In the electrical industry, PTFE is primarily used as a high-performance insulator and dielectric material. Its unique properties make it indispensable for wrapping wires and cables, manufacturing printed circuit boards (PCBs) for high-frequency applications, and fabricating critical components like connectors, capacitors, and semiconductor parts where reliability is non-negotiable.

The core reason PTFE is so prevalent in electronics is not just its ability to insulate, but its capacity to maintain exceptional electrical performance and signal integrity under extreme conditions—from high temperatures and corrosive chemicals to high-frequency signals where other materials would fail.

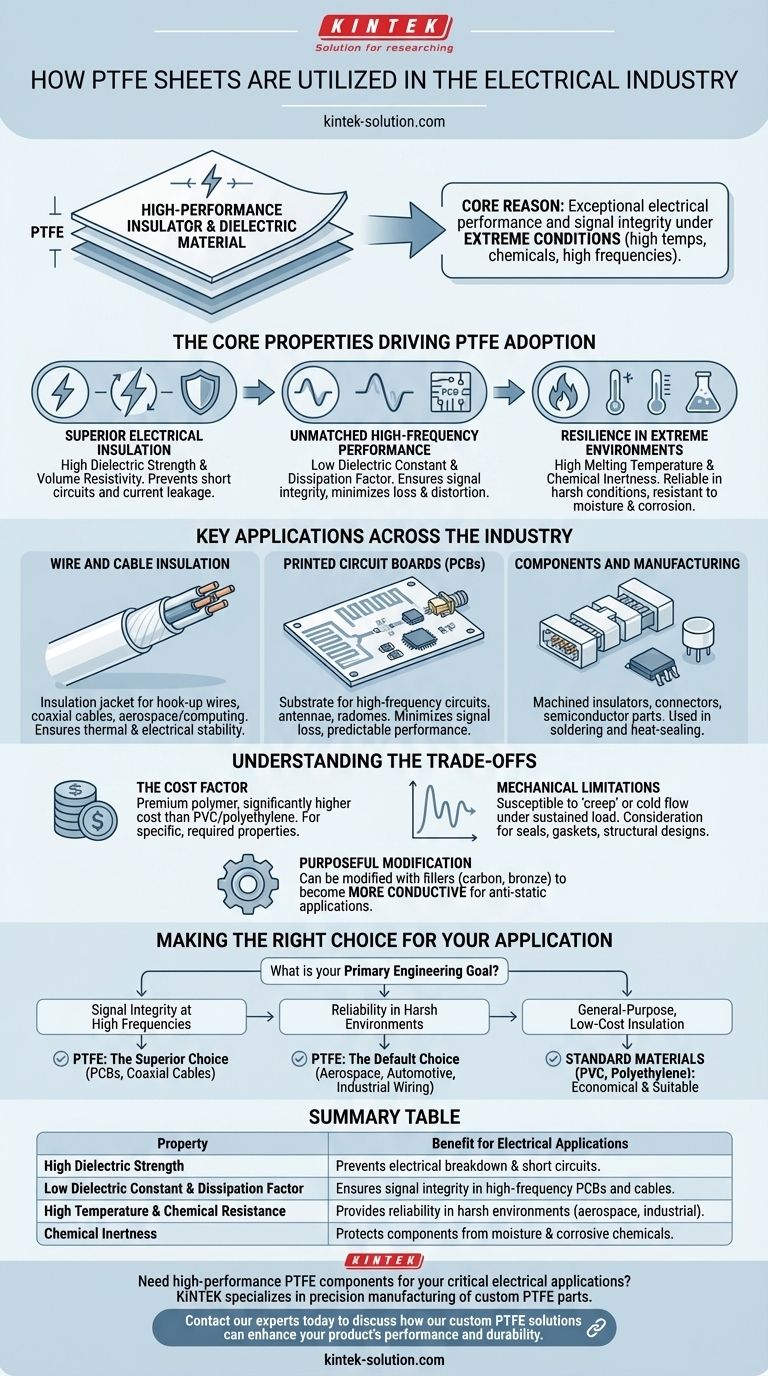

The Core Properties Driving PTFE Adoption

To understand why PTFE is so foundational in electronics, we must look beyond its general use and examine the specific electrical and physical properties that engineers depend on.

Superior Electrical Insulation

PTFE possesses an extremely high dielectric strength and high volume resistivity. In practical terms, this means it can withstand a very strong electric field without breaking down and is highly resistant to conducting electrical current.

This makes it an ideal material for preventing short circuits and current leakage in everything from simple hook-up wires to complex motor and transformer assemblies.

Unmatched High-Frequency Performance

For applications involving high-frequency signals, such as in coaxial cables, antennae, and advanced PCBs, two properties are critical: a low dielectric constant and a low dissipation factor.

PTFE excels at both. Its low dielectric constant ensures that it doesn't store significant electrical energy, which prevents signal distortion. Its low dissipation factor means it loses very little signal energy as heat, preserving the integrity and strength of the signal as it travels.

Resilience in Extreme Environments

Electrical components are often subjected to harsh operating conditions. PTFE offers elite protection due to its high melting temperature and its inherent chemical inertness.

It can operate reliably where other insulators would degrade or melt. Furthermore, it resists moisture and corrosive chemicals, protecting delicate wires and components from environmental damage and ensuring long-term stability.

Key Applications Across the Industry

PTFE's unique combination of properties makes it a high-performance substitute for materials like polyethylene, leading to its widespread use in demanding sectors. Nearly 50% of all PTFE produced is for wiring in aerospace and computer applications.

Wire and Cable Insulation

This is PTFE's most common electrical application. It is used as an insulation jacket for hook-up wires, coaxial cables, and other wiring in aerospace, computing, and industrial machinery. Its thermal and electrical stability ensures signals are transmitted reliably and safely.

Printed Circuit Boards (PCBs)

In high-frequency electronics, the PCB substrate material is as important as the components on it. PTFE is used as a substrate for circuits in antennae, radomes, and other radio frequency (RF) systems because it minimizes signal loss and ensures predictable performance.

Components and Manufacturing

PTFE's non-reactive and heat-resistant nature makes it valuable in the manufacturing process itself, used in soldering and heat-sealing applications to protect components.

It is also machined into essential parts like insulators, connector assemblies, semiconductor parts, and even specialized components for sensors and microphones.

Understanding the Trade-offs

While its performance is exceptional, PTFE is not the default choice for every application. Its selection involves clear engineering trade-offs.

The Cost Factor

PTFE is a premium, high-performance polymer. Its cost is significantly higher than that of common insulators like polyethylene or PVC. Its use is typically reserved for applications where its specific properties are a strict requirement, not a preference.

Mechanical Limitations

While durable, PTFE can be susceptible to "creep" or cold flow, meaning it can deform over time when subjected to a sustained compressive load. This must be a consideration in mechanical designs for seals, gaskets, and structural insulators.

Purposeful Modification

Interestingly, while PTFE is a premier insulator, it can be modified. By adding fillers such as carbon or bronze, its properties can be altered to become more conductive. This is useful for creating anti-static components where you need to dissipate static charge safely rather than insulate against it completely.

Making the Right Choice for Your Application

Selecting the right material requires a clear understanding of your primary engineering goal.

- If your primary focus is signal integrity at high frequencies: PTFE is the superior choice for PCBs and coaxial cables due to its low dielectric constant and low loss factor.

- If your primary focus is reliability in harsh environments: PTFE's thermal stability and chemical resistance make it the default for critical aerospace, automotive, and industrial wiring.

- If your primary focus is general-purpose, low-cost insulation: A standard material like PVC or polyethylene is often a more economical and perfectly suitable solution.

Ultimately, selecting PTFE is a strategic decision to prioritize long-term reliability and signal performance in the most demanding electrical systems.

Summary Table:

| Property | Benefit for Electrical Applications |

|---|---|

| High Dielectric Strength | Prevents electrical breakdown and short circuits. |

| Low Dielectric Constant & Dissipation Factor | Ensures signal integrity in high-frequency PCBs and cables. |

| High Temperature & Chemical Resistance | Provides reliability in harsh environments (aerospace, industrial). |

| Chemical Inertness | Protects components from moisture and corrosive chemicals. |

Need high-performance PTFE components for your critical electrical applications?

KINTEK specializes in the precision manufacturing of PTFE parts—including custom sheets, seals, insulators, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We ensure the material properties you rely on for signal integrity and reliability are met with every order, from prototypes to high-volume production.

Contact our experts today to discuss how our custom PTFE solutions can enhance your product's performance and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications