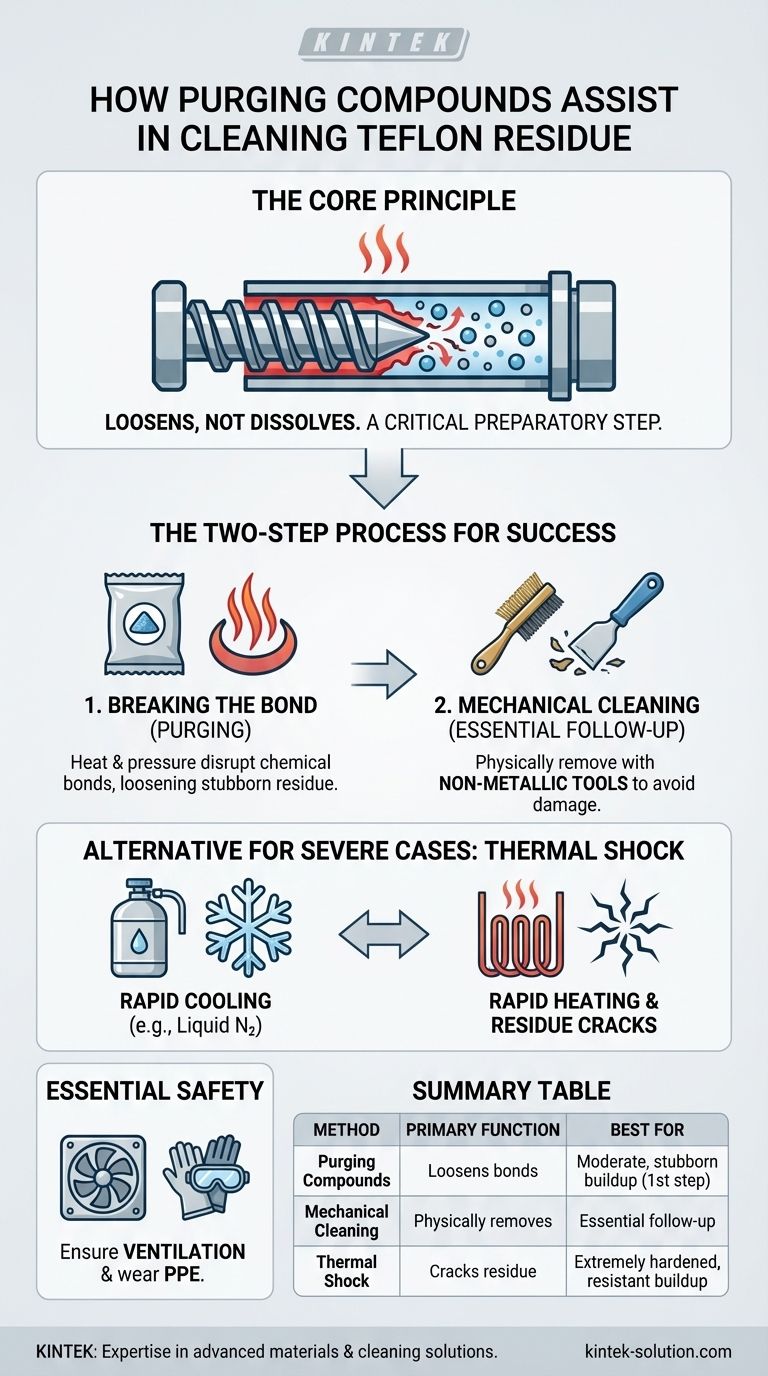

To be direct, purging compounds do not dissolve Teflon residue, but they are a critical first step in removing it. They are specifically formulated to break up and loosen stubborn Teflon buildup within processing machinery like screws and barrels, transforming it into a state that is far easier to remove through subsequent mechanical cleaning.

The core principle to understand is that purging compounds are a preparatory tool, not a complete solution. Their primary function is to weaken the Teflon's adhesion, paving the way for effective manual or mechanical removal.

The Role of Purging Compounds in Teflon Removal

Effectively removing Teflon is a multi-step process. Relying on a single method often leads to frustration and incomplete cleaning, which is why understanding the specific role of each step is crucial for success.

How They Work: Breaking the Bond

Purging compounds are designed to work under heat and pressure inside the machine. As they are processed, their active ingredients penetrate the layers of burnt-on or degraded Teflon, disrupting the chemical and physical bonds holding the residue to the metal surfaces.

This action effectively loosens the residue, breaking large, stubborn patches into smaller, more manageable particles.

The Critical Follow-Up: Mechanical Cleaning

Once the purging compound has done its job, the loosened Teflon must be physically removed. This is a non-negotiable step.

Use soft, non-metallic tools like brass brushes or scrapers to clean the screw and barrel. Using harder, metallic tools risks scratching or damaging the equipment, which can create new sites for residue to build up in the future.

An Alternative for Severe Cases: The Thermal Shock Method

When residue is exceptionally stubborn and resistant to purging compounds, the thermal shock method offers a powerful alternative.

The Principle of Rapid Temperature Change

This technique involves rapidly cooling the equipment, often with liquid nitrogen, and then quickly reheating it. The drastic temperature swing causes the metal and the Teflon to expand and contract at different rates.

This differential in expansion and contraction forces the Teflon residue to crack and delaminate from the metal surface, making it significantly easier to scrape or brush away.

Essential Safety Protocols

Working with high temperatures, chemicals, and specialized equipment demands a strict adherence to safety. Overlooking these steps can expose personnel to risk and damage expensive machinery.

Ensure Proper Ventilation

Always work in a well-ventilated area. Heating Teflon and purging compounds can release fumes, and proper airflow is essential to prevent the buildup of potentially harmful vapors.

Wear Personal Protective Equipment (PPE)

Appropriate PPE is mandatory. This includes heat-resistant gloves, safety glasses or a face shield, and any other gear necessary to protect against chemical exposure and high temperatures.

Making the Right Choice for Your Goal

Your cleaning strategy should match the severity of the residue buildup.

- If you are dealing with moderate, stubborn residue: Begin with a high-quality purging compound to loosen the material, followed by a thorough mechanical cleaning with non-metallic tools.

- If the residue is extremely hardened and resistant: Consider the thermal shock method as your primary approach to crack the material before attempting mechanical removal.

- If you are performing routine maintenance: Regular mechanical cleaning after each run may be sufficient to prevent the severe buildup that requires more aggressive methods.

Ultimately, successful Teflon removal relies on using the right tool for each stage of the problem.

Summary Table:

| Method | Primary Function | Best For |

|---|---|---|

| Purging Compounds | Loosens and breaks up residue bonds | Moderate, stubborn buildup as a first step |

| Mechanical Cleaning | Physically removes loosened material | Essential follow-up after purging |

| Thermal Shock | Cracks residue via rapid temperature change | Extremely hardened, resistant buildup |

Struggling with stubborn Teflon residue in your processing equipment? KINTEK understands the critical need for precision cleaning to maintain product quality and equipment longevity in demanding industries like semiconductor, medical, and laboratory manufacturing. Our high-purity PTFE components are engineered for superior performance, but we also know that proper maintenance is key.

Let our expertise in advanced materials and fabrication guide you to the right solution. Contact KINTEK today to discuss your specific challenges and discover how we can support your operational excellence.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials