In essence, PTFE bellow seals are exceptionally resistant to environmental factors. Their unique molecular structure makes them one of the most stable and inert materials used in industrial sealing, demonstrating remarkable resilience against aggressive chemicals, extreme temperatures, high pressures, and electrical stresses.

The core takeaway is that PTFE bellow seals are a default solution for the most demanding environments due to their near-universal chemical inertness and wide operational range. Understanding their few, very specific limitations is the key to deploying them successfully.

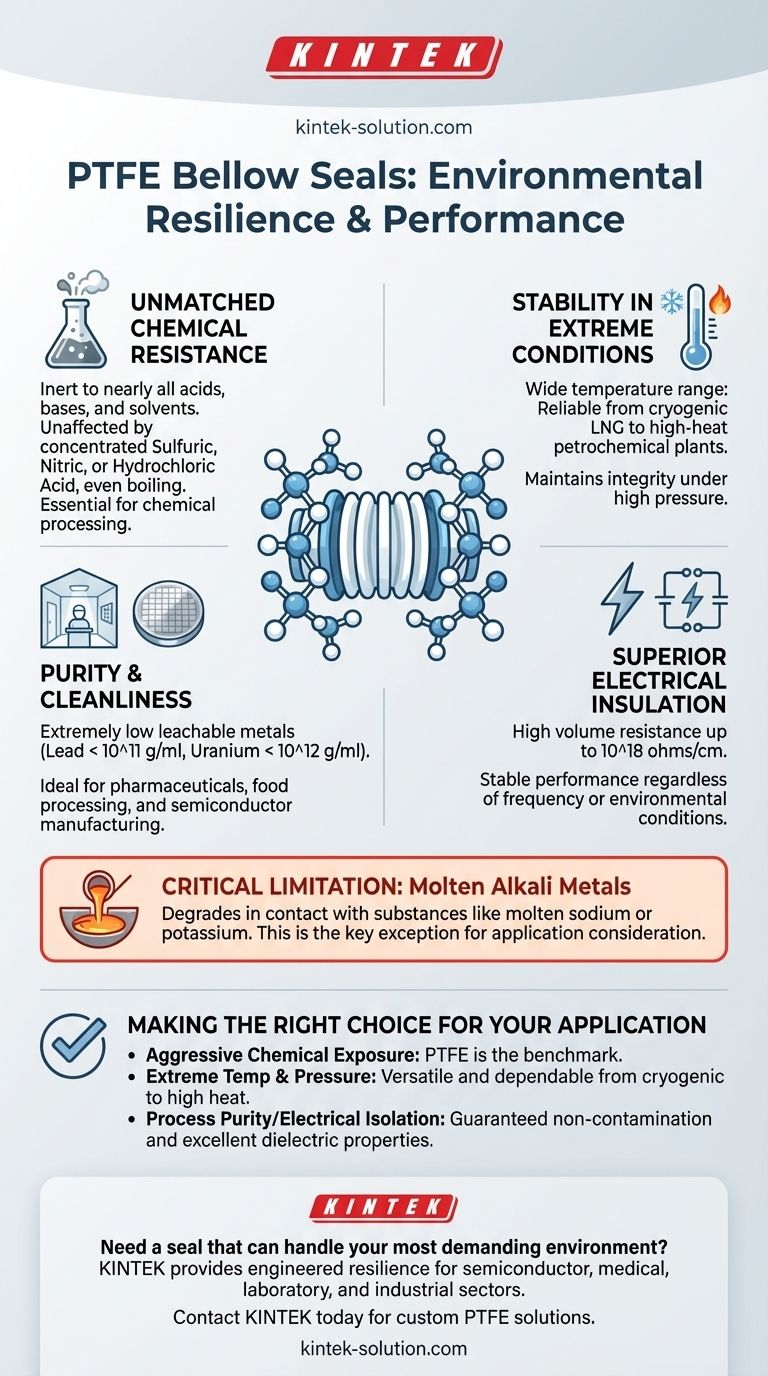

Unmatched Chemical and Environmental Resistance

Polytetrafluoroethylene (PTFE) is engineered for stability. Its performance is fundamentally tied to its inherent molecular properties, which make it non-reactive in situations where other materials would quickly degrade.

Inertness to Aggressive Chemicals

PTFE bellow seals are not corroded by almost any chemical reagent.

They remain entirely unaffected by highly corrosive substances like concentrated sulfuric acid, nitric acid, or hydrochloric acid, even under boiling conditions. This makes them indispensable in chemical processing and manufacturing.

Purity for Contamination-Sensitive Processes

The material maintains extremely low levels of leachable metals.

With lead content below 10^-11 g/ml and uranium below 10^-12 g/ml, PTFE seals are ideal for high-purity applications in pharmaceuticals, food processing, and semiconductor manufacturing where process contamination cannot be tolerated.

Performance Across Extreme Physical Conditions

Beyond chemical stability, PTFE seals maintain their integrity across a vast spectrum of physical operating conditions, from cryogenic lows to high-temperature, high-pressure industrial processes.

Stability in Wide Temperature Ranges

PTFE seals operate reliably across an exceptionally wide temperature range.

They provide consistent performance in high-temperature environments like petrochemical plants and maintain their flexibility and sealing capability in low-temperature systems, such as those used for liquefied natural gas (LNG).

Integrity Under Pressure

These seals continue to function effectively without leaking when exposed to pressurized fluids or gases. Their design ensures a reliable barrier between mating surfaces, preventing system failure.

Superior Electrical Insulation

PTFE is an outstanding electrical insulator, a property that remains stable regardless of environmental conditions or frequency.

It features a high volume resistance of up to 10^18 ohms/cm, a small dielectric loss, and a high breakdown voltage, making it suitable for applications where electrical isolation is critical.

Understanding the Critical Limitations

While PTFE is remarkably resilient, no material is without limitations. Its primary weakness is highly specific and only relevant in a narrow set of industrial applications.

The Key Exception: Molten Alkali Metals

The only common chemical class that can attack PTFE is molten alkali metals.

In environments where substances like molten sodium or potassium are present, PTFE will degrade. This is a well-defined limitation that must be considered during material selection for these specific processes.

Making the Right Choice for Your Application

Selecting a seal requires matching its material properties to the specific challenges of your operating environment. PTFE's profile makes it a straightforward choice for many severe-service applications.

- If your primary focus is aggressive chemical exposure: PTFE is the benchmark for chemical inertness, providing a reliable seal against nearly all acids, bases, and solvents.

- If your primary focus is extreme temperature or pressure: PTFE's ability to perform consistently from cryogenic temperatures to high-heat industrial processes makes it a versatile and dependable choice.

- If your primary focus is process purity or electrical isolation: The material's inherent cleanliness and excellent dielectric properties ensure it will not contaminate the process fluid or interfere with electrical systems.

Ultimately, for nearly any environment short of contact with molten alkali metals, a PTFE bellow seal provides a robust and reliable sealing solution.

Summary Table:

| Environmental Factor | PTFE Bellow Seal Performance | Key Limitation |

|---|---|---|

| Chemical Resistance | Inert to nearly all acids, bases, and solvents (e.g., sulfuric acid). | Degrades in contact with molten alkali metals. |

| Temperature Range | Stable from cryogenic (LNG) to high-temperature processes. | N/A for standard chemical environments. |

| Pressure & Mechanical Integrity | Maintains seal integrity under high pressure. | N/A for standard chemical environments. |

| Purity & Electrical Insulation | Extremely low leachables; high dielectric strength (up to 10^18 ohms/cm). | N/A for standard chemical environments. |

Need a seal that can handle your most demanding environment?

PTFE bellow seals from KINTEK are engineered for resilience. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our seals provide the critical protection you need:

- Unmatched Chemical Inertness: Confidently seal against aggressive acids, bases, and solvents.

- Extreme Temperature & Pressure Stability: Ensure reliable performance from cryogenic applications to high-heat processes.

- Guaranteed Purity: Protect sensitive processes in pharmaceuticals and semiconductor manufacturing with ultra-low leachable components.

We specialize in custom fabrication, from prototypes to high-volume orders, ensuring a perfect fit for your specific application.

Contact KINTEK today to discuss your sealing challenges and discover the right PTFE solution for you.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance

- What are PTFE seals and why are they considered a reliable solution for extreme environments? Engineered for Harsh Conditions

- How do PTFE seals perform under pressurized conditions? Achieving Reliable Sealing in Demanding Environments

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance