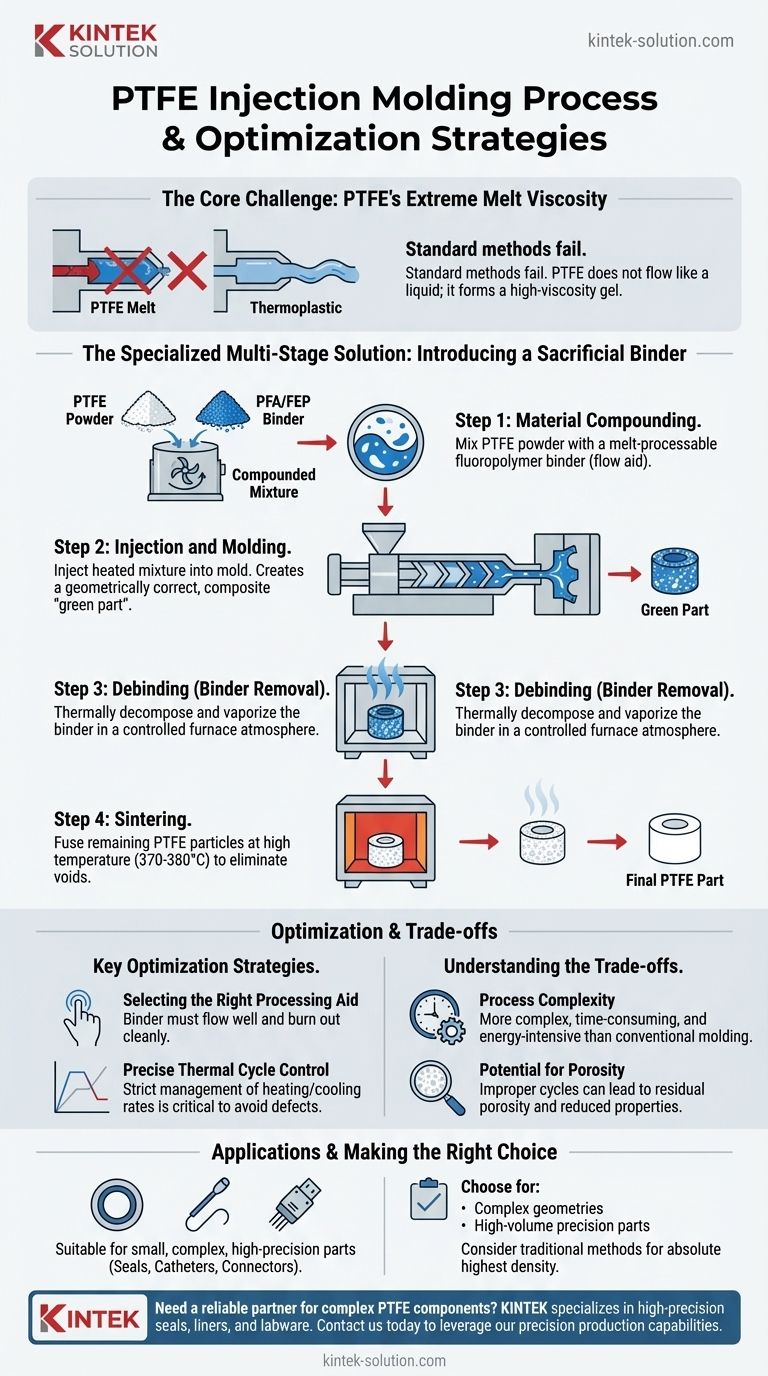

To be clear, PTFE (Polytetrafluoroethylene) cannot be injection molded using conventional thermoplastic methods due to its extremely high melt viscosity. Instead, a specialized multi-stage process akin to metal injection molding is used. This involves mixing fine PTFE powder with a melt-processable fluoropolymer binder (like PFA or FEP) to act as a flow aid, injecting this mixture into a mold, and then using a thermal process to first remove the binder and then sinter the remaining PTFE particles into a solid part.

The core challenge of molding PTFE is its refusal to flow like a typical liquid when melted. The solution is to temporarily introduce a processing aid that allows the material to fill a mold, which is then carefully removed in a subsequent high-temperature process, leaving behind a pure, densified PTFE component.

Why Standard Injection Molding Fails with PTFE

The Problem of Extreme Melt Viscosity

Unlike common thermoplastics like Polypropylene or Polycarbonate, PTFE does not transition to a low-viscosity, easily flowable liquid above its melting point. Instead, it forms a transparent, high-viscosity gel.

This viscosity is so high—millions of times higher than typical thermoplastics—that it cannot be forced through the nozzle, runner, and gate systems of a standard injection molding machine.

The Need for a Modified Approach

Because PTFE won't flow, a carrier material is required to transport the PTFE particles into the mold cavity. This fundamental difference necessitates the specialized, multi-step process detailed below.

The PTFE Injection Molding Process: A Step-by-Step Guide

Step 1: Material Compounding

The process begins by mixing fine-grain PTFE powder with a powdered, melt-processable fluoropolymer, most commonly PFA (Perfluoroalkoxy alkane) or FEP (Fluorinated ethylene propylene).

This second polymer acts as a sacrificial processing aid or binder. Its purpose is to melt and carry the solid PTFE particles, creating a slurry that can flow under pressure.

Step 2: Injection and Molding

This compounded mixture is then heated in an injection molding machine to a temperature above the melting point of the binder (PFA/FEP), but below the degradation temperature of PTFE.

The machine injects the now-fluid mixture into a precision mold cavity. The result of this stage is a "green part" that is geometrically correct but is a composite of PTFE and the binder.

Step 3: Debinding (Binder Removal)

The green part is carefully ejected from the mold and placed into a high-temperature furnace with a precisely controlled atmosphere.

The temperature is slowly raised to a point where the binder (PFA or FEP) is thermally decomposed and vaporized, leaving the furnace as an exhaust gas. This must be done slowly to prevent the part from cracking or blistering.

Step 4: Sintering

After the debinding stage is complete, the furnace temperature is raised further, to just above the melting point of PTFE (around 370-380°C).

The part, now consisting only of loosely connected PTFE particles, is held at this temperature. The particles fuse together, voids are eliminated, and the material densifies into a solid, coherent component. This is the final, functional PTFE part.

Key Optimization Strategies

Selecting the Right Processing Aid

The choice of binder is critical. It must provide excellent flow during molding but also burn out cleanly during debinding without leaving a residue that could compromise the final PTFE properties. The binder's particle size and melt characteristics must be compatible with the PTFE grade being used.

Precise Thermal Cycle Control

This is the most critical variable for success. The heating and cooling rates during both debinding and sintering must be strictly managed. Ramping the temperature too quickly will cause defects, while improper sintering temperatures will result in a weak, porous part.

Understanding the Trade-offs

Process Complexity

This multi-stage process is significantly more complex, time-consuming, and energy-intensive than conventional injection molding. It requires specialized equipment and deep process expertise.

Potential for Porosity

If the debinding and sintering cycles are not perfectly optimized, the final part can have residual porosity. This can negatively affect its mechanical properties, dielectric strength, and permeability compared to parts made via compression molding.

Suitable Applications

This method is primarily used for producing small, complex, and high-precision PTFE parts that would be difficult or impossible to machine from stock material. Common examples include seals, medical catheters, and electronic insulators or connectors.

Making the Right Choice for Your Application

The decision to use PTFE injection molding depends entirely on the part's geometry and production volume requirements.

- If your primary focus is complex, small geometries: This process is an excellent choice for producing intricate net-shape parts that minimize or eliminate the need for secondary machining.

- If your primary focus is high-volume production of precision parts: For the right component, this method offers greater repeatability and scalability than machining individual parts from rod or sheet stock.

- If your primary focus is achieving the absolute highest material density and performance: Traditional methods like compression molding followed by machining should be considered, as they avoid the complexities and potential pitfalls of the binder burnout process.

Ultimately, this specialized process bridges a critical manufacturing gap, enabling the creation of complex PTFE components where no other method is viable.

Summary Table:

| Process Stage | Key Action | Critical Consideration |

|---|---|---|

| Compounding | Mix PTFE powder with PFA/FEP binder | Binder selection for flow and clean burnout |

| Injection Molding | Inject heated mixture into mold | Temperature control to avoid PTFE degradation |

| Debinding | Thermally remove binder in furnace | Slow ramp rates to prevent part defects |

| Sintering | Fuse PTFE particles at high temperature | Precise temperature for optimal density |

Need a reliable partner for complex PTFE components? KINTEK specializes in manufacturing high-precision PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your parts meet exact specifications with superior material performance. Contact us today to discuss your project and leverage our precision production capabilities.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments