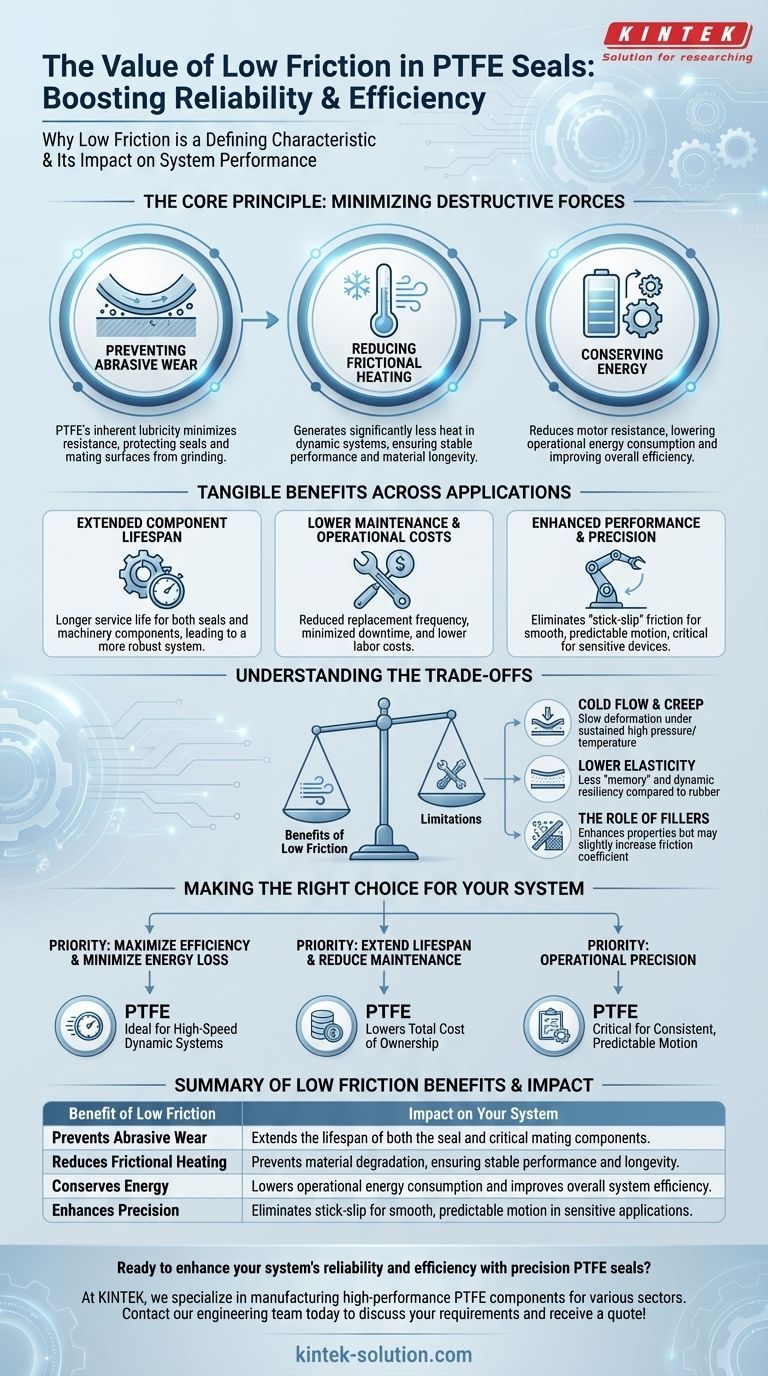

Low friction is the defining characteristic of PTFE seals because it directly translates to reduced wear on critical components, lower energy consumption, and enhanced overall system reliability. It prevents the seal and its mating surfaces from grinding against each other, which is the primary cause of premature failure in dynamic applications.

The value of low friction in PTFE seals extends far beyond simple smoothness. It is a fundamental property that minimizes destructive forces—wear, heat, and energy loss—thereby extending component life, improving operational efficiency, and lowering long-term maintenance costs.

The Core Principle: Minimizing Destructive Forces

The low coefficient of friction in Polytetrafluoroethylene (PTFE), typically between 0.04 and 0.15, is not just a feature; it is the mechanism that prevents three key sources of system degradation.

Preventing Abrasive Wear

High-friction materials act like a fine abrasive, slowly grinding away at both the seal and the surface it moves against, such as a rotating shaft.

PTFE's inherent lubricity allows it to glide across mating surfaces with minimal resistance. This drastically reduces wear, protecting the integrity of both the seal and the expensive components it contacts.

Reducing Frictional Heating

All friction generates heat. In high-speed or high-pressure dynamic systems, this heat can build up rapidly.

Excessive heat can cause the seal material to degrade, harden, or lose its shape, leading to seal failure. By minimizing friction, PTFE seals generate significantly less heat, ensuring stable performance and material longevity.

Conserving Energy

Friction is a form of resistance that a system's motor or actuator must overcome. This requires energy.

In systems like hydraulic and pneumatic machinery, reducing friction means less energy is wasted. This translates directly to improved efficiency and lower operational energy consumption over the life of the equipment.

Tangible Benefits Across Applications

The reduction of these destructive forces produces clear, measurable advantages in any mechanical system.

Extended Component Lifespan

By preventing abrasive wear and thermal degradation, PTFE seals ensure that both the seal itself and the machinery's components last longer. This leads to a more robust and reliable system.

Lower Maintenance and Operational Costs

A longer service life directly reduces the frequency of replacements, minimizes costly equipment downtime, and lowers labor costs associated with maintenance.

Enhanced Performance and Precision

In sensitive equipment, such as medical devices or aerospace actuators, "stick-slip" friction can cause jerky, imprecise movements.

PTFE's consistent, low-friction glide ensures smooth, predictable operation. This is critical in applications like catheters, where smooth navigation is essential for procedural success and patient comfort.

Understanding the Trade-offs

While its low friction is a powerful advantage, PTFE is not universally perfect. Understanding its limitations is key to proper application.

Cold Flow and Creep

Under sustained high pressure or temperature, PTFE has a tendency to slowly deform or "creep." This can eventually compromise sealing integrity in certain static applications.

The Role of Fillers

To counteract creep and enhance wear resistance, PTFE is often blended with fillers like glass fiber, carbon, or bronze. These fillers improve mechanical properties but can slightly increase the coefficient of friction compared to virgin PTFE.

Lower Elasticity

Compared to traditional rubber elastomers, PTFE is a more rigid material. It has less "memory" or ability to bounce back from deformation, making it less suitable for applications requiring high dynamic resiliency.

Making the Right Choice for Your System

Selecting a seal is a decision about system performance. The benefits of PTFE's low friction align with specific engineering goals.

- If your primary focus is maximizing efficiency and minimizing energy loss: PTFE's ultra-low friction is your greatest asset, making it ideal for high-speed dynamic systems where every watt of power counts.

- If your primary focus is extending component lifespan and reducing maintenance: The material's ability to prevent wear on both the seal and mating surfaces directly lowers the total cost of ownership.

- If your primary focus is operational precision in sensitive applications: The smooth, stick-slip-free movement enabled by PTFE is critical for devices requiring consistent and predictable motion.

Ultimately, selecting a PTFE seal is a strategic decision to build a more durable, efficient, and reliable mechanical system.

Summary Table:

| Benefit of Low Friction | Impact on Your System |

|---|---|

| Prevents Abrasive Wear | Extends the lifespan of both the seal and critical mating components. |

| Reduces Frictional Heating | Prevents material degradation, ensuring stable performance and longevity. |

| Conserves Energy | Lowers operational energy consumption and improves overall system efficiency. |

| Enhances Precision | Eliminates stick-slip for smooth, predictable motion in sensitive applications. |

Ready to enhance your system's reliability and efficiency with precision PTFE seals?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production ensures that you get the exact low-friction solution you need, from rapid prototypes to high-volume orders.

Let us help you reduce maintenance costs, extend component life, and improve operational precision. Contact our engineering team today to discuss your specific requirements and receive a quote!

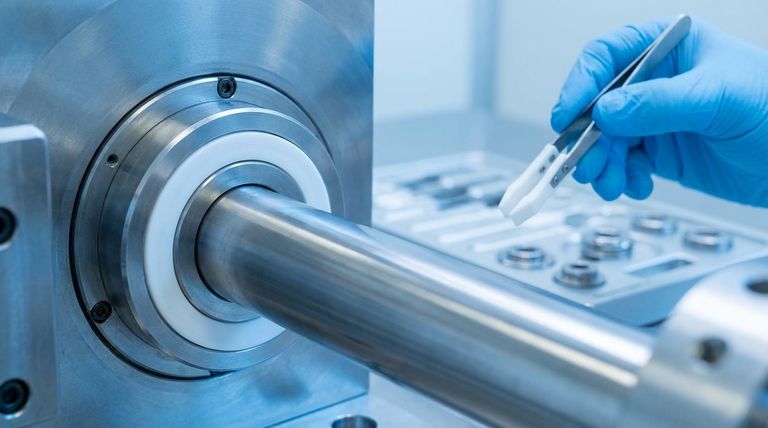

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the limitations of PTFE bellows? Understanding Its Mechanical and Chemical Boundaries

- What material are PTFE heat press sheets made from? Unlock Consistent, Professional Results

- How does the material composition of Teflon backup rings vary? A Guide to Virgin vs. Filled PTFE

- What is the primary function of PTFE pneumatic valves? Control Corrosive Media with Unmatched Reliability

- Why is PTFE suitable for mechanisms that rotate or slide? Achieve Maintenance-Free, Low-Friction Motion

- What factors affect the choice between Teflon and parchment for heat pressing? Achieve the Perfect Finish Every Time

- How does chemical resistance benefit PTFE washers? Ensure Unmatched Reliability in Harsh Environments

- What are the self-lubricating properties of PTFE rod? Achieve Low-Friction, Maintenance-Free Performance