The fundamental difference is that graphite packing has high thermal conductivity, while PTFE packing has very low thermal conductivity. This means graphite excels at dissipating frictional heat away from a shaft, whereas PTFE acts as an insulator, trapping heat.

The choice between PTFE and graphite packing is a critical engineering decision that hinges on heat management. Graphite is the solution for high-speed, high-temperature applications due to its ability to conduct heat, while PTFE is the choice for chemically aggressive environments where heat generation is not the primary concern.

The Core Difference: Heat Management

The most significant distinction between these two materials is how they handle the heat generated by friction in dynamic applications like pumps and mixers. This single property often dictates which material is suitable for a given task.

Graphite Packing: The Conductor

Graphite, a natural form of pure carbon, is an excellent thermal conductor. This property allows it to actively pull heat away from the rotating shaft and dissipate it through the stuffing box.

This heat dissipation is critical for preventing overheating, which can lead to premature packing failure and shaft damage. Its ability to manage heat makes it the superior choice for high-speed and high-temperature services.

PTFE Packing: The Insulator

PTFE (polytetrafluoroethylene) is a synthetic polymer with very low thermal conductivity. Instead of dissipating heat, it acts as an insulator, trapping heat directly at the shaft surface.

In applications with high shaft speeds, this heat buildup can quickly exceed PTFE's operational temperature limit, causing the packing to fail and potentially score the shaft.

Beyond Thermal Properties: A Head-to-Head Comparison

While thermal conductivity is a primary differentiator, a full comparison requires looking at the operational limits and strengths of each material.

Temperature Resistance

Graphite has a significantly wider and higher temperature range, operating effectively from -400°F to 850°F.

PTFE has a more limited range, suitable for applications from -300°F to 500°F.

Chemical Resistance

This is PTFE's standout advantage. It is exceptionally resistant to nearly all chemicals, acids, gases, and corrosive substances, with the rare exception of molten alkali metals.

Graphite offers good chemical resistance but is not as universally inert as PTFE, making PTFE the default choice for the most aggressive chemical services.

Friction and Self-Lubrication

Graphite is naturally self-lubricating, which helps reduce friction and wear from the start.

PTFE is known for having one of the lowest coefficients of friction of any solid material. It is non-conductive and protects against shaft wear, but often requires lubrication for optimal performance in a packing format.

Physical Strength

PTFE packing exhibits a much higher tensile strength at 2,000 PSI, compared to graphite packing at 650 PSI. This can contribute to its durability in high-pressure, low-speed applications.

Understanding the Trade-offs

Choosing the wrong material based on a single property can lead to rapid equipment failure. It's crucial to understand the compromises you are making.

The Risk of Overheating with PTFE

Using PTFE in a high-speed pump is a common but critical mistake. Its inability to dissipate heat means frictional energy builds up, which can melt the packing and damage the equipment.

The Limits of Graphite's Inertness

While thermally robust, graphite is not a universal solution for every chemical. In highly aggressive media where PTFE is the only material that won't degrade, the application must be designed to operate at lower speeds to accommodate PTFE's thermal limitations.

Contamination and Color Transfer

Graphite packing is black and can shed carbon particles. This makes it unsuitable for industries like food, beverage, and pharmaceuticals, where product purity is paramount.

In these cases, white, non-contaminating PTFE is the only acceptable option, regardless of its thermal properties.

How to Apply This to Your Project

Your operational goal is the single most important factor in selecting the right packing material.

- If your primary focus is high-speed or high-temperature performance: Choose graphite packing for its unmatched ability to dissipate destructive frictional heat.

- If your primary focus is resistance to aggressive chemicals: Choose PTFE packing for its superior chemical inertness, but be mindful of the operational speed and temperature.

- If your primary focus is preventing product contamination: Choose white PTFE packing to ensure purity and avoid the color transfer associated with black graphite.

Ultimately, a successful seal is achieved by precisely matching the packing's material properties to the specific demands of your application.

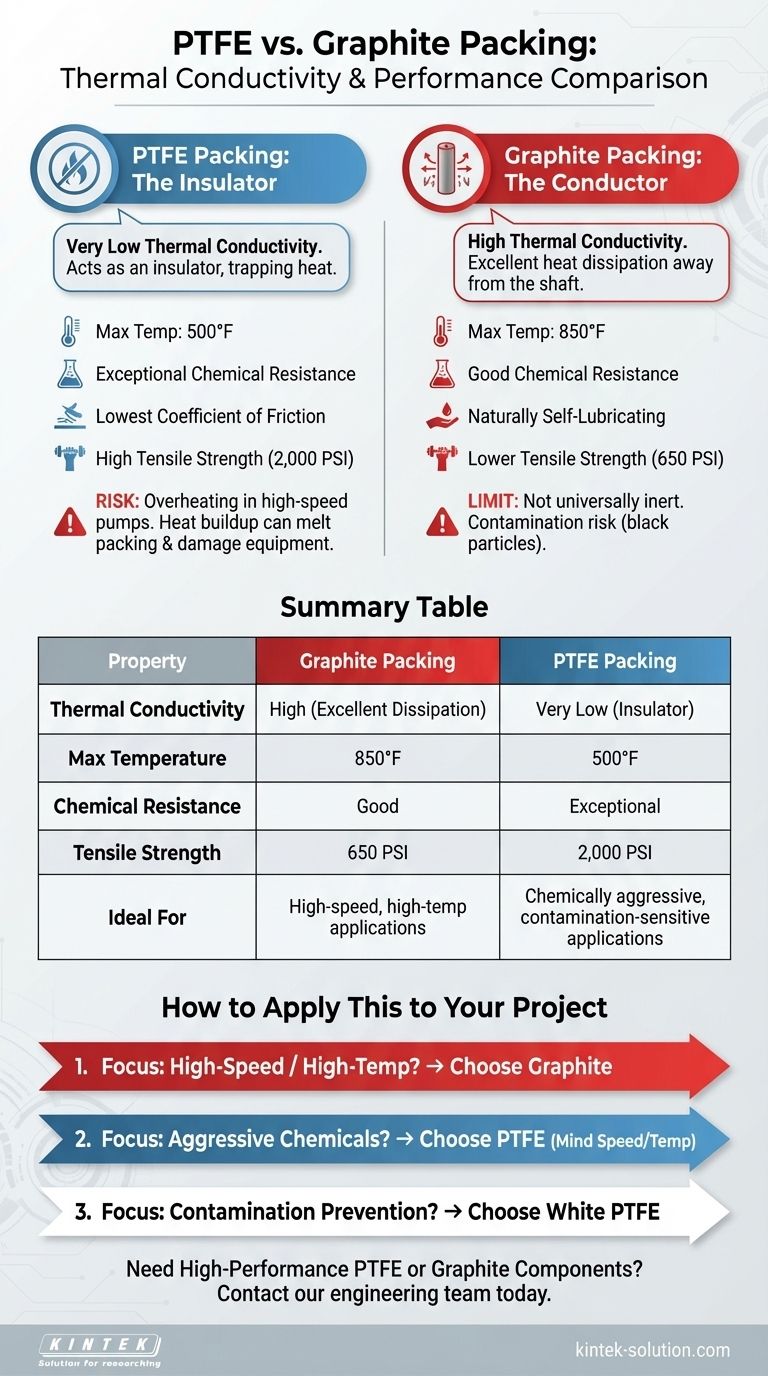

Summary Table:

| Property | Graphite Packing | PTFE Packing |

|---|---|---|

| Thermal Conductivity | High (Excellent heat dissipation) | Very Low (Acts as an insulator) |

| Max Temperature | 850°F | 500°F |

| Chemical Resistance | Good | Exceptional |

| Tensile Strength | 650 PSI | 2,000 PSI |

| Ideal For | High-speed, high-temperature applications | Chemically aggressive, contamination-sensitive applications |

Need High-Performance PTFE or Graphite Components?

Choosing the right sealing material is critical for your equipment's performance and longevity. KINTEK specializes in the precision manufacturing of PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We understand the nuanced properties of these advanced materials and can help you select or fabricate the ideal solution, from prototypes to high-volume production runs. Let our expertise ensure your application runs efficiently and reliably.

Contact our engineering team today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components