Yes, absolutely. Polytetrafluoroethylene (PTFE) machined parts are not only customizable, but they are frequently designed and fabricated to meet highly specific and demanding requirements. This customization extends to virtually any size, shape, or complex geometry your application requires, from simple washers to intricate components for advanced equipment.

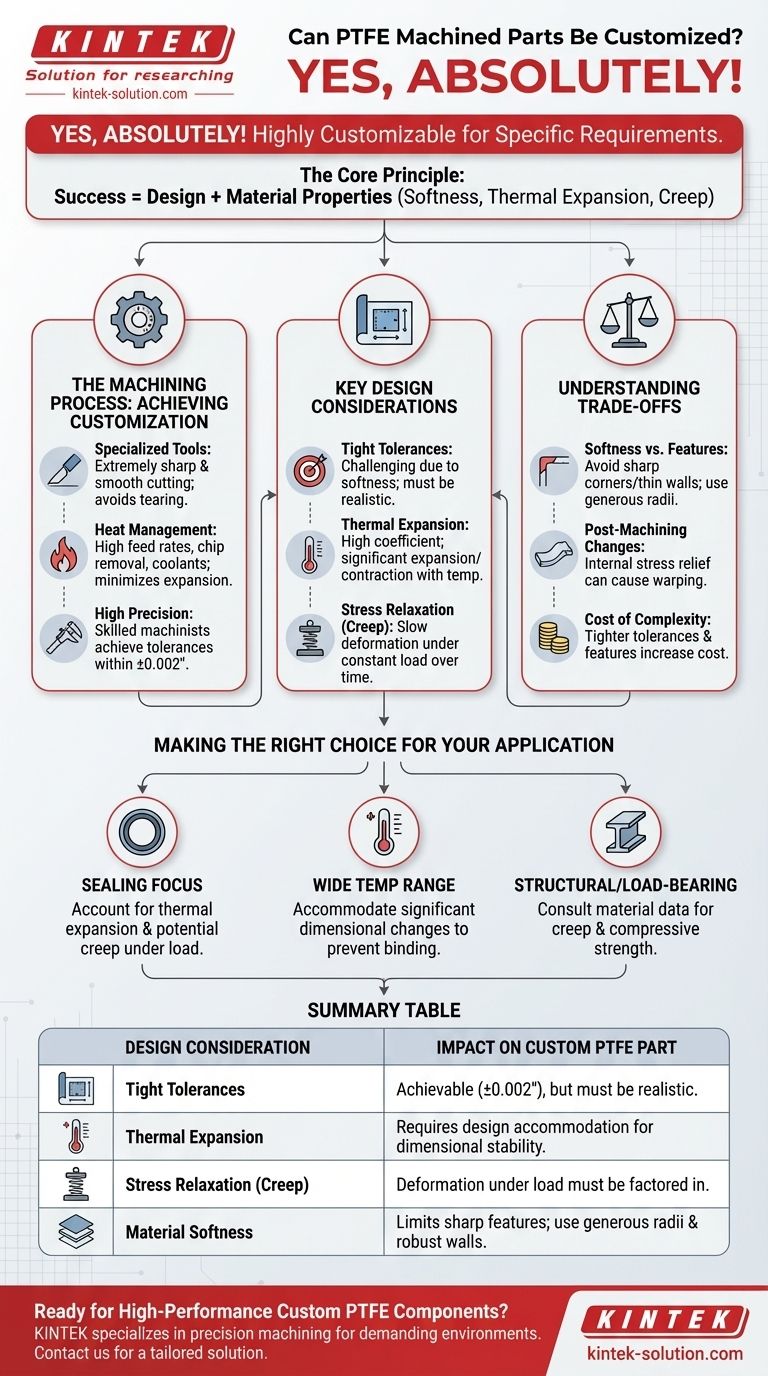

The core principle to understand is that while PTFE is highly customizable, achieving a successful outcome depends entirely on a design that accounts for the material's unique properties—namely, its softness, thermal expansion, and tendency to deform under load.

The Machining Process: How Customization is Achieved

Customizing PTFE is not like machining metal. It is a soft polymer that requires specialized knowledge and techniques to shape it accurately without introducing stress or imperfections.

Specialized Tools and Techniques

Machinists must use extremely sharp and smooth cutting tools. Any dullness or imperfection on the tool can drag or tear the material rather than cutting it cleanly, leading to a poor surface finish and dimensional inaccuracy.

Managing Heat and Material Removal

Although PTFE is known for its high-temperature resistance, friction from machining can generate localized heat. This can cause the material to expand, compromising tolerances.

Effective machinists use high feed rates, proper tool clearance, and efficient swarf (chip) removal to minimize heat buildup. For particularly intensive operations, coolants may be applied.

Achieving High Precision

Despite these challenges, a skilled machinist with the right equipment can achieve remarkable precision. It is common to hold tolerances within ±0.002 inches on many features, enabling the creation of reliable, high-performance parts.

Key Design Considerations for Custom PTFE Parts

The success of a custom PTFE part begins long before the machining process. The design itself must respect the inherent behavior of the material.

The Challenge of Tight Tolerances

While tight tolerances are achievable, they are a primary consideration. Because PTFE is soft, it can be difficult to measure accurately without deflection. The design must specify tolerances that are both necessary for function and realistically achievable.

Accounting for Thermal Expansion

PTFE has a high coefficient of thermal expansion, meaning it expands and contracts significantly with temperature changes. A part designed and measured at room temperature may be out of spec in its final operating environment if this is not accounted for.

Understanding Stress Relaxation (Creep)

Under a constant load, PTFE will slowly deform over time. This phenomenon, known as creep or stress relaxation, is a critical design consideration, especially for sealing applications or parts under constant mechanical pressure.

Understanding the Trade-offs

Customizing PTFE involves balancing its unique benefits with its material limitations. Understanding these trade-offs is crucial for avoiding costly design errors.

Softness vs. Sharp Features

PTFE's softness makes it difficult to machine very sharp internal corners or extremely thin walls. These features can deform during machining or fail under minimal stress. Generous radii and robust wall thicknesses are always preferred.

Post-Machining Dimensional Changes

Internal stresses can be induced during the manufacturing of the raw PTFE stock. When material is machined away, these stresses can be relieved, causing the part to warp or change dimension slightly over time.

Cost of Complexity

As with any manufacturing process, complexity and tighter tolerances directly impact cost. Each additional feature and every tightened tolerance increases machining time, tooling requirements, and the potential for scrap, all of which contribute to a higher final price.

Making the Right Choice for Your Application

To ensure your custom part meets its intended goal, align your design priorities with the material's behavior.

- If your primary focus is high-precision sealing: Specify critical sealing surfaces clearly and work with your machinist to ensure the design accounts for both thermal expansion and potential creep under load.

- If your primary focus is operation across a wide temperature range: Your design must accommodate significant dimensional changes to prevent binding or failure at temperature extremes.

- If your primary focus is a structural or load-bearing component: Consult material data sheets for creep and compressive strength to ensure the part will not deform unacceptably over its service life.

Ultimately, successful PTFE customization is a partnership between a well-informed designer and an experienced machinist.

Summary Table:

| Design Consideration | Impact on Custom PTFE Part |

|---|---|

| Tight Tolerances | Achievable (±0.002 inches), but must be necessary and realistic to avoid deflection. |

| Thermal Expansion | High coefficient requires design accommodation for dimensional stability across temperatures. |

| Stress Relaxation (Creep) | Deformation under constant load must be factored into sealing and structural designs. |

| Material Softness | Limits sharp features and thin walls; generous radii and robust walls are recommended. |

Ready to create high-performance custom PTFE components for your specialized application?

At KINTEK, we specialize in precision machining of PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your custom parts—from prototypes to high-volume orders—are designed to overcome material challenges like thermal expansion and creep, delivering reliable performance in demanding environments.

Contact us today to discuss your specific requirements and let our team provide a solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the overall advantages of using Teflon bushes in industrial settings? Achieve Maintenance-Free Reliability

- How is PTFE utilized in the electronics and electrical industries? | Critical Applications & Benefits

- What is expanded PTFE (ePTFE) and how is it produced? Unlock Superior Sealing and Insulation

- What does the machining process for PTFE parts involve? Mastering Precision for Soft, Heat-Sensitive Materials

- What makes Teflon suitable for use in bearings and similar applications? Discover Its Low-Friction, Chemical-Resistant Advantages

- What are the advantages of using PTFE in plain bearings? Achieve Maintenance-Free, High-Performance Operation

- How does temperature affect PTFE slide bearing performance? Ensure Reliability Under High Heat

- What are the benefits of different spring types used in PTFE seals? Optimize Sealing Performance & Lifespan