The most direct way to improve PTFE gaskets is by incorporating fillers or metal inserts during manufacturing. These additions fundamentally enhance the material's mechanical properties, creating a gasket that is far more resistant to the common failure points of standard, unfilled (virgin) PTFE, such as cold flow and blowout.

While standard PTFE offers unmatched chemical resistance, its inherent softness can lead to failure under pressure and temperature. The solution is not to find a different material, but to reinforce the PTFE itself with fillers or metal to overcome these mechanical weaknesses.

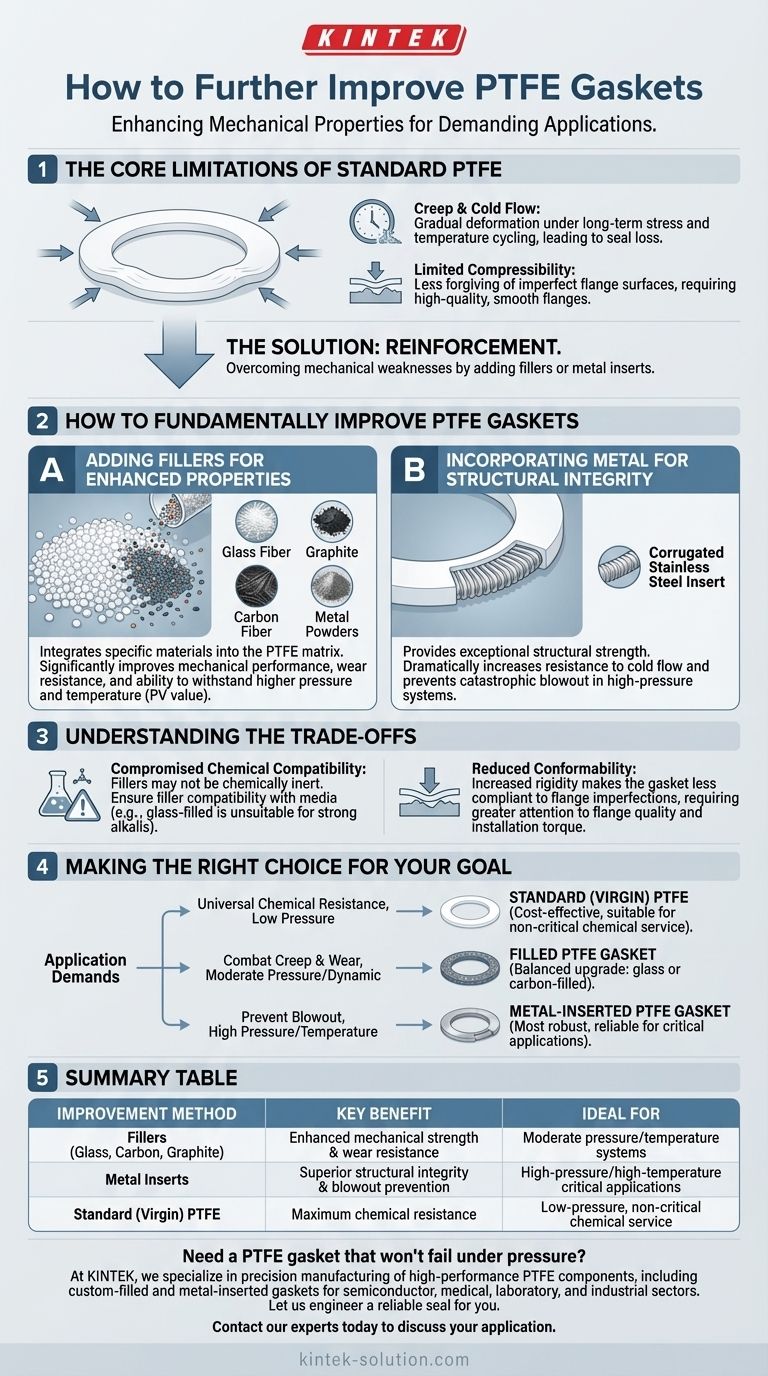

The Core Limitations of Standard PTFE

To understand why enhancements are necessary, we must first recognize the inherent limitations of standard Polytetrafluoroethylene (PTFE). While its chemical inertness is a significant advantage, its mechanical properties present challenges in demanding applications.

The Problem of Creep and Cold Flow

Standard PTFE is a relatively soft material. When subjected to long-term stress from flange pressure and temperature cycling, it can gradually deform.

This phenomenon, known as creep or cold flow, causes the gasket to thin out and lose its sealing force over time. This can ultimately lead to leaks and connection failure.

The Challenge of Limited Compressibility

PTFE is not as compressible as elastomeric materials like rubber. This makes it less forgiving of imperfect or uneven flange surfaces.

Achieving a tight, reliable seal with a standard PTFE gasket requires clean, smooth, and perfectly aligned flanges, which may not always be practical in industrial settings.

How to Fundamentally Improve PTFE Gaskets

Reinforcing the PTFE material addresses its mechanical shortcomings directly, expanding its operational range and reliability.

Adding Fillers for Enhanced Properties

The most common method of improvement is mixing PTFE resin with specific filler materials before it is molded.

These fillers, such as glass fiber, graphite, carbon fiber, or metal powders, become integrated into the PTFE matrix. This significantly improves mechanical performance, wear resistance, and the ability to withstand higher pressures and temperatures (PV value) while largely maintaining PTFE's excellent chemical resistance.

Incorporating Metal for Structural Integrity

For the highest-demand applications, a metal-inserted PTFE gasket provides the ultimate solution for preventing deformation.

Typically, a corrugated or perforated stainless steel insert is encapsulated within the PTFE. This metal core provides exceptional structural strength, dramatically increasing resistance to cold flow and, most critically, preventing catastrophic gasket blowout in high-pressure systems.

Understanding the Trade-offs

While reinforcing PTFE is highly effective, it introduces important trade-offs that must be considered for proper material selection.

Compromised Chemical Compatibility

The primary trade-off is a potential reduction in universal chemical resistance. While the PTFE itself remains inert, the filler material may not be.

For example, glass-filled PTFE is not suitable for use with strong alkalis or hydrofluoric acid. You must ensure that both the PTFE and the specific filler are compatible with the media being sealed.

Reduced Conformability

Adding fillers or a metal core makes the gasket more rigid. This increased rigidity is excellent for resisting pressure but makes the gasket less able to conform to flange imperfections.

Using a reinforced PTFE gasket requires greater attention to flange quality and proper installation torque to achieve an effective initial seal.

Making the Right Choice for Your Goal

Selecting the correct gasket depends entirely on the specific demands of your application.

- If your primary focus is universal chemical resistance in low-pressure systems: Standard, unfilled PTFE is often the most cost-effective and suitable choice.

- If you need to combat creep and wear in moderate-pressure or dynamic applications: A filled PTFE gasket (e.g., glass or carbon-filled) offers a balanced upgrade in performance.

- If your primary focus is preventing blowout and ensuring seal integrity in high-pressure or high-temperature environments: A metal-inserted PTFE gasket is the most robust and reliable option.

- If you need to maximize the lifespan of any gasket type: Always prioritize proper storage, meticulous installation procedures, and regular inspection of the flanged connection.

Choosing the right gasket formulation is the critical first step toward achieving a safe and reliable seal.

Summary Table:

| Improvement Method | Key Benefit | Ideal For |

|---|---|---|

| Fillers (Glass, Carbon, Graphite) | Enhanced mechanical strength & wear resistance | Moderate pressure/temperature systems |

| Metal Inserts | Superior structural integrity & blowout prevention | High-pressure/high-temperature critical applications |

| Standard (Virgin) PTFE | Maximum chemical resistance | Low-pressure, non-critical chemical service |

Need a PTFE gasket that won't fail under pressure?

At KINTEK, we specialize in precision manufacturing of high-performance PTFE components, including custom-filled and metal-inserted gaskets for the semiconductor, medical, laboratory, and industrial sectors. We overcome the limitations of standard PTFE by engineering solutions tailored to your specific pressure, temperature, and chemical requirements—from prototypes to high-volume orders.

Let us engineer a reliable seal for you. Contact our experts today to discuss your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection