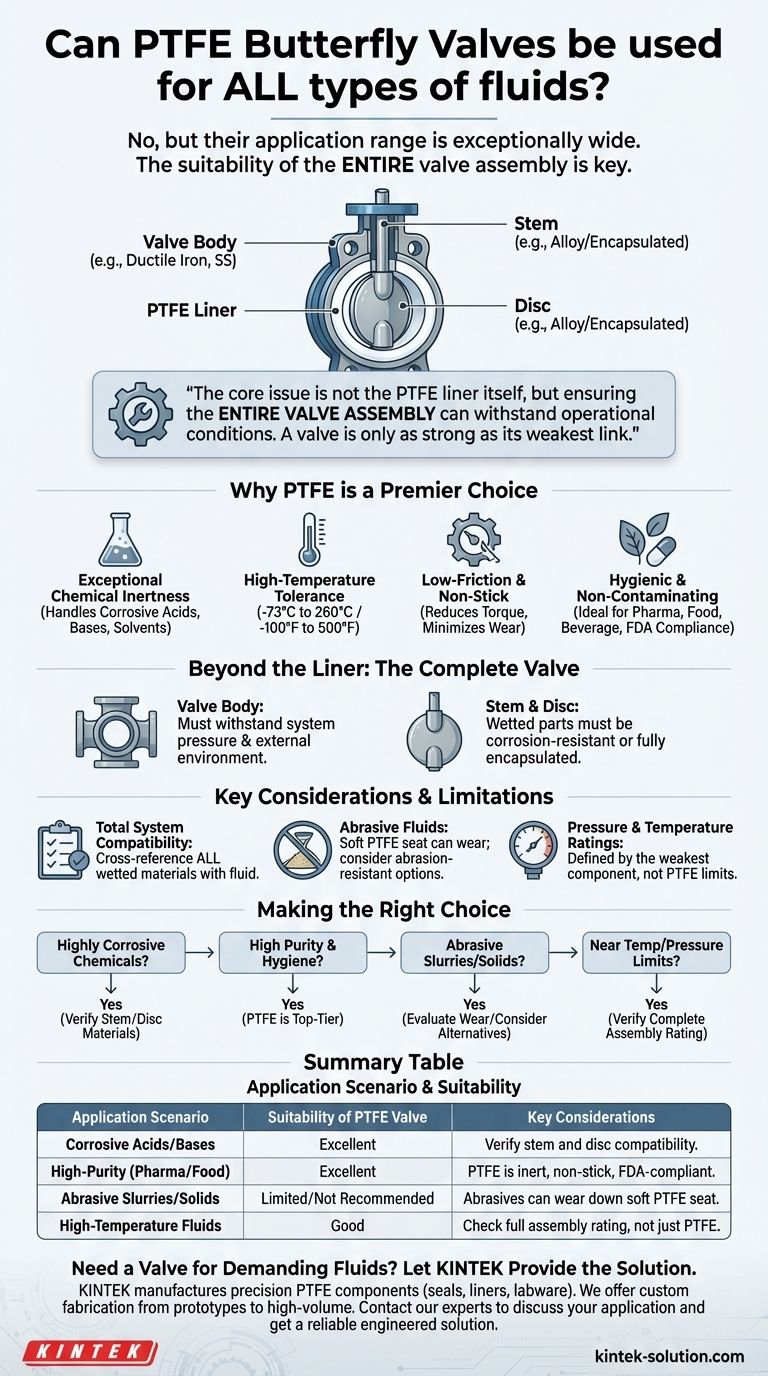

No, PTFE butterfly valves cannot be used for all types of fluids, but their application range is exceptionally wide. While the PTFE (Polytetrafluoroethylene) component is virtually inert to most chemicals, the suitability of the entire valve assembly depends on the compatibility of all its parts—including the body, stem, and disc—with the specific process fluid, temperature, and pressure.

The core issue is not the chemical resistance of the PTFE liner itself, but rather ensuring the entire valve assembly can withstand the specific operational conditions. A PTFE valve is a system of components, and it is only as strong as its weakest link.

Why PTFE is a Premier Choice for Fluid Handling

Polytetrafluoroethylene is a high-performance fluoropolymer renowned for its unique properties, making it a go-to material for demanding industrial applications.

Exceptional Chemical Inertness

PTFE is famous for being non-reactive. It can safely handle a vast spectrum of aggressive fluids, including highly corrosive acids, bases, and solvents, that would degrade most other materials.

High-Temperature Tolerance

This material performs reliably across a broad temperature range, typically from -73°C to 260°C (-100°F to 500°F). This allows its use in processes involving both extreme cold and significant heat.

Low-Friction and Non-Stick Properties

PTFE has one of the lowest coefficients of friction of any solid. This reduces the torque needed to operate the valve, minimizes wear on the seat, and prevents process media from sticking to valve surfaces.

Hygienic and Non-Contaminating

Because PTFE is inert and does not leach substances, it is an ideal choice for applications where purity is critical. It is frequently used in the pharmaceutical, food, and beverage industries and often meets FDA compliance standards.

Beyond the Liner: Understanding the Complete Valve

A common mistake is to focus solely on the PTFE liner. To ensure safe and reliable operation, you must evaluate every component that comes into contact with the fluid or is exposed to the operational environment.

The Role of the Valve Body

The valve body provides the structural integrity. While the liner protects it from the internal fluid, the body material (e.g., ductile iron, stainless steel, carbon steel) must be able to withstand the system pressure and the external environment.

The Importance of the Stem and Disc

The stem and disc are also "wetted parts" that are in direct contact with the fluid. These components must either be made from a corrosion-resistant alloy or be fully encapsulated in PTFE to prevent degradation.

Key Considerations and Potential Limitations

Objectivity requires acknowledging where a PTFE butterfly valve might not be the optimal choice. Understanding these limitations is key to avoiding costly failures.

Verifying Total System Compatibility

You must always cross-reference your specific fluid with a chemical compatibility chart for every single wetted material in the valve assembly, not just the PTFE seat or liner.

Performance with Abrasive Fluids

PTFE is a relatively soft material. If your fluid is a slurry or contains abrasive particulates, these can physically wear away the PTFE seat over time, leading to leaks. In such cases, a more abrasion-resistant seat material may be required.

Pressure and Temperature Ratings

The maximum pressure and temperature rating for the entire valve is determined by its weakest component. The valve's overall rating may be significantly lower than the theoretical limits of PTFE itself due to the constraints of the body, stem, or actuator.

Making the Right Choice for Your Application

Selecting the correct valve is about matching the complete assembly to your specific operational goal. Use these guidelines to make an informed decision.

- If your primary focus is handling highly corrosive chemicals: A PTFE-lined valve is an excellent choice, but you must confirm the disc and stem materials are equally resistant.

- If your process requires high purity and hygiene: PTFE's inert, non-stick, and FDA-compliant properties make it a top-tier and reliable option.

- If your fluid contains abrasive solids or is a slurry: Carefully evaluate the potential for wear on the soft PTFE seat and consider valves designed specifically for abrasive service.

- If you are operating near temperature or pressure limits: Always verify the rating of the complete valve assembly, as this will define your true operational boundary.

Ultimately, a PTFE butterfly valve is a powerful tool for fluid control, provided you account for the entire system, not just a single material.

Summary Table:

| Application Scenario | Suitability of PTFE Butterfly Valve | Key Considerations |

|---|---|---|

| Corrosive Acids/Bases | Excellent | Verify stem and disc material compatibility. |

| High-Purity (Pharma, Food) | Excellent | PTFE is inert, non-stick, and FDA-compliant. |

| Abrasive Slurries/Solids | Limited/Not Recommended | Abrasive particles can wear down the soft PTFE seat. |

| High-Temperature Fluids | Good | Check the valve's full assembly rating, not just PTFE limits. |

Need a Valve for Demanding Fluids? Let KINTEK Provide the Solution.

While PTFE butterfly valves offer exceptional chemical resistance for corrosive acids, bases, and high-purity applications, selecting the right valve assembly is critical to your process's success and safety. The valve is only as strong as its weakest component.

KINTEK manufactures precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and specialized industrial sectors. We understand that a one-size-fits-all approach doesn't work. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders to ensure every component meets your exact operational requirements.

We can help you:

- Select the right materials for all wetted parts (stem, disc) beyond just the liner.

- Design for specific challenges like high temperature, pressure, or abrasive media.

- Ensure system integrity and prevent costly downtime or failures.

Don't leave your fluid handling to chance. Contact our experts today to discuss your application and get a valve solution engineered for reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining