The most common way to modify Polytetrafluoroethylene (PTFE) is by compounding it with fillers like glass fiber, carbon, or bronze to enhance its mechanical properties. This process improves characteristics such as wear resistance, strength, and resistance to deformation under load, while retaining PTFE's exceptional chemical inertness and low-friction surface.

Pure PTFE offers incredible chemical, thermal, and electrical resistance, but it is mechanically soft. Modifications are almost always performed to overcome these physical limitations, tailoring the material for specific high-performance applications like bearings, seals, and high-load components.

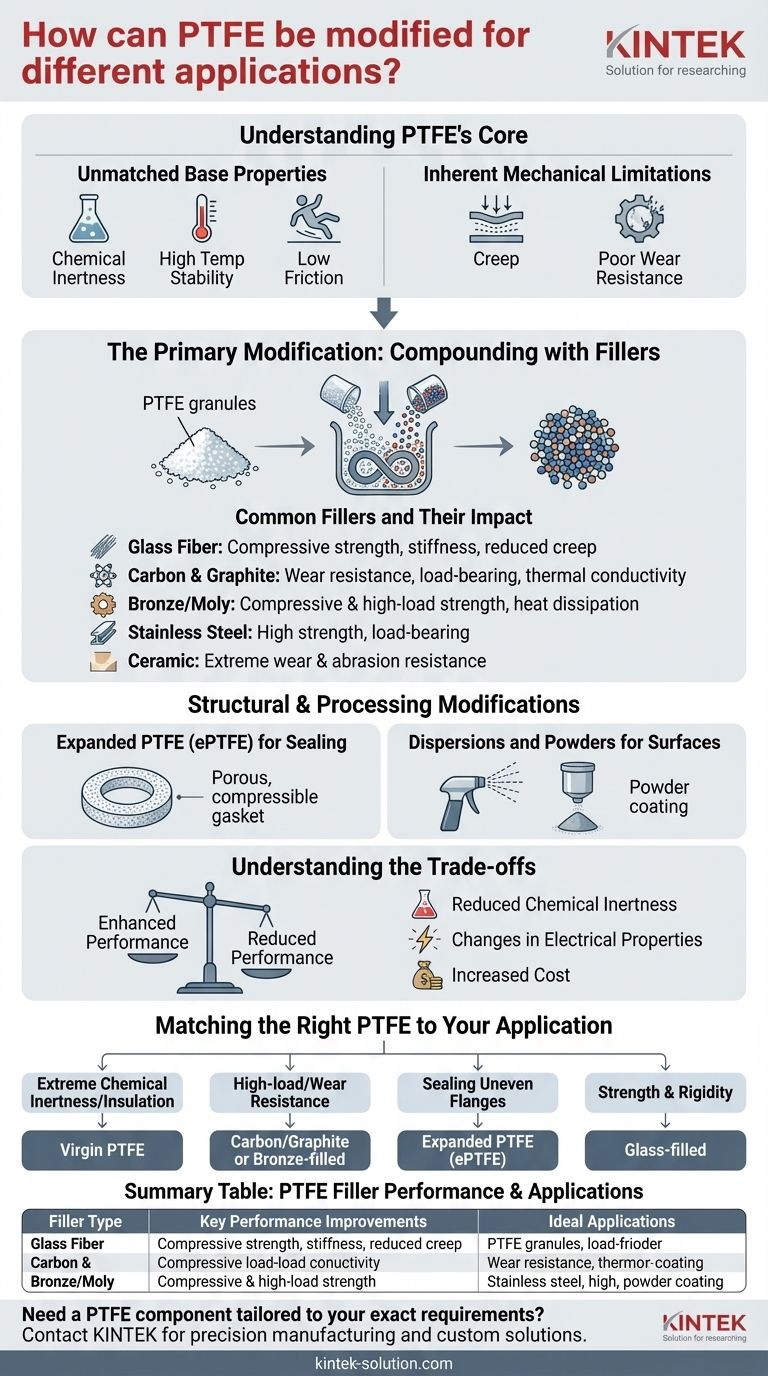

Understanding PTFE's Core Strengths and Weaknesses

To appreciate why PTFE is modified, we must first understand its baseline properties. It is a material of extremes, making it invaluable in some areas and unsuitable in others without enhancement.

The Unmatched Base Properties

Pure, or virgin PTFE, is renowned for a unique combination of characteristics. It is almost completely chemically inert, non-reactive to nearly all industrial chemicals and solvents.

It also boasts a very high melting point, maintains stability at extremely low temperatures, and has a famously low coefficient of friction, giving it a slippery, non-stick surface. Furthermore, its low electrical conductivity makes it an excellent insulator.

The Inherent Mechanical Limitations

Despite its strengths, virgin PTFE is a relatively soft material. It is prone to creep, or deformation under a sustained load, and has poor wear resistance when subjected to friction.

These mechanical shortcomings limit its use in applications that require high strength, rigidity, or durability against abrasive forces.

The Primary Modification: Compounding with Fillers

The most effective way to improve PTFE's mechanical performance is by blending it with reinforcing fillers. These materials are integrated into the PTFE matrix during processing, creating a composite material with superior properties.

How Fillers Enhance Performance

Fillers act as a reinforcing agent within the PTFE. They help bear loads, dissipate heat, and provide a harder surface that resists abrasion and deformation far better than the polymer alone.

The choice of filler is critical, as each one imparts a different set of properties to the final material.

Common Fillers and Their Impact

- Glass Fiber: This is one of the most common fillers. It significantly increases compressive strength and stiffness, reducing creep and improving wear resistance.

- Carbon and Graphite: Adding carbon or graphite dramatically improves wear resistance, load-bearing strength, and thermal conductivity. Carbon-filled grades are often self-lubricating, making them ideal for bearings.

- Bronze/Molybdenum Disulfide (Moly): This combination provides excellent compressive strength and high-load strength. The bronze also improves thermal conductivity, helping to dissipate frictional heat.

- Stainless Steel: Steel fillers are used to create grades with very high strength and load-bearing capabilities, often used in demanding process equipment.

- Ceramic: For applications requiring extreme wear and abrasion resistance, ceramic fillers provide one of the hardest and most durable PTFE compounds available.

Structural and Processing Modifications

Beyond fillers, PTFE can be modified through its physical form and processing methods to create materials suited for specific functions.

Expanded PTFE (ePTFE) for Sealing

By physically stretching PTFE under specific conditions, a microporous material called expanded PTFE (ePTFE) is created.

This material is exceptionally soft and conformable, making it an ideal gasket material that can seal rough or uneven surfaces under low bolt loads.

Dispersions and Powders for Surfaces

PTFE can be manufactured as a liquid dispersion or a fine micro powder. These forms are not used for solid components but are essential for creating coatings and additives.

Dispersions are used to create the non-stick coatings on cookware and industrial equipment. Micro powders are used as additives in other materials, such as lubricants and inks, to impart low-friction properties.

Understanding the Trade-offs

Modifying PTFE is not without compromise. Enhancing one property can sometimes slightly diminish another, and these trade-offs are critical to consider during material selection.

Impact on Chemical Resistance

While filled PTFE grades remain highly resistant to most chemicals, the addition of a filler can slightly reduce the absolute chemical inertness compared to 100% virgin PTFE. The filler material itself may be less resistant than the surrounding polymer.

Changes in Electrical Properties

Virgin PTFE is an outstanding electrical insulator. However, adding conductive fillers like carbon, graphite, or bronze will make the material electrically conductive, eliminating its use for insulation purposes.

The Cost of Performance

Generally, the more specialized the filler and the higher the performance of the modified compound, the higher the cost. Virgin PTFE is often the most economical choice when extreme mechanical properties are not required.

Matching the Right PTFE to Your Application

Choosing the correct grade of PTFE requires clearly defining your primary operational challenge.

- If your primary focus is extreme chemical inertness or electrical insulation: Virgin PTFE is the definitive and safest choice.

- If your primary focus is high-load or wear resistance in bearings: A carbon/graphite or bronze-filled grade is required.

- If your primary focus is sealing uneven or fragile flanges: Expanded PTFE (ePTFE) offers superior conformability and sealing performance.

- If your primary focus is strength and rigidity for structural parts: A glass-filled grade provides an excellent balance of properties and cost.

By understanding these modifications, you can leverage PTFE's unique benefits while overcoming its native limitations for virtually any demanding environment.

Summary Table:

| Filler Type | Key Performance Improvements | Ideal Applications |

|---|---|---|

| Glass Fiber | Increased compressive strength, stiffness, reduced creep | Structural parts, seals |

| Carbon/Graphite | Superior wear resistance, load-bearing, thermal conductivity | Bearings, high-wear components |

| Bronze/Moly | Excellent compressive & high-load strength, heat dissipation | High-load bearings, seals |

| Stainless Steel | Very high strength and load-bearing capability | Demanding process equipment |

| Ceramic | Extreme wear and abrasion resistance | Highly abrasive environments |

| ePTFE (Expanded) | Superior softness, conformability for sealing | Gaskets for uneven surfaces |

Need a PTFE component tailored to your exact requirements? At KINTEK, we specialize in precision manufacturing and custom fabrication of PTFE components—from seals and liners to complex labware. Whether you need the chemical resistance of virgin PTFE or the enhanced mechanical properties of a filled compound for semiconductor, medical, or industrial applications, we deliver solutions from prototypes to high-volume orders.

Contact our experts today to discuss how we can optimize PTFE for your specific needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support