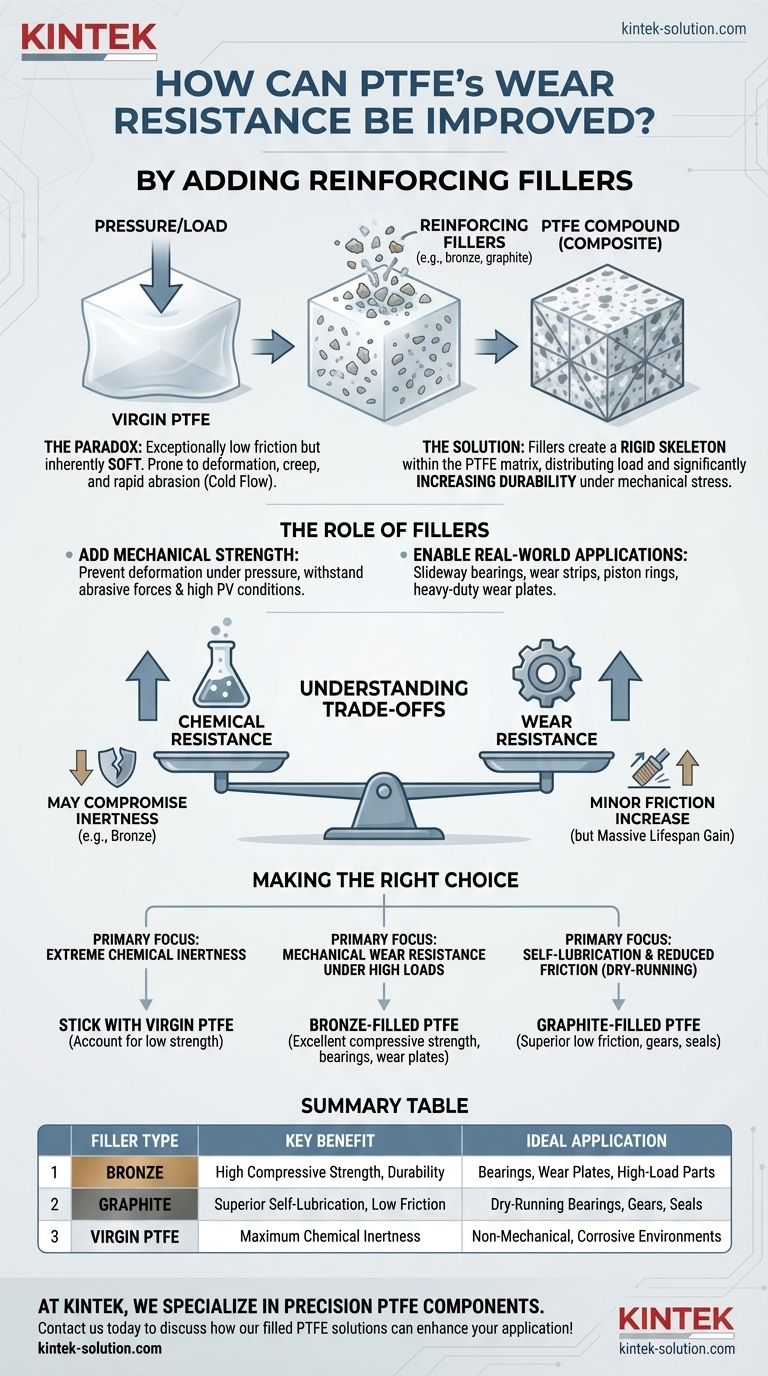

To significantly improve PTFE's wear resistance, you must add reinforcing fillers to create a composite material, often called a PTFE compound. The most common fillers, such as graphite or bronze, act as a structural matrix within the soft PTFE, dramatically increasing its durability under mechanical stress and friction.

While pure PTFE offers exceptional low-friction and self-lubricating properties, it is inherently soft. The key to unlocking its potential in high-wear applications is to reinforce it with fillers, creating a composite that marries PTFE's slickness with the filler's strength.

Why Virgin PTFE Needs Reinforcement

Understanding why pure Polytetrafluoroethylene (PTFE) needs modification requires looking at its two defining, yet conflicting, properties: its low friction and its low mechanical strength.

The Paradox of a Low-Friction Material

PTFE has one of the lowest coefficients of friction of any known solid material. This inherent "slipperiness" is what makes it a valuable component for sliding and rotating parts.

However, this same material is also very soft. Under significant pressure or load, pure PTFE can deform, "creep," or abrade away quickly, a process known as cold flow.

The Self-Lubricating Advantage

The benefit of using PTFE as a base material is its self-lubricating nature. It reduces the energy needed for movement between surfaces.

This property makes it an ideal foundation for wear-resistant components like bearings and gears, provided its structural weakness can be overcome.

The Role of Fillers in PTFE Compounds

Adding fillers is not just about mixing materials; it's about creating a new composite with enhanced properties. The filler provides a rigid skeleton that supports the PTFE matrix.

How Fillers Add Mechanical Strength

Fillers distribute the load across the material's surface, preventing the soft PTFE from deforming under pressure.

This reinforcement drastically reduces the rate of wear, allowing the material to withstand abrasive forces and high-pressure velocity (PV) conditions that would destroy virgin PTFE.

Real-World Applications

The success of filled PTFE is evident in its widespread industrial use.

You will find these compounds in slideway bearings for machine tools, wear strips in shock absorbers, piston rings for sealing and absorbing wear, and heavy-duty wear plates in structural applications.

Understanding the Trade-offs

Enhancing one property of a material often means compromising on another. Filled PTFE is no exception, and understanding these trade-offs is critical for proper material selection.

Impact on Chemical Resistance

Virgin PTFE is one of the most chemically inert materials available. Its resistance is nearly total across its operating temperature range.

However, adding a filler like bronze can compromise this inertness. The bronze itself can react with corrosive chemicals that pure PTFE would easily resist, making the compound unsuitable for certain aggressive environments.

Changes to Friction and Lubricity

While the primary goal is to improve wear resistance, the coefficient of friction may slightly increase compared to virgin PTFE.

The harder filler particles create a different surface dynamic. However, for most mechanical applications, the massive gain in lifespan far outweighs any minor increase in friction.

Making the Right Choice for Your Application

Selecting the correct PTFE formulation depends entirely on the specific demands of your project. The balance between wear resistance, chemical compatibility, and load-bearing capacity is key.

- If your primary focus is extreme chemical inertness: Stick with virgin PTFE, but design your component to account for its low mechanical strength and susceptibility to creep.

- If your primary focus is mechanical wear resistance under high loads: A bronze-filled PTFE compound provides excellent compressive strength and durability, making it ideal for bearings and wear plates.

- If your primary focus is self-lubrication and reduced friction in dry-running conditions: A graphite-filled PTFE compound offers a superior balance of low friction and improved wear resistance.

By selecting the right filler, you transform PTFE from a soft polymer into a high-performance material engineered for durability.

Summary Table:

| Filler Type | Key Benefit | Ideal Application |

|---|---|---|

| Bronze | High Compressive Strength, Durability | Bearings, Wear Plates, High-Load Parts |

| Graphite | Superior Self-Lubrication, Low Friction | Dry-Running Bearings, Gears, Seals |

| Virgin PTFE | Maximum Chemical Inertness | Non-Mechanical, Corrosive Environments |

Need a custom PTFE component that balances wear resistance, chemical inertness, and performance?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our custom fabrication expertise ensures your parts meet exact specifications for durability and performance.

Contact us today to discuss how our filled PTFE solutions can enhance your application!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability