In short, expanded PTFE gaskets deliver exceptional sealing performance. Their effectiveness stems from a unique combination of extreme softness, high compressibility, and near-universal chemical inertness, allowing them to create a reliable seal even on irregular or delicate surfaces where other materials fail.

The core reason for expanded PTFE's sealing power is its ability to flow into microscopic surface imperfections under very low clamping force. This makes it a superior choice for sealing flawed, warped, or fragile flanges, particularly in chemically aggressive environments.

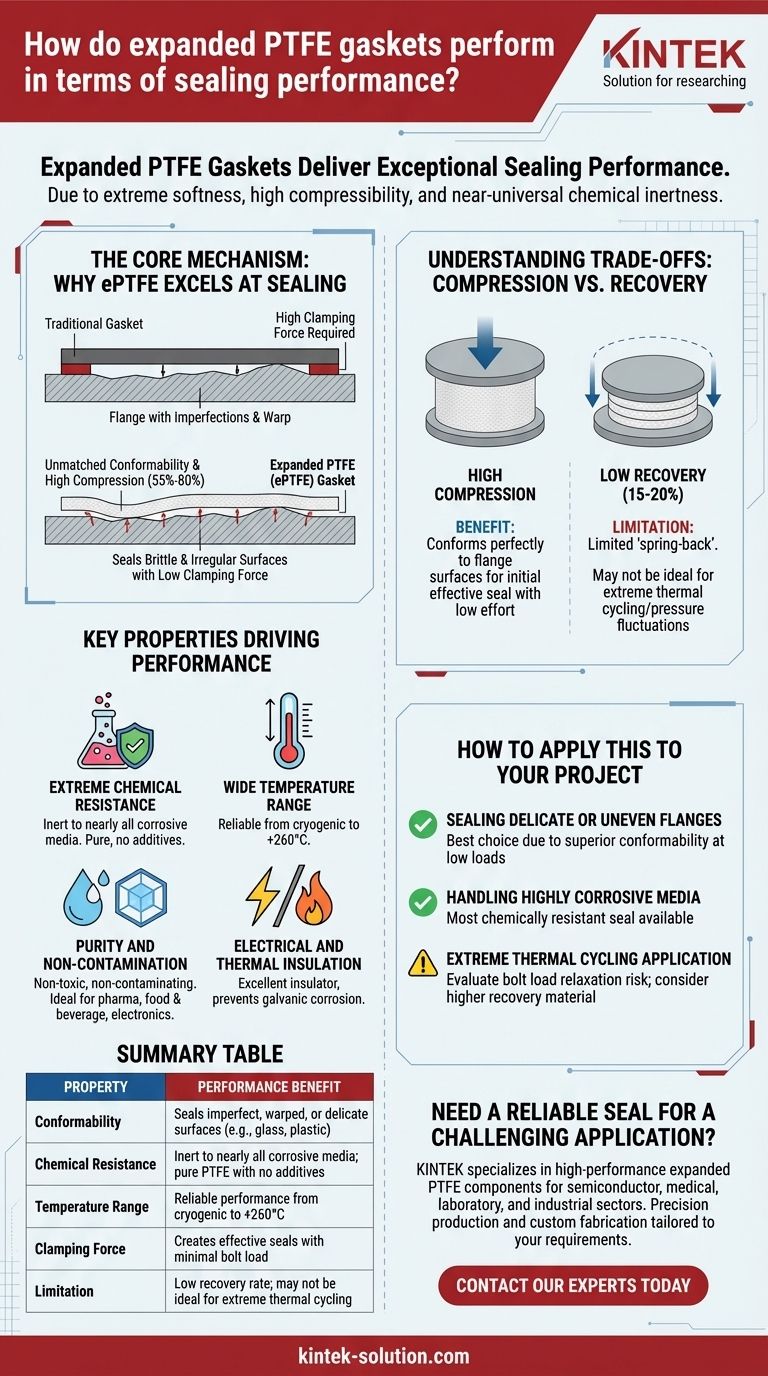

The Core Mechanism: Why Expanded PTFE Excels at Sealing

The performance of a gasket is defined by its ability to create and maintain a seal between two stationary surfaces. Expanded PTFE (ePTFE) accomplishes this through a unique physical structure.

Unmatched Conformability

Expanded PTFE is exceptionally soft and has a very high compression ratio, typically between 55% and 80%. When compressed, the material easily flows into and fills microscopic cracks, scratches, and other imperfections on a flange face.

This effectively compensates for deviations caused by machining, installation displacement, or uneven preload, ensuring a tight seal across the entire surface.

Sealing Brittle and Irregular Surfaces

Many industrial applications use equipment made from brittle materials like glass, porcelain, graphite, or plastic. Applying the high bolt torque required for traditional gaskets would risk cracking these flanges.

Because ePTFE is so soft, it achieves a reliable seal with minimal clamping force, protecting the integrity of delicate or large-diameter equipment.

Key Properties Driving Performance

Beyond its mechanical ability to fill gaps, ePTFE possesses several innate properties that make it a premier sealing material for demanding applications.

Extreme Chemical Resistance

Made from pure, synthetic fluoropolymer, expanded PTFE contains no additives. It is unaffected by nearly all corrosive liquids, vapors, and gases, ensuring the gasket itself does not degrade or fail when exposed to aggressive media.

Wide Temperature Range

This material maintains its integrity and sealing capability across a broad thermal spectrum, performing reliably from cryogenic temperatures all the way up to +260°C.

Purity and Non-Contamination

Expanded PTFE is non-toxic, non-contaminating, and resistant to aging. This makes it an ideal choice for industries like pharmaceuticals, food and beverage, and electronics, where protecting the purity of the process medium is critical.

Electrical and Thermal Insulation

The material is an excellent electrical and thermal insulator. This property is highly valuable for applications requiring the electrical isolation of pipeline flanges to prevent galvanic corrosion.

Understanding the Trade-offs: Compression vs. Recovery

No material is perfect for every situation. The greatest strength of expanded PTFE—its high compressibility—is also linked to its primary limitation.

The Benefit of High Compression

As discussed, the high compression ratio is what allows ePTFE to conform perfectly to flange surfaces, creating an initial, highly effective seal with very little effort.

The Limitation of Low Recovery

Expanded PTFE exhibits a low recovery rate, or "spring-back," typically between 15% and 20%. Once compressed, it does not readily return to its original shape.

This can be a drawback in applications with significant thermal cycling or pressure fluctuations. As flanges expand and contract, bolt load can relax, and a gasket with low recovery may not be able to expand to fill the resulting gap, potentially leading to a leak.

How to Apply This to Your Project

Choosing the right gasket requires matching the material's properties to the specific demands of your service conditions.

- If your primary focus is sealing delicate or uneven flanges: Expanded PTFE is an excellent choice due to its superior conformability under low bolt loads, which protects equipment from damage.

- If your primary focus is handling highly corrosive media: The pure, inert nature of expanded PTFE provides one of the most chemically resistant seals available.

- If your primary focus is an application with extreme thermal cycling: Carefully evaluate the risk of bolt load relaxation; a gasket material with a higher recovery rate might be necessary to maintain a long-term seal.

Ultimately, understanding both the strengths and limitations of expanded PTFE empowers you to deploy it where it will perform best.

Summary Table:

| Property | Performance Benefit |

|---|---|

| Conformability | Seals imperfect, warped, or delicate surfaces (e.g., glass, plastic) |

| Chemical Resistance | Inert to nearly all corrosive media; pure PTFE with no additives |

| Temperature Range | Reliable performance from cryogenic to +260°C |

| Clamping Force | Creates effective seals with minimal bolt load |

| Limitation | Low recovery rate; may not be ideal for extreme thermal cycling |

Need a reliable seal for a challenging application?

KINTEK specializes in manufacturing high-performance expanded PTFE components, including seals and gaskets, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a gasket perfectly tailored to your specific requirements, whether you're dealing with corrosive chemicals, delicate equipment, or uneven surfaces.

Contact our experts today to discuss your project and discover the ideal PTFE solution for your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the key design features of PTFE bushings? Achieve Maintenance-Free, High-Performance Bearing Solutions

- What are the main advantages of using Teflon bushings across different industries? Achieve Maintenance-Free Performance

- Why is the non-stick surface of PTFE bushings beneficial? For Contamination-Free, Low-Maintenance Performance

- In which industries is RPTFE particularly suitable for throttle valves? Ensure Purity and Durability

- What are the two main methods for manufacturing pure PTFE gaskets? Molding vs. Cutting Explained

- What makes PTFE seals suitable for high-temperature applications? Unmatched Thermal & Chemical Stability

- What temperature range can custom Teflon rotary shaft seals withstand? Master Extreme Heat & Cryogenic Cold

- What are the cost-related advantages of PTFE sliding pipe supports? Reduce Total Cost of Ownership