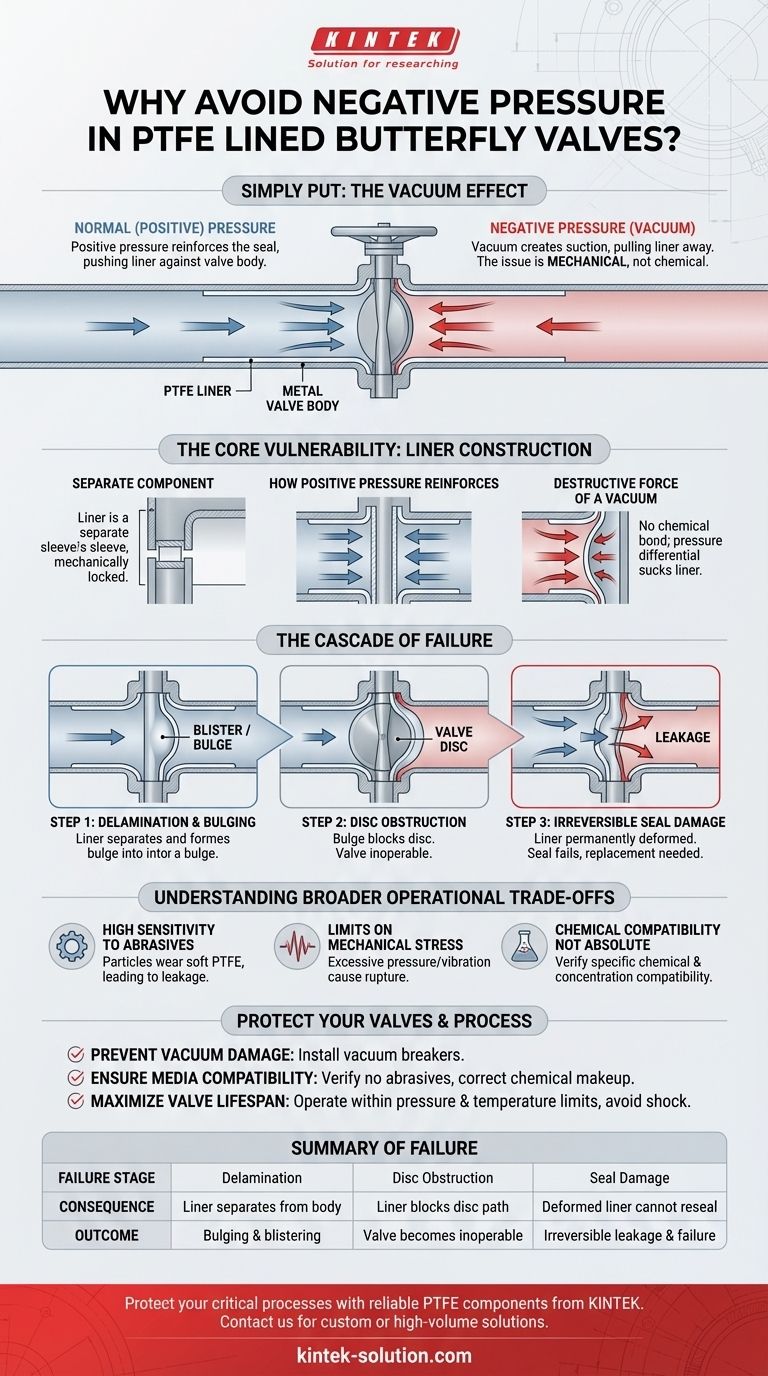

Simply put, negative pressure in a pipeline creates a vacuum effect that can physically pull the PTFE liner away from the inner wall of the valve body. This causes the liner to delaminate, bulge, or tear, leading to immediate obstruction of the valve disc and catastrophic seal failure.

The central issue is mechanical, not chemical. A PTFE liner is a separate sleeve pressed into the valve's metal body, not fused to it. Negative pressure exploits this physical separation, sucking the liner inward and destroying the valve's ability to function.

The Core Vulnerability: Liner Construction and Pressure Dynamics

To understand why negative pressure is so uniquely destructive to these valves, you first have to understand how they are built and how normal pressure interacts with them.

The Liner is a Separate Component

A PTFE lined butterfly valve is not a solid piece of PTFE. It consists of a rigid metal body (like cast iron or stainless steel) that has a separate, pre-formed sleeve of PTFE mechanically locked or pressed into place.

This design is highly effective at isolating corrosive media from the structural metal body.

How Positive Pressure Reinforces the Seal

During normal operation with positive pressure, the force of the fluid pushes the PTFE liner firmly against the interior surface of the valve body.

This pressure actually helps seat the liner, reinforcing its position and ensuring a tight seal around the valve disc.

The Destructive Force of a Vacuum

Negative pressure, or a vacuum condition, completely reverses this dynamic. The pressure inside the pipeline drops below the atmospheric pressure outside the valve.

This pressure differential creates a powerful suction force that pulls the liner inward, away from the valve body and into the pipeline. Since the liner is not chemically bonded, there is little to resist this force.

The Cascade of Failure: From Vacuum to Malfunction

Once a vacuum condition occurs, it sets off a rapid and typically irreversible chain of events that ruins the valve.

Step 1: Delamination and Bulging

The initial effect of the vacuum is delamination, where the liner separates from the metal valve body.

This separation often results in a "blister" or bulge, where a section of the liner is sucked into the flow path.

Step 2: Disc Obstruction

This bulge physically blocks the path of the butterfly disc. This can make the valve impossible to fully close or, in some cases, impossible to open. The valve is now inoperable.

Step 3: Irreversible Seal Damage

Even if the negative pressure is corrected, the liner is now deformed. It will no longer sit flush against the valve body or create a proper seal with the disc.

When positive pressure returns, the system will almost certainly experience significant leakage past the damaged liner. At this point, the valve has failed and must be replaced.

Understanding Broader Operational Trade-offs

While negative pressure is the most acute threat, it's critical to recognize other operational limits of PTFE lined valves to ensure system reliability.

High Sensitivity to Abrasives

The medium flowing through the valve must not contain hard particles, crystals, or other abrasive impurities.

PTFE is a relatively soft material. Abrasives will quickly wear down the liner and the disc seal, leading to leakage and premature failure.

Limits on Mechanical Stress

Excessive pressure spikes or high-vibration environments can also cause damage. A sudden, extreme pressure difference can physically stress the liner beyond its limits, potentially causing a rupture.

Chemical Compatibility Is Not Absolute

While PTFE offers outstanding resistance to a wide range of chemicals, it is not invincible. You must always verify that the specific chemical composition and concentration of your media are compatible with PTFE at the designated operating temperature.

Protecting Your Valves and Your Process

Understanding these failure modes is the key to preventing them. Proper system design and operational procedures are not optional—they are essential for leveraging the benefits of these valves.

- If your primary focus is preventing vacuum damage: Your system must include vacuum breakers or other engineering controls to ensure negative pressure conditions can never occur.

- If your primary focus is media compatibility: You must verify your media is free of abrasive particles and that its chemical makeup is fully compatible with PTFE specifications.

- If your primary focus is maximizing valve lifespan: Operate strictly within the valve's published pressure and temperature ratings and implement proper system startup and shutdown procedures to avoid shock.

By respecting these operational boundaries, you can ensure your PTFE lined valves provide the safe, long-term, and corrosion-resistant service they were designed for.

Summary Table:

| Failure Stage | Consequence | Outcome |

|---|---|---|

| Delamination | Liner separates from valve body | Bulging and blistering |

| Disc Obstruction | Liner blocks butterfly disc path | Valve becomes inoperable |

| Seal Damage | Deformed liner cannot reseal | Irreversible leakage and failure |

Protect your critical processes with reliable PTFE components from KINTEK.

Our precision-manufactured PTFE seals, liners, and labware are engineered to withstand the demanding conditions of semiconductor, medical, laboratory, and industrial applications. We understand the catastrophic effects of negative pressure and design our components with your operational safety in mind.

Whether you need custom prototypes or high-volume production, KINTEK delivers the precision and reliability your system requires. Contact our experts today to discuss your specific application and ensure your valves operate within safe parameters.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What manufacturing processes are used for PTFE seals? From Molding to Machining for Peak Performance

- Why is PTFE packing considered a reliable and cost-effective option? Maximize Uptime & Lower Costs

- How should cooling be managed during Teflon machining? Prevent Warping & Ensure Precision

- How does PTFE prevent corrosion in piping systems? A Complete Guide to Chemical & Galvanic Protection

- What are PTFE washers made of? Unlocking the Power of Carbon-Fluorine Chemistry

- What advantages do PTFE expansion bellows have over metal bellows in corrosive environments? Superior Chemical Resistance for Longer Lifespan

- How does the inelasticity of PTFE affect its use in sealing applications? Understand the Critical Trade-offs for Reliability

- What customization options are available for PTFE sheets? Engineer the Perfect Material for Your Application