To successfully machine Teflon (PTFE), material support is critical because the material is exceptionally soft, slippery, and prone to deforming under the slightest cutting or clamping pressure. Proper support is achieved not just by holding the material, but by using custom fixtures that distribute clamping force evenly, employing razor-sharp tools that shear rather than push the material, and managing heat to prevent dimensional changes.

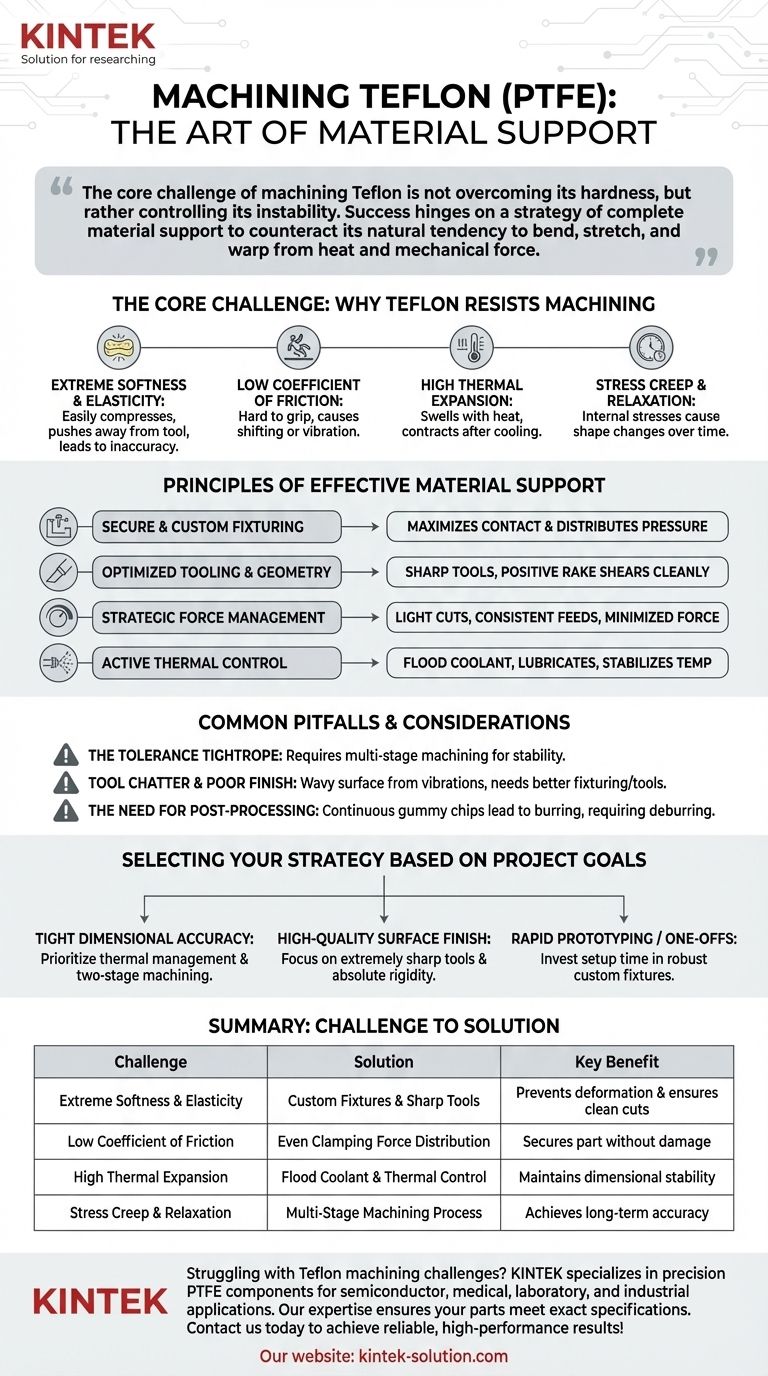

The core challenge of machining Teflon is not overcoming its hardness, but rather controlling its instability. Success hinges on a strategy of complete material support to counteract its natural tendency to bend, stretch, and warp from heat and mechanical force.

The Core Challenge: Why Teflon Resists Conventional Machining

To understand how to support Teflon, you must first understand the unique combination of properties that make it so difficult to work with. Unlike metals or even most other plastics, Teflon's primary characteristics actively work against standard machining processes.

### Extreme Softness and Elasticity

Teflon is incredibly soft, meaning it easily compresses and bends when a cutting tool applies pressure. Instead of a clean chip forming, the material can simply push away from the tool, leading to inaccurate dimensions and a poor surface finish.

### Low Coefficient of Friction

While its slipperiness is an advantage in finished parts, it is a significant liability during manufacturing. This property makes Teflon notoriously difficult to grip securely in a vise or chuck without deforming it, causing parts to shift or vibrate during machining.

### High Thermal Expansion

Teflon expands and contracts significantly with temperature changes. The friction from a cutting tool generates localized heat, causing the material to swell in that area. This leads to inaccurate cuts that may only become apparent after the part cools and shrinks back down.

### Stress Creep and Relaxation

Even after a part is machined, internal stresses can cause it to slowly change shape over time, a phenomenon known as stress creep or relaxation. A part that is perfectly in-spec right off the machine may be out of tolerance hours later.

Principles of Effective Material Support

Counteracting these challenges requires a multi-faceted approach where support is provided through fixturing, tooling, and process control.

### Secure and Custom Fixturing

Standard machine vises with jaw teeth are unsuitable as they will mar and deform the part. The best practice is to create custom jigs or fixtures that conform to the part's shape, maximizing surface contact to distribute clamping pressure evenly and prevent distortion.

### Optimized Tooling and Geometry

The right tool is a form of support. Extremely sharp tools with high positive rake angles are essential. These tools shear the material cleanly with minimal pressure, reducing heat generation and preventing the material from pushing away. HSS or uncoated carbide tools are effective.

### Strategic Force Management

Machining Teflon is an exercise in finesse, not force. Using light depths of cut and consistent feed rates is critical. This minimizes the force exerted on the material, preventing it from deforming and reducing the risk of tool chatter.

### Active Thermal Control

Using a flood coolant is highly effective. It serves two purposes: lubricating the cut to reduce friction and, more importantly, carrying away heat to stabilize the material's dimensions and prevent thermal expansion from ruining tolerances.

Common Pitfalls and Considerations

Even with the right strategy, machining Teflon presents unique trade-offs that you must manage to achieve a successful outcome.

### The Tolerance Tightrope

Achieving very tight tolerances is the primary challenge due to thermal expansion and stress creep. For critical dimensions, it is often necessary to machine parts slightly oversized, let them rest and stabilize for several hours, and then perform a final, light finishing pass.

### Tool Chatter and Poor Finish

Vibrations, known as tool chatter, are common if the material is not held securely or if the cutting tool is dull. This results in a wavy, unacceptable surface finish and must be addressed by improving fixturing or sharpening tools.

### The Need for Post-Processing

Due to its softness, Teflon produces a continuous, gummy chip and is prone to burring. Expect to perform manual deburring after machining to achieve a clean, finished part.

Selecting Your Strategy Based on Project Goals

Your approach should be tailored to the most critical outcome for your specific component.

- If your primary focus is achieving tight dimensional accuracy: Prioritize thermal management with coolants and plan for a two-stage machining process that allows the material to relax and stabilize.

- If your primary focus is a high-quality surface finish: Concentrate on using extremely sharp, high-rake tools and ensure your workpiece is fixtured with absolute rigidity to eliminate all chatter.

- If your primary focus is rapid prototyping or one-off parts: Invest the majority of your setup time in creating a robust, custom fixture, as a single instance of the part slipping will be more costly than the extra time spent on preparation.

By treating Teflon with finesse rather than force, you can consistently transform its challenging properties into high-performance components.

Summary Table:

| Challenge | Solution | Key Benefit |

|---|---|---|

| Extreme Softness & Elasticity | Custom Fixtures & Sharp Tools | Prevents deformation & ensures clean cuts |

| Low Coefficient of Friction | Even Clamping Force Distribution | Secures part without damage |

| High Thermal Expansion | Flood Coolant & Thermal Control | Maintains dimensional stability |

| Stress Creep & Relaxation | Multi-Stage Machining Process | Achieves long-term accuracy |

Struggling with Teflon machining challenges? KINTEK specializes in precision PTFE components for semiconductor, medical, laboratory, and industrial applications. Our expertise in custom fixturing, thermal management, and tooling strategies ensures your parts meet exact specifications—from prototypes to high-volume production. Contact us today to discuss your project and achieve reliable, high-performance results!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts