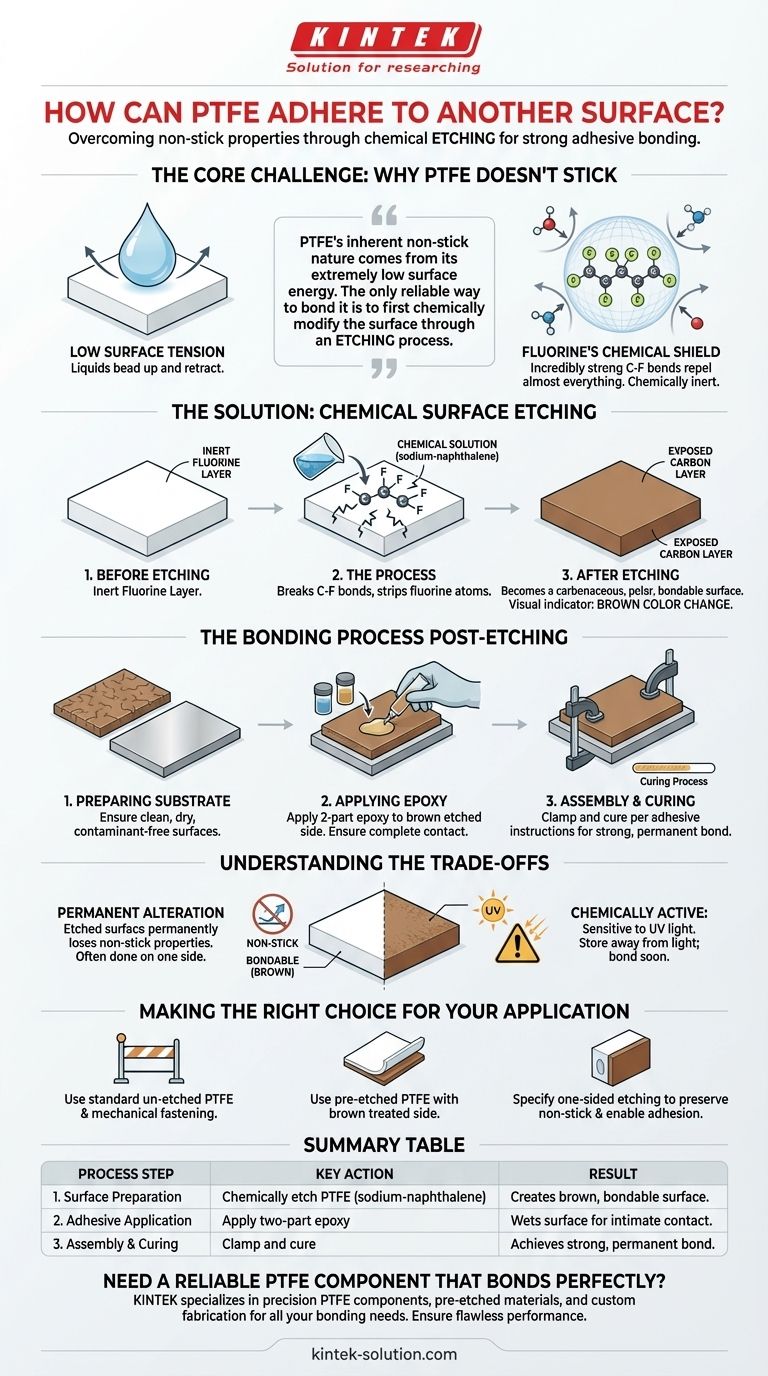

To make Polytetrafluoroethylene (PTFE) adhere to another surface, its famously non-stick properties must be overcome through a chemical process known as etching. This treatment alters the molecular structure of the PTFE surface, turning it a distinct brown color and making it receptive to bonding agents like epoxy, which can then create a strong, permanent bond with another material.

PTFE's inherent non-stick nature comes from its extremely low surface energy. The only reliable way to bond it using adhesives is to first chemically modify the surface through an etching process, which fundamentally changes its properties to allow adhesion.

The Core Challenge: Why PTFE Doesn't Stick

PTFE, commonly known by the brand name Teflon®, is one of the most slippery materials known. This property, while highly desirable for many applications, makes adhesive bonding seem impossible. The reasons are rooted in its fundamental chemistry.

The Problem of Low Surface Tension

For an adhesive to work, it must be able to "wet" a surface—that is, spread out and make intimate contact. PTFE has an extremely low surface tension, which causes liquids and adhesives to bead up and retract rather than spread.

This is the same principle that makes water bead on a freshly waxed car; the surface repels the liquid, preventing any real bond from forming.

Fluorine's Chemical Shield

At a molecular level, PTFE consists of a carbon chain completely surrounded by fluorine atoms. These carbon-fluorine bonds are incredibly strong and stable.

This "fluorine shield" is chemically inert and non-polar, meaning it has virtually no points of attraction for other molecules to latch onto. It effectively repels almost everything.

The Solution: Chemical Surface Etching

To bond PTFE, you cannot work with its natural surface; you must change it. Etching is the industry-standard chemical process designed to do exactly that.

What Is Etching?

Etching is a process where the PTFE material is exposed to a highly reactive chemical solution, typically a sodium-naphthalene complex.

This solution attacks the PTFE surface, breaking the powerful carbon-fluorine bonds and stripping away the fluorine atoms.

Creating a Bondable Surface

Once the fluorine atoms are removed, a layer of carbon atoms is left exposed. This de-fluorinated layer is no longer inert.

It becomes a carbonaceous, polar surface that is highly receptive to mechanical and chemical bonding with adhesives.

The Visual Indicator: A Color Change

A successfully etched PTFE surface is easy to identify. The chemical reaction turns the treated area from its typical white color to a uniform light or dark brown.

This color change serves as a crucial visual confirmation that the surface has been properly modified and is ready for bonding.

The Bonding Process Post-Etching

Once a PTFE surface is etched, it can be bonded using conventional industrial adhesives. The most common and effective choice is a two-part epoxy.

Preparing the Substrate

The etched PTFE surface, as well as the surface of the other material (e.g., metal, ceramic, or another plastic), should be clean, dry, and free of contaminants before applying the adhesive.

Applying the Epoxy

The epoxy is mixed and applied evenly to the brown, etched side of the PTFE. The part is then pressed firmly against the other substrate to ensure complete contact and a thin, uniform bond line.

The assembly is then clamped and cured according to the epoxy manufacturer's instructions to achieve maximum bond strength.

Understanding the Trade-offs

While etching is a powerful solution, it's essential to understand its implications. The process is not without important considerations.

Etching is a Permanent Alteration

The etching process is irreversible. The treated surface permanently loses its non-stick and low-friction properties.

For this reason, PTFE is often etched on only one side, allowing it to be bonded to a substrate while the other side maintains its characteristic slipperiness.

A Chemically Active Surface

The brown, etched surface is now chemically active and susceptible to degradation from UV light. It should be stored away from light and bonded relatively soon after treatment for the best results.

Keeping the surface clean and free from oils or dust before bonding is critical for achieving a reliable connection.

Making the Right Choice for Your Application

To successfully use PTFE in a bonded assembly, your approach must be intentional and align with the material's unique properties.

- If your primary focus is a simple non-stick barrier: Use standard, un-etched PTFE and rely on mechanical fastening (e.g., screws or a press-fit), as any adhesive will compromise its core property.

- If your primary focus is to bond a PTFE liner: You must source and use a pre-etched PTFE sheet or film, identifiable by its brown, treated side.

- If you are designing a custom component for bonding: Specify one-sided etching in your design to preserve the critical non-stick properties on the functional face while enabling adhesion on the back.

By understanding and leveraging chemical etching, you can successfully integrate the unique benefits of PTFE into assemblies that require a permanent, adhesive bond.

Summary Table:

| Process Step | Key Action | Result |

|---|---|---|

| 1. Surface Preparation | Chemically etch PTFE using a sodium-naphthalene solution. | Breaks carbon-fluorine bonds, creating a brown, bondable surface. |

| 2. Adhesive Application | Apply a two-part epoxy to the etched surface. | Epoxy wets the surface and makes intimate contact for bonding. |

| 3. Assembly & Curing | Clamp the assembly and cure according to epoxy instructions. | Achieves a strong, permanent bond with the substrate. |

Need a reliable PTFE component that bonds perfectly?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We provide pre-etched PTFE and custom fabrication services, from prototypes to high-volume orders, ensuring your bonded assemblies perform flawlessly.

Contact us today to discuss your project requirements and leverage our expertise in PTFE solutions!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the additional properties of PTFE? Beyond Non-Stick: Extreme Chemical, Thermal & Electrical Performance

- Is PTFE safe for use in electrical environments? Achieve Superior Insulation & Reliability

- What industries commonly use ePTFE? Discover Where This High-Performance Material Excels

- What forms is PTFE available in besides sheets and rods? Discover the Full Range of PTFE Options

- What are the key properties of PTFE plastic? Harness Extreme Chemical & Thermal Resistance

- Why is PTFE used as an electrical insulator? Unmatched Performance in Harsh Environments

- What are the limitations of PTFE as a material? Key Mechanical Weaknesses to Consider

- What are the thermal and electrical properties of PTFE? A Guide to Its Extreme Performance