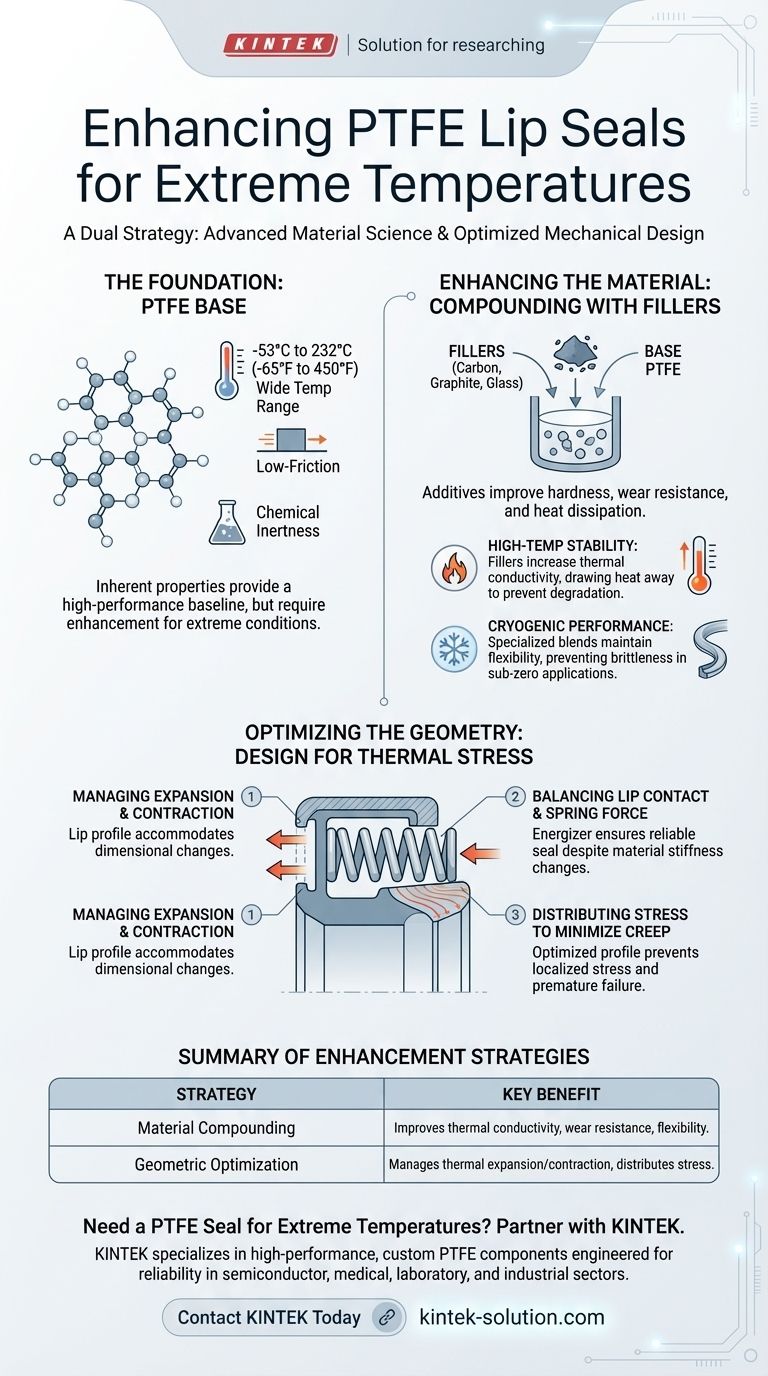

To enhance PTFE lip seals for extreme temperature performance, engineers employ a dual strategy of advanced material science and optimized mechanical design. This involves incorporating specialized fillers like carbon or glass into the PTFE matrix to improve its thermal properties and refining the seal's geometry to manage the physical stresses caused by temperature fluctuations.

While standard PTFE is known for its wide operating temperature range, achieving reliability in extreme high or low-temperature applications is not an inherent property of the base polymer. It requires a deliberate engineering process that combines custom material compounds with a seal design that actively compensates for thermal expansion, contraction, and material stiffness changes.

The Foundation: Why PTFE is the Starting Point

Before enhancing the material, it's critical to understand why PTFE is the preferred foundation for demanding temperature applications. Its inherent properties provide a high-performance baseline that other materials cannot match.

Inherent Thermal Resilience

PTFE's molecular structure gives it a remarkably wide standard operating temperature range, typically from -53°C to 232°C (-65°F to 450°F). This allows it to function where common elastomers would become brittle or degrade.

Low-Friction Operation

PTFE has one of the lowest coefficients of friction of any solid material. This is crucial in dynamic applications, as it minimizes self-generated heat at the sealing point, reducing thermal load and extending seal life, especially at high speeds.

Chemical Inertness

In many applications, such as chemical processing or aerospace, extreme temperatures are combined with aggressive media. PTFE's resistance to most chemicals ensures the seal's integrity is not compromised by its environment.

Enhancing the Material: Compounding with Fillers

The primary method for pushing PTFE beyond its standard limits is the addition of filler materials. These additives are blended into the base PTFE to augment its properties.

The Role of Fillers

Fillers compensate for PTFE's natural weaknesses, such as its tendency to creep under load and its relatively low thermal conductivity. By adding fillers, the compound's hardness, wear resistance, and ability to dissipate heat can be dramatically improved.

Fillers for High-Temperature Stability

For high-temperature environments, fillers like carbon, graphite, and fiberglass are common. These materials increase the compound's thermal conductivity, allowing heat to be drawn away from the sealing lip more effectively, which prevents thermal degradation.

Fillers for Cryogenic Performance

In sub-zero applications, the primary goal is to maintain the seal's flexibility and prevent it from becoming brittle. Specialized polymer blends and specific fillers are used to ensure the lip can conform to the shaft surface even at extreme cold.

Optimizing the Geometry: Design for Thermal Stress

Material science alone is not enough. The physical design of the lip seal must be engineered to function reliably across a wide temperature spectrum.

Managing Expansion and Contraction

All materials expand when heated and contract when cooled. The seal's geometry, particularly the lip profile and flex section, must be designed to accommodate these dimensional changes without losing the precise contact pressure needed to maintain a seal.

Balancing Lip Contact and Spring Force

An energizer, typically a metal spring, provides the consistent force needed for the lip to seal effectively. The design must balance the spring force with the lip's contact area to ensure a reliable seal as the PTFE material becomes softer at high temperatures or stiffer at low temperatures.

Distributing Stress to Minimize Creep

At elevated temperatures, PTFE is more susceptible to "creep," or permanent deformation under load. An optimized seal profile distributes the spring and system pressure forces evenly across the lip, preventing localized stress points that can lead to premature failure.

Understanding the Trade-offs

Enhancing PTFE seals for temperature is a process of balancing competing factors. It is critical to understand the potential downsides of any modification.

Filler Impact on Mating Surfaces

Hard fillers like fiberglass or certain minerals can increase the abrasiveness of the seal lip. This may require the use of hardened or coated shafts to prevent scoring and ensure the longevity of the entire sealing system.

Chemical Resistance Modifications

While the PTFE base is highly inert, some fillers may have less resistance to certain aggressive chemicals. The filler material must be carefully selected to be compatible with both the temperature range and the application media.

Cost vs. Performance

Custom-compounded, filled PTFE seals are a premium engineering solution. Their cost is higher than that of standard elastomer or unfilled PTFE seals, a trade-off that is justified by their superior performance and reliability in demanding applications.

Making the Right Choice for Your Application

Selecting the correct enhancement depends entirely on your specific operational goal.

- If your primary focus is high-temperature stability (e.g., engines, industrial processing): Prioritize seals with carbon, graphite, or glass fillers to enhance thermal conductivity and prevent material degradation.

- If your primary focus is cryogenic performance (e.g., aerospace, LNG systems): Specify custom polymer blends and seal geometries engineered to retain flexibility and prevent brittleness at sub-zero temperatures.

- If you are managing both extreme temperatures and high speeds: Select a low-friction filler like graphite and ensure the seal design is optimized to minimize heat generation at the dynamic sealing surface.

- If operating in a harsh chemical environment at temperature: Verify that both the PTFE base and the chosen filler are fully compatible with the specific media to avoid premature failure.

Ultimately, achieving reliable sealing in extreme temperatures depends on a holistic approach that precisely matches the material science to the mechanical design of the seal.

Summary Table:

| Enhancement Strategy | Key Benefit | Typical Fillers/Features |

|---|---|---|

| Material Compounding | Improves thermal conductivity, wear resistance, and flexibility. | Carbon, Graphite, Glass (high-temp); Polymer Blends (cryogenic) |

| Geometric Optimization | Manages thermal expansion/contraction and distributes stress. | Custom lip profile, balanced spring force, stress-diffusing design |

Need a PTFE Seal for Extreme Temperatures? Partner with KINTEK.

Your demanding applications in the semiconductor, medical, laboratory, and industrial sectors require seals that won't fail under thermal stress. KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—precisely engineered for reliability in extreme environments.

We combine advanced material science with precision production to deliver solutions that meet your exact specifications, from prototypes to high-volume orders. Let us enhance your equipment's performance and longevity.

Contact KINTEK today to discuss your custom PTFE sealing needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the advantages of compression molding for PTFE? Unlock Superior Performance for Large, Dense Components

- What are the benefits of glass and MoS2-filled PTFE? Achieve Superior Performance in Demanding Applications

- What are the advantages of using PTFE gaskets? Achieve Superior Chemical and Thermal Sealing

- What factors should be considered when selecting a PTFE expansion joint? Ensure System Integrity and Safety

- What is PTFE and why is it suitable for O-rings? Achieve Unmatched Chemical & Temperature Resistance

- How does the spring energizer work in PTFE seals? Ensure Leak-Free Performance in Extreme Conditions

- How do metal bellows compare to PTFE bellows? Choose the Right Material for Your Application

- What is a PTFE spacer and what problem does it solve? Achieve Leak-Free Seals in Demanding Environments