PTFE coatings benefit industrial manufacturing by creating highly durable, low-friction, and chemically inert surfaces. This unique combination protects equipment from corrosion and wear, significantly reduces maintenance needs, and enhances overall operational efficiency in a wide range of applications.

The core value of Polytetrafluoroethylene (PTFE) lies in its ability to solve multiple, distinct operational challenges simultaneously. It acts as a protective shield against chemical attack, a non-stick surface to prevent buildup, and a lubricant to reduce friction, leading to longer equipment life and lower operating costs.

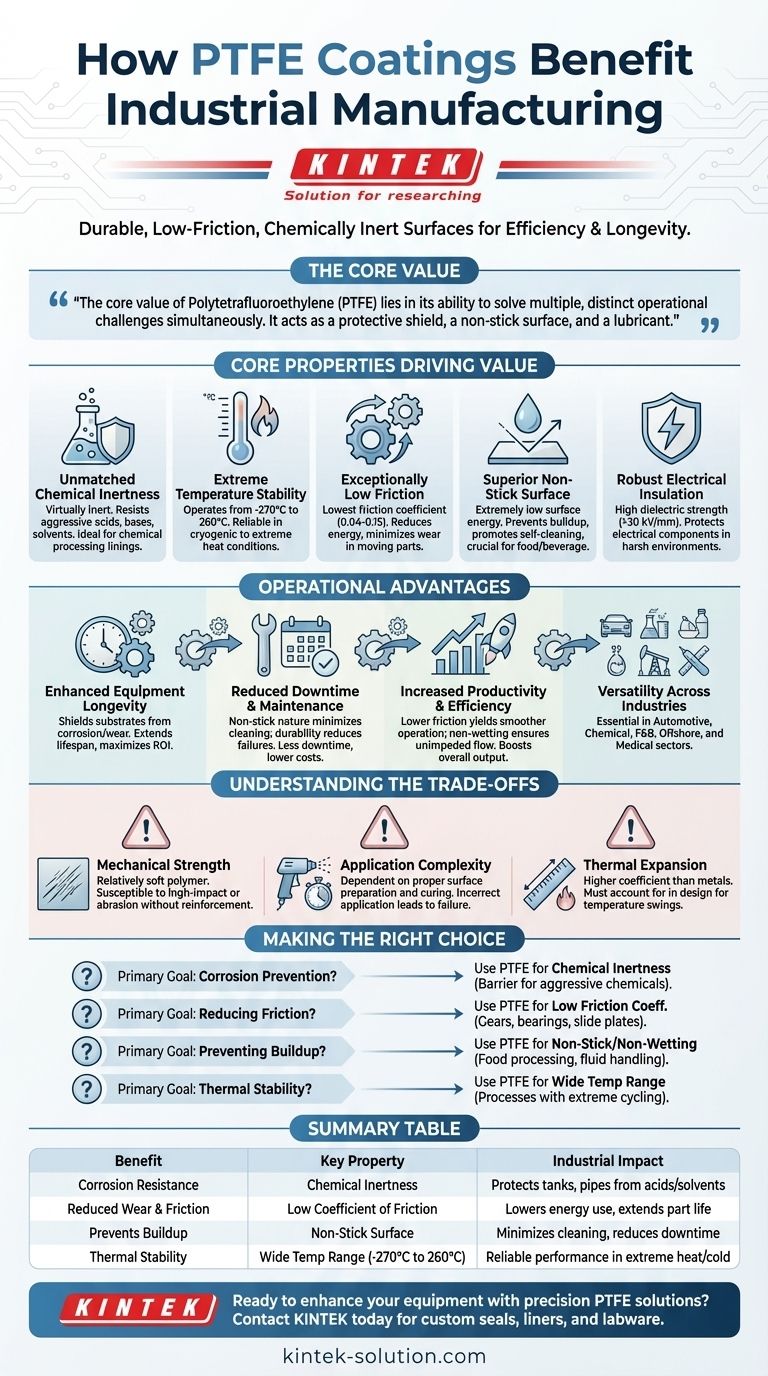

The Core Properties Driving PTFE's Value

To understand the benefits of PTFE coatings, it is essential to first understand the fundamental properties of the material itself. These characteristics are the source of its widespread adoption in demanding industrial environments.

Unmatched Chemical Inertness

PTFE is virtually inert and does not react with the vast majority of industrial chemicals, including aggressive acids, bases, and solvents.

This makes it an ideal lining for tanks, pipelines, and vessels used in chemical processing, safeguarding the equipment from corrosion.

Extreme Temperature Stability

PTFE coatings maintain their integrity and performance across an exceptionally wide temperature range, typically from -270°C to 260°C (-454°F to 500°F).

This stability allows components to function reliably in processes involving extreme heat or cryogenic conditions without degrading.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice (0.04 to 0.15).

This property is critical for applications involving moving parts, such as gears and slide plates, where it reduces energy consumption and minimizes wear.

Superior Non-Stick and Non-Wetting Surface

The material's surface energy is extremely low, which means other substances do not adhere to it easily.

This non-stick and non-wetting characteristic is crucial in the food and beverage industry and also promotes self-cleaning in fluid handling systems, preventing clogs and contamination.

Robust Electrical Insulation

PTFE is an excellent electrical insulator with a high dielectric strength (exceeding 30 kV/mm). This makes it valuable for protecting electrical components in harsh environments.

Translating Properties into Operational Advantages

These inherent properties directly translate into tangible, high-impact benefits for industrial manufacturing operations.

Enhanced Equipment Longevity

By shielding metal substrates from corrosion and reducing wear between moving parts, PTFE coatings dramatically extend the lifespan of critical equipment.

This leads to a higher return on capital investment and fewer replacements over time.

Reduced Downtime and Maintenance

The non-stick nature of PTFE minimizes the need for frequent cleaning, while its durability reduces the frequency of part failure.

Both factors contribute directly to less operational downtime and lower associated maintenance costs.

Increased Productivity and Efficiency

In mechanical systems, lower friction means smoother, more efficient operation. In fluid systems, such as fuel or hydraulic lines, the non-wetting surface ensures unimpeded flow.

These performance enhancements boost overall productivity and process consistency.

Versatility Across Industries

The unique combination of properties makes PTFE coatings essential in numerous sectors, including automotive, chemical processing, food and beverage, offshore operations, and medical research.

Understanding the Trade-offs

While highly effective, PTFE coatings are not a universal solution. An objective assessment requires acknowledging their limitations.

Mechanical Strength

PTFE is a relatively soft polymer. In applications with high-impact forces or severe physical abrasion, the coating can be susceptible to scratching or wear without specialized reinforcement.

Application Complexity

The performance of a PTFE coating is highly dependent on proper surface preparation and the curing process. Incorrect application can lead to poor adhesion and premature failure.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than most metals. This difference must be accounted for in the design of components that will experience significant temperature swings to avoid stress and delamination.

Making the Right Choice for Your Application

To leverage PTFE effectively, align its primary strengths with your specific operational goal.

- If your primary focus is corrosion prevention: PTFE's chemical inertness makes it the ideal barrier for equipment handling aggressive chemicals.

- If your primary focus is reducing friction: Its exceptionally low friction coefficient is perfect for improving the efficiency of moving parts like gears, bearings, and slide plates.

- If your primary focus is preventing material buildup: The non-stick and non-wetting properties are critical for applications in food processing, molding, and fluid handling to ensure clean operation.

- If your primary focus is thermal stability: Its ability to perform reliably across a vast temperature range makes it suitable for processes involving extreme thermal cycling.

Ultimately, integrating PTFE coatings is a strategic decision to enhance equipment resilience, streamline operations, and reduce long-term costs.

Summary Table:

| Benefit | Key Property | Industrial Impact |

|---|---|---|

| Corrosion Resistance | Chemical Inertness | Protects tanks, pipes from acids/solvents |

| Reduced Wear & Friction | Low Coefficient of Friction | Lowers energy use, extends part life |

| Prevents Buildup | Non-Stick Surface | Minimizes cleaning, reduces downtime |

| Thermal Stability | Wide Temp Range (-270°C to 260°C) | Reliable performance in extreme heat/cold |

Ready to enhance your equipment's performance with precision PTFE solutions?

At KINTEK, we specialize in manufacturing high-quality PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment benefits from superior corrosion resistance, reduced friction, and extended service life, leading to lower operational costs and increased productivity.

Contact us today to discuss your specific needs, from prototypes to high-volume orders, and discover how our PTFE coatings can solve your toughest manufacturing challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE rotary seals over traditional rubber seals? Superior Performance in Extreme Conditions

- What are alternatives to Teflon sheets for heat press? Parchment Paper vs. Silicone vs. Teflon

- Why are PTFE ring gaskets still preferred despite their disadvantages? For Unmatched Chemical & Thermal Resistance

- What are the electrical applications of PTFE sheets? Unlock Superior Insulation for Demanding Electronics

- What makes ePTFE sheets a preferred material in the food, beverage, and pharmaceutical sectors? Ensuring Product Purity and Safety

- At what low temperature does PTFE Teflon O-ring still maintain compressive plasticity? Achieve Reliable Sealing to Near Absolute Zero

- What properties can ceramics provide in PTFE-based laminates? Enhance Thermal, Mechanical & Electrical Performance

- What materials are used in the construction of PTFE-lined bearings? A Guide to Their 4-Layer Composite Design