In the chemical and pharmaceutical sectors, PTFE guide strips are primarily used as critical sealing and guiding components inside equipment that must withstand highly corrosive substances and maintain absolute product purity. They function as robust seals, low-friction piston or rod guides, and chemically inert gaskets where material failure would lead to catastrophic equipment damage or product contamination.

The core challenge in the chemical and pharmaceutical industries is not just moving fluids or machine parts, but doing so without the equipment degrading or the product being contaminated. PTFE guide strips solve this by providing a chemically inert, low-friction barrier that simultaneously protects mechanical components and preserves the purity of the end product.

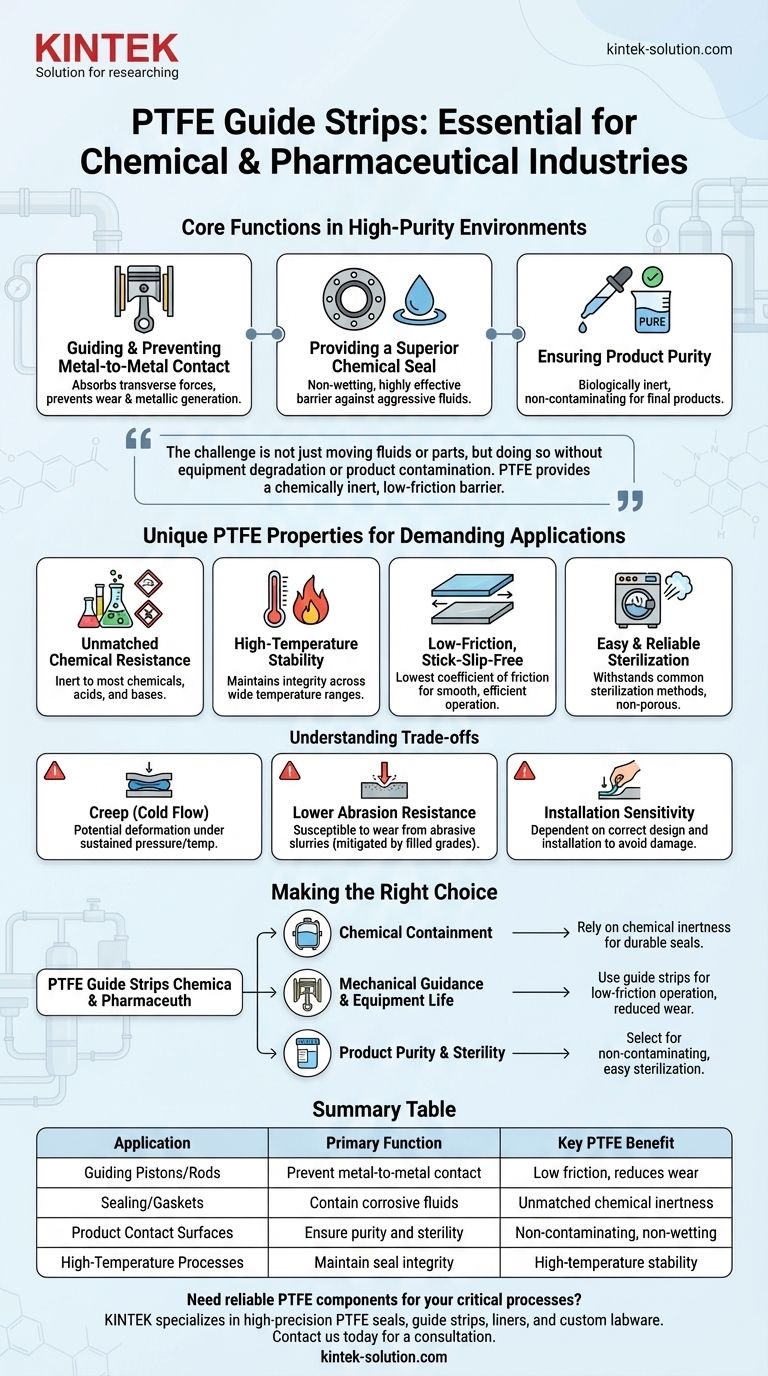

The Core Functions of PTFE in High-Purity Environments

PTFE's value extends beyond a single feature. It serves several distinct but related functions that are essential for reliable operation in demanding chemical and pharmaceutical processing.

Guiding and Preventing Metal-to-Metal Contact

PTFE guide strips are installed on pistons and rods within hydraulic and pneumatic cylinders. Their primary role here is to absorb transverse forces and guide the moving components accurately.

This prevents metal-to-metal contact between the piston/rod and the cylinder bore. This single function drastically reduces wear and deterioration, extending the life of expensive equipment and preventing the generation of metallic particulates.

Providing a Superior Chemical Seal

When used as gaskets, O-rings, or cap liners, PTFE creates a highly effective seal. Its unique properties make it ideal for containing aggressive fluids that would quickly degrade other materials.

Because PTFE is non-wetting (hydrophobic), liquids bead up on its surface instead of spreading. This property enhances its sealing capability, providing better protection against the microscopic leaks that can occur with other elastomers.

Ensuring Product Purity

In pharmaceutical manufacturing, preventing contamination is the highest priority. PTFE is inherently non-contaminating and biologically inert.

It does not react with, leach into, or absorb the chemicals or drug products it contacts. This ensures the final product remains pure and meets stringent regulatory standards.

Why PTFE is Uniquely Suited for These Demands

Several key material properties make PTFE the default choice for these critical applications. Understanding these properties reveals why it consistently outperforms other polymers.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, acids, and bases. This makes it an ideal material for components in chemical reactors, pumps, valves, and tubing that handle highly corrosive substances.

High-Temperature Stability

Chemical and pharmaceutical processes often involve extreme temperatures. PTFE maintains its integrity and performance characteristics across a very wide temperature range, ensuring reliable operation where other materials would fail.

Low-Friction, Stick-Slip-Free Operation

PTFE has one of the lowest coefficients of friction of any solid material. This results in smooth, stick-slip-free operation of moving parts.

This low-friction movement reduces the energy required to operate equipment, minimizes heat generation, and ensures precise, repeatable mechanical action.

Easy and Reliable Sterilization

For pharmaceutical and medical applications, components must be easily sterilized. PTFE's non-porous surface and high-temperature resistance allow it to withstand common sterilization methods, like autoclaving, without degrading.

Understanding the Trade-offs

While exceptionally capable, PTFE is not without its limitations. Acknowledging these trade-offs is key to proper application engineering.

Susceptibility to Creep (Cold Flow)

Under sustained pressure and temperature, PTFE can slowly deform over time, a phenomenon known as creep or cold flow. In high-pressure sealing applications, this must be accounted for in the design to prevent seal failure.

Lower Abrasion Resistance

Compared to harder plastics, pure PTFE can be more susceptible to wear from abrasive slurries or rough mating surfaces. This is often mitigated by using filled grades of PTFE, where materials like glass, carbon, or bronze are added to improve mechanical strength and wear resistance.

Installation Sensitivity

The effectiveness of a PTFE guide strip or seal is highly dependent on correct design and installation. Improper sizing or sharp edges in the hardware can cause the strip to be shaved or damaged during assembly, compromising its function.

Making the Right Choice for Your Application

To apply PTFE effectively, align your material choice with your primary operational goal.

- If your primary focus is chemical containment: Rely on PTFE's unparalleled chemical inertness to create durable seals and gaskets for handling aggressive acids, solvents, and bases.

- If your primary focus is mechanical guidance and equipment life: Use PTFE guide strips to prevent metal-to-metal contact in hydraulic or pneumatic systems, ensuring low-friction operation and reduced wear.

- If your primary focus is product purity and sterility: Select PTFE for any component contacting the final product, leveraging its non-contaminating, non-wetting, and easily sterilized nature.

Choosing the right material is a foundational decision that ensures the safety, reliability, and integrity of your entire process.

Summary Table:

| Application | Primary Function | Key PTFE Benefit |

|---|---|---|

| Guiding Pistons/Rods | Prevent metal-to-metal contact | Low friction, reduces wear |

| Sealing/Gaskets | Contain corrosive fluids | Unmatched chemical inertness |

| Product Contact Surfaces | Ensure purity and sterility | Non-contaminating, non-wetting |

| High-Temperature Processes | Maintain seal integrity | High-temperature stability |

Need reliable PTFE components for your critical processes?

At KINTEK, we specialize in manufacturing high-precision PTFE seals, guide strips, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment operates with maximum chemical resistance, product purity, and longevity.

We offer custom fabrication from prototypes to high-volume orders, tailored to your specific requirements. Let's discuss how our PTFE solutions can enhance the safety and efficiency of your operations.

Contact us today for a consultation

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application