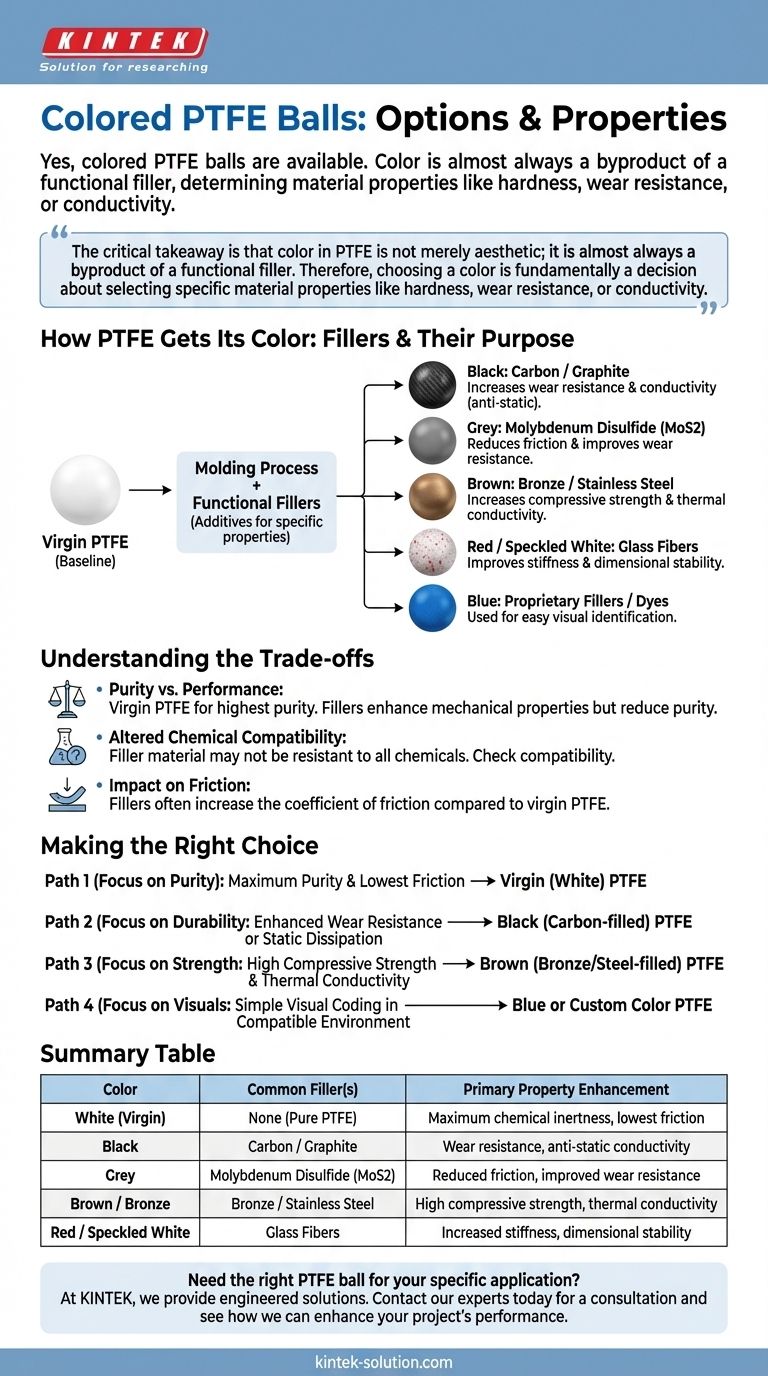

Yes, colored PTFE balls are available. While virgin PTFE is naturally a distinct white or off-white color, various colors can be achieved by blending in specific filler materials before the molding process. These colors are often a direct indicator of the filler used, with common options including black (carbon/graphite), grey (molybdenum disulfide), brown (stainless steel), and red or white speckled (glass).

The critical takeaway is that color in PTFE is not merely aesthetic; it is almost always a byproduct of a functional filler. Therefore, choosing a color is fundamentally a decision about selecting specific material properties like hardness, wear resistance, or conductivity.

How PTFE Gets Its Color: Fillers and Their Purpose

Understanding why a PTFE ball has a particular color is key to making the right engineering choice. The color reveals crucial information about its composition and likely performance characteristics.

Virgin PTFE: The Baseline

The standard for PTFE is virgin grade, which contains no fillers. This material is known for its exceptional chemical inertness and low friction, appearing as a solid, opaque white.

The Role of Functional Fillers

To enhance specific properties, manufacturers blend PTFE resin with other materials. These fillers improve characteristics like compressive strength, thermal conductivity, and resistance to wear and deformation.

The color of the final product is a direct result of the filler material that was added to the base PTFE resin.

Common Colors and Corresponding Fillers

Each color typically corresponds to a specific additive, which imparts distinct properties to the ball.

- Black: This color is achieved by adding carbon or graphite. This significantly increases wear resistance and conductivity, making it ideal for anti-static applications.

- Grey: The addition of molybdenum disulfide (MoS2) creates a grey color. This filler is chosen to reduce friction and improve wear resistance, particularly in dynamic applications.

- Brown: A brown or bronze hue indicates the presence of bronze or stainless steel powder. These metallic fillers dramatically increase compressive strength and thermal conductivity.

- Red / Speckled White: These colors often come from adding glass fibers. Glass improves stiffness and dimensional stability, reducing the tendency of PTFE to creep under load.

- Blue: A solid blue or blue speckled appearance can be achieved with specific proprietary fillers or dyes, often used for easy visual identification in complex systems.

Understanding the Trade-offs of Colored PTFE

While colored, filled PTFE offers enhanced performance, it's essential to understand the associated trade-offs compared to the virgin material.

Performance vs. Purity

The primary trade-off is purity for performance. Adding a filler enhances mechanical properties but changes the material's fundamental composition. For applications requiring the absolute highest chemical inertness, such as in semiconductor or pharmaceutical manufacturing, virgin (white) PTFE is the only suitable choice.

Altered Chemical Compatibility

While PTFE itself is resistant to nearly all chemicals, the filler material may not be. A bronze-filled ball, for example, would not be suitable for use with corrosive agents that attack bronze. You must ensure both the PTFE and its filler are compatible with your application's environment.

Impact on Friction

Fillers can increase the coefficient of friction compared to virgin PTFE. While a carbon-filled ball is much more durable, it will not be as naturally slick as an unfilled white ball.

Making the Right Choice for Your Application

Selecting the correct PTFE ball requires matching the material's properties to your primary goal.

- If your primary focus is maximum chemical purity and the lowest friction: Choose virgin (white) PTFE, as it contains no additives that could leach or react.

- If your primary focus is enhanced wear resistance or static dissipation: Select a black (carbon-filled) PTFE ball for its durability and conductive properties.

- If your primary focus is high compressive strength and thermal conductivity: A brown (bronze or stainless steel-filled) ball is the most effective option.

- If your primary focus is simple visual coding in a compatible environment: A solid blue or other custom-blended color serves as an excellent identifier.

Ultimately, selecting a colored PTFE ball is a decision about defining your required material properties first and using color as a guide to achieve them.

Summary Table:

| Color | Common Filler(s) | Primary Property Enhancement |

|---|---|---|

| White (Virgin) | None (Pure PTFE) | Maximum chemical inertness, lowest friction |

| Black | Carbon / Graphite | Wear resistance, anti-static conductivity |

| Grey | Molybdenum Disulfide (MoS2) | Reduced friction, improved wear resistance |

| Brown / Bronze | Bronze / Stainless Steel | High compressive strength, thermal conductivity |

| Red / Speckled White | Glass Fibers | Increased stiffness, dimensional stability |

Need the right PTFE ball for your specific application?

At KINTEK, we don't just supply standard components—we provide engineered solutions. Our expertise in custom PTFE fabrication ensures you get the exact material properties you need, whether it's virgin PTFE for ultimate purity or a filled grade for enhanced performance.

We serve a wide range of industries, including semiconductor, medical, and laboratory, where precision and material compatibility are critical. Let us help you select or custom-manufacture the perfect PTFE ball, from prototypes to high-volume orders.

Contact our experts today for a consultation and see how we can enhance your project's performance.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What temperature can heat-resistant Teflon sheets withstand? Up to 500°F for Reliable Performance

- What are the installation requirements for PTFE Lined Butterfly Valves? Ensure Long-Term Reliability & Prevent Failure

- How do modern CNC machines contribute to energy efficiency in Teflon machining? Achieve Precision and Sustainability

- How does the friction performance of PTFE oil seals compare to conventional oil seals? Boost Efficiency & Durability

- What lining materials can be chosen for PTFE/PFA lined ball valves? Select the Right Liner for Your Corrosive Process

- What are the properties of Modified Polytetrafluoroethylene? Enhanced Performance for Demanding Applications

- How can the disadvantages of PTFE processing machines be mitigated? Manage Trade-offs for Optimal Performance

- What are the three types of PTFE materials used for gaskets? Select the Right Seal for Your Application