fatigue, joint failure, and damage to connected machinery.

The Core Mechanism: Controlled Flexibility

A rigid piping system has almost no tolerance for movement. When pipes heat up, they expand, and when they cool, they contract. Without a point of relief, this thermal cycling generates immense internal stress that can warp pipes, break welds, and damage sensitive equipment like pumps or vessels.

Absorbing Multidirectional Movement

The compensator's primary function is to absorb movement along multiple axes. This includes axial compression (movement along the pipe's length), lateral deflection (side-to-side movement), and angular rotation (bending or twisting). This capability makes it far more versatile than a simple flexible hose.

Decoupling Stress from Equipment

By absorbing these movements, the compensator acts as a buffer. It ensures that the forces generated by a shifting pipe are not transferred to the flanges of a pump, tank, or valve. This isolation is critical for protecting expensive equipment from nozzle load stress.

Managing Thermal Cycles and Vibration

In systems with frequent temperature changes or constant vibration from machinery, the PTFE compensator continuously flexes and adjusts. This dynamic response prevents the cumulative damage of fatigue, which occurs when a material is repeatedly stressed and relaxed over time.

The Unique Advantage of PTFE Material

While many materials can be used for flexible joints, Polytetrafluoroethylene (PTFE) offers distinct properties that enhance its performance in managing mechanical stress.

Extremely Low Friction

The PTFE liner has an exceptionally low coefficient of friction. As the pipe system moves, it glides smoothly within the compensator. This prevents the abrasive wear and surface erosion that can occur with other materials, prolonging the life of the compensator and the adjoining pipes.

Understanding the Trade-offs

While highly effective, PTFE compensators are not a universal solution. Understanding their limitations is key to proper application and avoiding premature failure.

Pressure and Temperature Limits

Compared to metallic expansion joints, PTFE has a lower operating temperature and pressure ceiling. Exceeding these manufacturer-specified limits can lead to material degradation and catastrophic failure.

Susceptibility to Physical Damage

The flexible nature of PTFE means it is more vulnerable to external impact or abrasion than a steel component. Proper shielding and careful handling during installation are necessary in high-traffic or harsh industrial environments.

Installation Sensitivity

The performance and lifespan of a PTFE compensator are highly dependent on correct installation. Misalignment, over-torqued bolts, or improper anchoring of the piping can impose unintended stresses on the compensator, leading to a drastically reduced service life.

Making the Right Choice for Your System

Selecting the right component requires matching its capabilities to your primary operational goal.

- If your primary focus is absorbing thermal expansion in multiple directions: A PTFE compensator is an excellent choice due to its ability to handle complex axial, lateral, and angular movements simultaneously.

- If your primary focus is dampening vibration from rotating equipment: The flexibility of the compensator effectively isolates machinery, preventing vibration from propagating through the entire piping system.

- If your primary focus is reducing frictional wear during movement: The low-friction surface of PTFE provides a smooth, non-abrasive interface that protects pipes and supports from damage.

By correctly applying these components, you can transform harmful mechanical stress into manageable, controlled movement.

Summary Table:

| Function | Benefit | Key Consideration |

|---|---|---|

| Absorbs Axial, Lateral, and Angular Movement | Protects pipes and equipment from stress | Must be installed correctly to avoid misalignment |

| Decouples Stress from Equipment | Extends lifespan of pumps, valves, and tanks | Lower pressure/temperature limits than metal joints |

| Manages Thermal Cycles and Vibration | Reduces cumulative fatigue damage | Susceptible to physical impact without shielding |

| Low-Friction PTFE Liner | Minimizes abrasive wear and prolongs service life | Requires careful handling during installation |

Need a reliable solution for mechanical stress in your piping system?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom compensators designed to absorb movement, isolate vibration, and protect your critical equipment. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a compensator that meets your exact specifications.

Protect your investment and enhance system longevity. Contact our experts today to discuss your application requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key industries that rely on PTFE rotary shaft seals? Critical Sealing for Extreme Environments

- What forms can PTFE be manufactured into? Explore Versatile Shapes from Seals to Complex Parts

- What are PTFE rotary lip seals and what applications are they used for? High-Performance Sealing Solutions

- Why is it important to specify reinforcement requirements when selecting PTFE materials? Ensure Component Performance & Reliability

- How can the bore design of a PTFE seal be modified for higher speed or pressure? Optimize for Extreme Conditions

- Why is PTFE an ideal material for bellows applications? Achieve Superior Sealing & Flexibility

- What is the wall thickness range for PTFE encapsulated O-rings? Optimize Seal Performance and Chemical Resistance

- What are the benefits of low friction in PTFE lined valves? Achieve Smoother Operation and Lower Costs