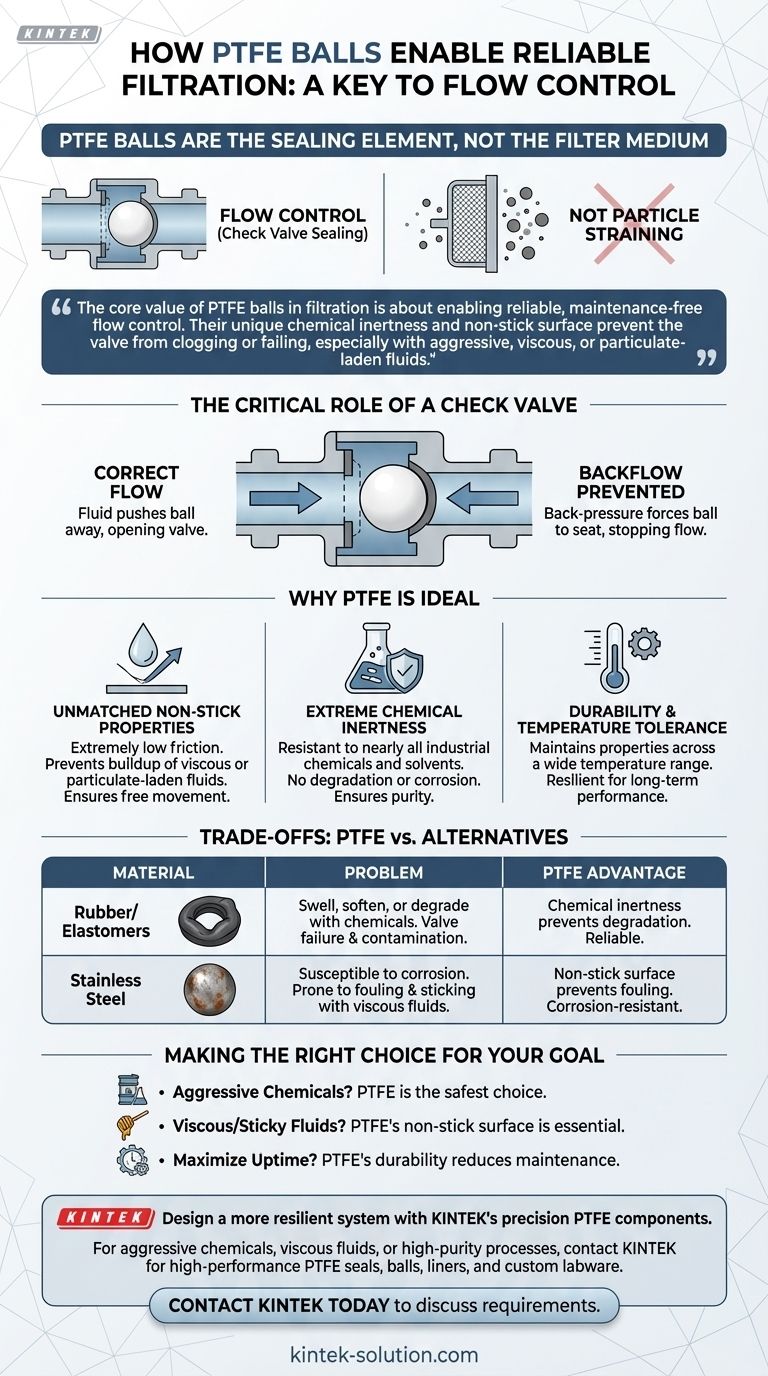

In filtering applications, PTFE balls are typically not the filter medium itself. Instead, they serve as a critical component for controlling fluid movement, most often functioning as the sealing element in a check valve. Their purpose is to ensure fluid flows in only one direction, preventing backflow and maintaining system integrity.

The core value of PTFE balls in filtration is not about straining particles, but about enabling reliable, maintenance-free flow control. Their unique chemical inertness and non-stick surface prevent the valve from clogging or failing, especially when processing aggressive, viscous, or particulate-laden fluids.

The Critical Role of a Check Valve in Filtration

What is a Check Valve?

A check valve is a simple device that allows fluid to flow through it in only one direction. In many filtration systems, maintaining a consistent flow direction is essential for performance and to prevent contamination of upstream processes.

How the PTFE Ball Functions

The PTFE ball sits inside the valve body. When fluid flows in the correct direction, it pushes the ball away from its seat, opening the valve. If the flow stops or attempts to reverse, back-pressure forces the ball back onto the seat, creating a seal and stopping the backflow.

Why PTFE is the Ideal Material for this Role

Unmatched Non-Stick Properties

The defining feature of PTFE (Teflon) is its extremely low coefficient of friction. This non-stick surface is critical when filtering sticky, viscous, or particulate-heavy liquids.

Substances do not adhere to the ball, preventing the buildup that causes other materials to clog or fail. This ensures the ball can move freely and seal effectively every time.

Extreme Chemical Inertness

PTFE is resistant to nearly all industrial chemicals and solvents. This makes it the default choice for applications in chemical processing, pharmaceuticals, and food manufacturing.

The material will not degrade, corrode, or leach contaminants into the fluid, ensuring the purity of the filtered product and the longevity of the valve.

Durability and Temperature Tolerance

PTFE maintains its properties across a wide range of temperatures. It doesn't become brittle or soft, ensuring reliable performance in demanding environments. This durability means the valve will function efficiently over long periods without needing frequent replacement.

Understanding the Trade-offs: PTFE vs. Alternatives

The Problem with Rubber or Elastomers

While flexible, rubber-based materials can swell, soften, or degrade when exposed to aggressive chemicals or solvents. This leads to valve failure and potential contamination of the process fluid.

The Limitation of Stainless Steel

Although strong, stainless steel balls can be susceptible to corrosion from certain acids or chlorides. More importantly, they lack PTFE's non-stick properties, making them prone to fouling and sticking when used with viscous or particulate-laden fluids.

The PTFE Advantage

PTFE overcomes the primary failure points of both rubber and steel. Its combination of chemical inertness and a non-stick surface leads to higher reliability, less frequent maintenance, and broader application compatibility.

Making the Right Choice for Your Goal

- If your primary focus is filtering aggressive chemicals: PTFE is the safest and most reliable choice to prevent material degradation and ensure system longevity.

- If your primary focus is processing viscous or sticky fluids: PTFE's non-stick surface is essential for preventing valve clogging and ensuring consistent flow.

- If your primary focus is maximizing uptime and minimizing maintenance: The durability and anti-fouling nature of PTFE balls make them superior for long-term, trouble-free operation.

By understanding PTFE's role as a flow control mechanism, you can design more resilient and efficient filtration systems built to handle challenging conditions.

Summary Table:

| Feature | PTFE Ball Advantage |

|---|---|

| Primary Function | Sealing element in a check valve for one-way flow control |

| Key Benefit | Prevents backflow and maintains system integrity |

| Chemical Resistance | Inert to nearly all industrial chemicals and solvents |

| Non-Stick Surface | Prevents clogging from viscous or particulate-laden fluids |

| Durability | Long-lasting performance across a wide temperature range |

Design a more resilient and efficient filtration system with KINTEK's precision PTFE components.

When your application demands reliable flow control for aggressive chemicals, viscous fluids, or high-purity processes, the right PTFE component is critical. KINTEK specializes in manufacturing high-performance PTFE seals, balls, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications. Ensure your system's integrity and minimize downtime—let our expertise in PTFE solutions work for you.

Contact KINTEK today to discuss your project requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the advantages of using PTFE bushings in rotary motion applications? Achieve Zero-Maintenance, High-Performance Rotation

- How should PTFE material be supported during machining? Achieve Precision with Minimal Clamping Pressure

- What is expanded PTFE (ePTFE) and what are its key characteristics? Unlock Superior Sealing and Flexibility

- What are some tips for successful Teflon machining? Master Precision Cuts for PTFE Components

- What makes PTFE seals suitable for extreme temperature applications? Unmatched Stability from -200°C to +260°C

- What is the function of PTFE machined bellows? A Guide to Protecting Critical Systems

- What are the properties of Modified Polytetrafluoroethylene? Enhanced Performance for Demanding Applications

- What are the main machining techniques used for PTFE? Achieve Precision with CNC Turning, Milling & More