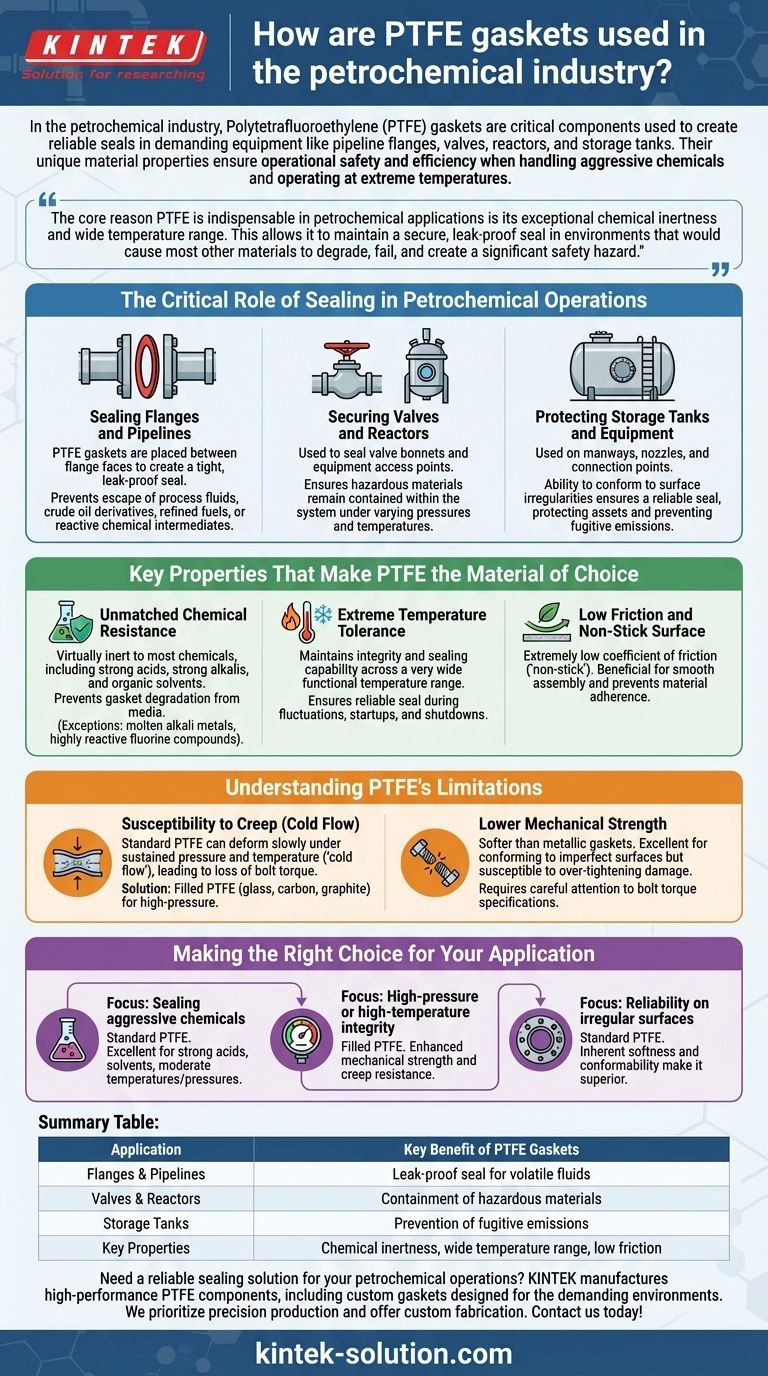

In the petrochemical industry, Polytetrafluoroethylene (PTFE) gaskets are critical components used to create reliable seals in demanding equipment like pipeline flanges, valves, reactors, and storage tanks. They are specified for these applications because their unique material properties ensure operational safety and efficiency when handling aggressive chemicals and operating at extreme temperatures.

The core reason PTFE is indispensable in petrochemical applications is its exceptional chemical inertness and wide temperature range. This allows it to maintain a secure, leak-proof seal in environments that would cause most other materials to degrade, fail, and create a significant safety hazard.

The Critical Role of Sealing in Petrochemical Operations

In any refinery or chemical processing plant, the primary goal is to contain and control volatile, corrosive, and often hazardous materials. A gasket's failure is not an inconvenience; it can be a catastrophic event leading to leaks, environmental damage, and safety risks.

Sealing Flanges and Pipelines

A petrochemical facility is a vast network of interconnected pipes. PTFE gaskets are placed between flange faces—the connecting points in this network—to create a tight, leak-proof seal.

This prevents the escape of process fluids, whether they are crude oil derivatives, refined fuels, or reactive chemical intermediates.

Securing Valves and Reactors

Valves control the flow of materials, and reactors contain chemical processes. Both operate under varying pressures and temperatures.

PTFE gaskets are used to seal valve bonnets and equipment access points, ensuring that hazardous materials remain contained within the system.

Protecting Storage Tanks and Equipment

Large tanks store raw materials and finished products. PTFE gaskets are used on manways, nozzles, and other connection points.

Their ability to conform to surface irregularities ensures a reliable seal, protecting valuable assets and preventing fugitive emissions.

Key Properties That Make PTFE the Material of Choice

Not all sealing materials can withstand the rigors of the petrochemical industry. PTFE's unique combination of properties makes it a default choice for many engineers.

Unmatched Chemical Resistance

PTFE is virtually inert to most chemicals, including strong acids, strong alkalis, and organic solvents.

This property is essential for preventing the gasket material itself from degrading or reacting with the media it is sealing. The only common exceptions are molten alkali metals and highly reactive fluorine compounds.

Extreme Temperature Tolerance

Petrochemical processes can involve extreme heat and cryogenic cold. PTFE gaskets maintain their integrity and sealing capability across a very wide functional temperature range.

This thermal stability ensures a reliable seal during temperature fluctuations, startups, and shutdowns.

Low Friction and Non-Stick Surface

PTFE has an extremely low coefficient of friction, often referred to as a "non-stick" surface.

This property is beneficial during assembly, as it allows for a smooth and even compression of the gasket. It also prevents material from the process media from adhering to the gasket surface.

Understanding PTFE's Limitations

While highly effective, no material is perfect. Acknowledging the trade-offs is crucial for proper engineering and application.

Susceptibility to Creep (Cold Flow)

Standard, unfilled PTFE can be prone to creep, or "cold flow," under sustained pressure and temperature. This is a slow deformation of the material that can lead to a loss of bolt torque and sealing pressure over time.

For high-pressure applications, engineers often specify filled PTFE gaskets, which incorporate materials like glass, carbon, or graphite to enhance creep resistance and mechanical strength.

Lower Mechanical Strength

Compared to metallic or semi-metallic gaskets, PTFE is a softer material. This makes it excellent for conforming to imperfect flange surfaces but also makes it more susceptible to damage from over-tightening or improper installation.

Careful attention to bolt torque specifications is essential to avoid crushing the gasket and compromising the seal.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching the material's properties to the operational demands.

- If your primary focus is sealing aggressive chemicals: Standard PTFE is an excellent choice for applications involving strong acids, solvents, or other corrosive media where temperatures and pressures are moderate.

- If your primary focus is high-pressure or high-temperature integrity: Consider a filled PTFE gasket, which provides enhanced mechanical strength and significantly better resistance to creep.

- If your primary focus is reliability on irregular surfaces: The inherent softness and conformability of PTFE make it a superior choice for creating a seal on flanges that may have minor scratches or imperfections.

Ultimately, specifying PTFE gaskets is a strategic decision to ensure the safety, reliability, and efficiency of critical petrochemical operations.

Summary Table:

| Application | Key Benefit of PTFE Gaskets |

|---|---|

| Flanges & Pipelines | Leak-proof seal for volatile fluids |

| Valves & Reactors | Containment of hazardous materials |

| Storage Tanks | Prevention of fugitive emissions |

| Key Properties | Chemical inertness, wide temperature range, low friction |

Need a reliable sealing solution for your petrochemical operations? KINTEK manufactures high-performance PTFE components, including custom gaskets designed for the demanding environments of the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders. Contact us today to discuss how our PTFE seals can enhance the safety and efficiency of your equipment!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance