In short, fillers transform PTFE from a soft, pliable material into a high-performance engineering plastic. They are added to dramatically improve mechanical properties—most notably wear and creep resistance—that are inherently poor in pure, or "virgin," PTFE. This enhancement allows PTFE to be used in demanding applications like bearings, seals, and structural components.

The core purpose of adding fillers to PTFE is to overcome its mechanical weaknesses. While pure PTFE is prized for its extreme chemical inertness and low friction, it deforms easily and wears quickly. Fillers provide a structural backbone, making the material stronger and more durable at the cost of certain electrical and chemical properties.

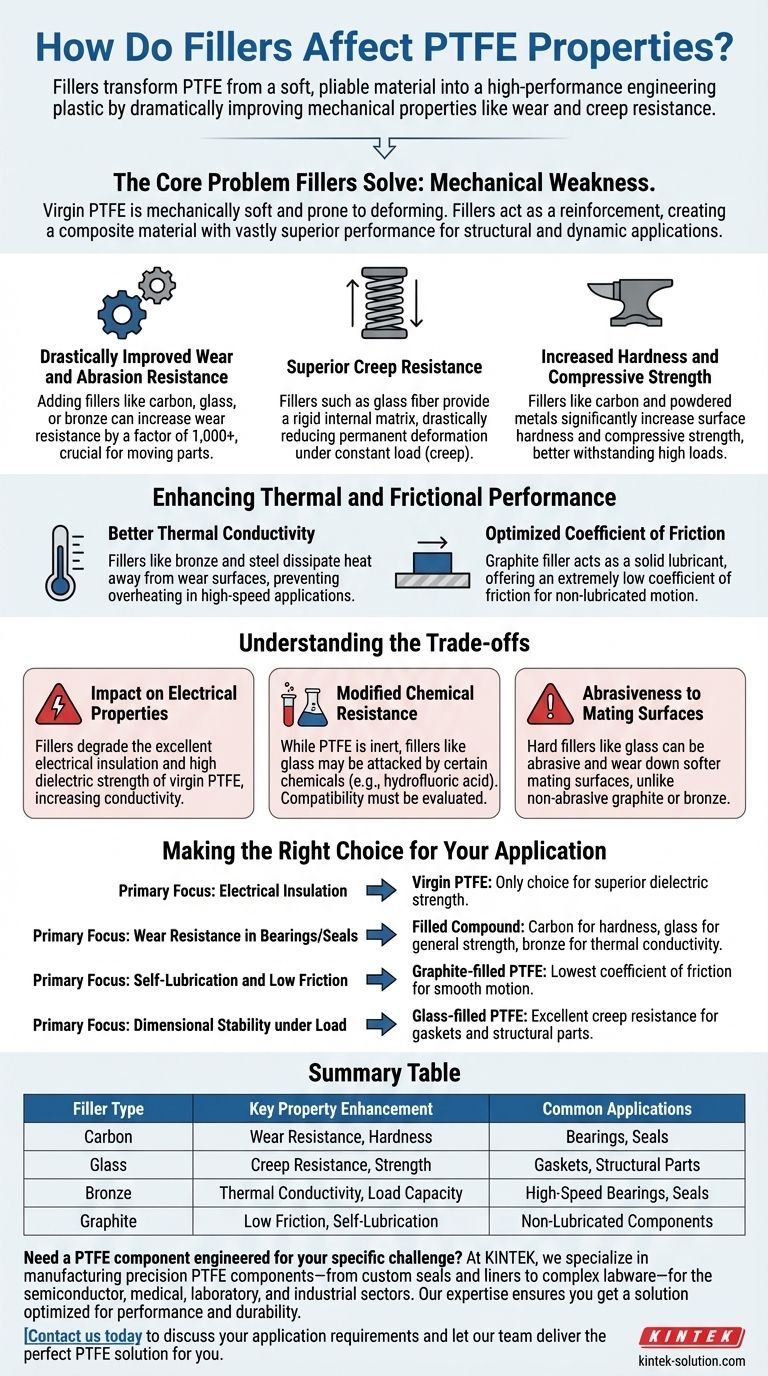

The Core Problem Fillers Solve: Mechanical Weakness

Virgin PTFE is mechanically soft and prone to deforming under load over time. Fillers act as a reinforcement, creating a composite material with vastly superior performance characteristics for structural and dynamic applications.

Drastically Improved Wear and Abrasion Resistance

Pure PTFE, despite its low friction, wears away very quickly when subjected to rubbing or abrasive forces.

Adding fillers like carbon, glass, or bronze can increase wear resistance by a factor of 1,000 or more. This is the single most significant enhancement for applications involving moving parts.

Superior Creep Resistance

Creep is the tendency of a material to deform permanently under a constant load, a significant weakness of virgin PTFE.

Fillers such as glass fiber provide a rigid internal matrix. This structural support drastically reduces creep, allowing filled PTFE to be used for seals and gaskets that must maintain their shape under pressure to prevent leaks.

Increased Hardness and Compressive Strength

Fillers like carbon and powdered metals significantly increase the surface hardness and compressive strength of PTFE. This makes the material better able to withstand high loads without being crushed or indented.

Enhancing Thermal and Frictional Performance

Beyond raw strength, fillers are crucial for managing heat and optimizing the frictional properties of PTFE for specific environments.

Better Thermal Conductivity

Virgin PTFE is an excellent thermal insulator, which can be a problem in high-speed applications where friction generates heat.

Fillers like bronze and steel are highly conductive and help dissipate this heat away from the wear surface. This prevents overheating and premature failure in bearings and dynamic seals.

Optimized Coefficient of Friction

While pure PTFE is known for being incredibly slick, certain fillers can enhance this property even further for specific uses.

Graphite is a key example. It acts as a solid lubricant, giving graphite-filled PTFE an extremely low coefficient of friction, which is ideal for non-lubricated, smooth-running components.

Understanding the Trade-offs

Adding fillers is not a universal upgrade. The improvements in mechanical properties come at the cost of other characteristics, and it is critical to understand these compromises.

The Impact on Electrical Properties

This is the most significant trade-off. Virgin PTFE is one of the best electrical insulators available, with a very high dielectric strength.

Nearly all fillers degrade this property, increasing electrical conductivity and making filled PTFE unsuitable for high-voltage insulation. Some fillers, like carbon, are added specifically to make the material static-dissipative.

Modified Chemical Resistance

While the PTFE polymer itself remains highly inert, the filler material may not be.

A glass-filled PTFE, for example, will be attacked by hydrofluoric acid or strong alkalis that do not affect the PTFE matrix. The chemical compatibility of the entire composite must be evaluated for the intended environment.

Abrasiveness to Mating Surfaces

Hard fillers can damage the surfaces they run against. For instance, glass-filled PTFE is abrasive and can wear down softer mating surfaces like aluminum shafts.

In contrast, fillers like graphite and bronze are non-abrasive and better suited for protecting softer metal components.

Making the Right Choice for Your Application

The choice between virgin and filled PTFE—and which filler to use—depends entirely on the primary demands of your application.

- If your primary focus is electrical insulation: Virgin (unfilled) PTFE is the only choice due to its superior dielectric strength.

- If your primary focus is wear resistance in bearings or seals: A filled compound is essential; consider carbon for hardness, glass for general-purpose strength, or bronze for thermal conductivity.

- If your primary focus is self-lubrication and low friction: A graphite-filled PTFE offers one of the lowest coefficients of friction for smooth, non-lubricated motion.

- If your primary focus is dimensional stability under load: A glass-filled PTFE provides excellent creep resistance, making it ideal for gaskets and structural parts.

By understanding these filler-driven properties, you can select a PTFE compound precisely engineered for your specific challenge.

Summary Table:

| Filler Type | Key Property Enhancement | Common Applications |

|---|---|---|

| Carbon | Wear Resistance, Hardness | Bearings, Seals |

| Glass | Creep Resistance, Strength | Gaskets, Structural Parts |

| Bronze | Thermal Conductivity, Load Capacity | High-Speed Bearings, Seals |

| Graphite | Low Friction, Self-Lubrication | Non-Lubricated Components |

Need a PTFE component engineered for your specific challenge?

At KINTEK, we specialize in manufacturing precision PTFE components—from custom seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require the superior insulation of virgin PTFE or the enhanced mechanical properties of a filled compound, our expertise in custom fabrication from prototypes to high-volume orders ensures you get a solution optimized for performance and durability.

Contact us today to discuss your application requirements and let our team deliver the perfect PTFE solution for you.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How is PTFE formed? Unlocking the Secrets of Its Exceptional Properties

- What are the benefits of carbon-filled PTFE? Enhance Strength, Wear & Conductivity

- How has PTFE demonstrated effectiveness in industrial case studies? Proven Solutions for Harsh Environments

- What is the chemical compatibility of PTFE? The Ultimate Guide to Chemical Resistance

- Is PTFE the same as Teflon? Understanding the Brand vs. Material Distinction

- How is ePTFE structured and what are its properties? Unlock Advanced Performance with Microporous PTFE

- What are the properties of pure PTFE material? Unlock Superior Chemical & Thermal Performance

- Which industries commonly use PTFE due to its special properties? Solve Critical Engineering Challenges