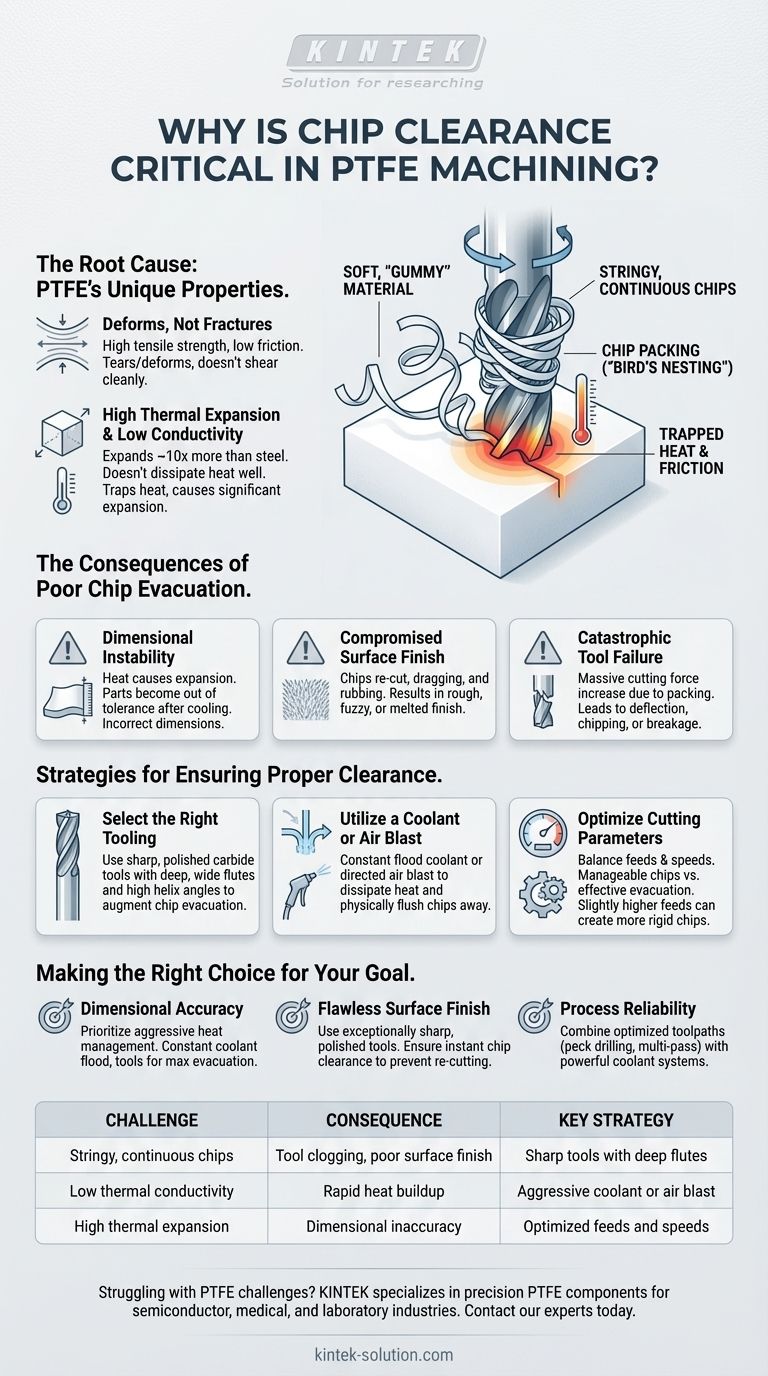

In PTFE machining, effective chip clearance is critical to prevent clogging. Because PTFE is a soft, "gummy" material, it produces long, continuous, stringy chips that do not break easily. These chips can quickly wrap around the tool and workpiece, leading to catastrophic part failure, poor surface finish, and potential tool damage.

The core challenge in machining PTFE is not cutting the material itself, but managing its unique properties. Prioritizing chip clearance is the primary strategy for controlling heat buildup and preventing the material's high thermal expansion from ruining your work.

The Root Cause: PTFE's Unique Material Properties

To understand the importance of chip clearance, you first have to understand how PTFE behaves under a cutting tool. Unlike metals that produce small, brittle chips, PTFE reacts very differently.

A Material That Deforms, Not Fractures

PTFE is exceptionally soft and has a low coefficient of friction. When you cut it, it tends to tear or deform rather than shear cleanly.

This behavior results in the formation of long, ribbon-like swarf that has a high tensile strength. These chips do not naturally break into manageable pieces.

The Problem of Chip Packing

These continuous, stringy chips have a tendency to wrap around the rotating tool, creating a "bird's nest."

This tangled mass can pack into the tool's flutes, completely preventing any new chips from being evacuated. At this point, the tool stops cutting and starts rubbing, generating immense friction and heat.

The Connection to Heat Buildup

PTFE has very low thermal conductivity, meaning it doesn't dissipate heat well. It also has a very high rate of thermal expansion—about ten times that of steel.

When chips pack around the tool, they trap heat directly at the cutting point. This localized heat causes the material to expand significantly, making it impossible to maintain dimensional accuracy.

The Consequences of Poor Chip Evacuation

Failing to manage chip clearance leads directly to the most common problems encountered when machining PTFE. Every major failure can be traced back to this single issue.

Dimensional Instability

As trapped chips generate heat, the PTFE expands. A hole being drilled will become smaller, and a diameter being turned will become larger. Once the part cools, it will be dimensionally incorrect and out of tolerance.

Compromised Surface Finish

When chips are not cleared effectively, they are often re-cut by the tool. This dragging and rubbing action mars the surface, leaving a rough, fuzzy, or melted finish instead of a clean, smooth cut.

Catastrophic Tool Failure

A tool completely clogged with packed chips experiences a massive increase in cutting forces. This can easily lead to the tool deflecting, chipping, or breaking entirely, potentially damaging the workpiece and the machine spindle.

Strategies for Ensuring Proper Clearance

Successful PTFE machining relies on a system designed to actively and aggressively remove chips from the cutting zone.

Select the Right Tooling

Standard metal-cutting tools are not ideal. Use sharp carbide tools with highly polished surfaces and deep, wide flutes designed for soft materials. A high helix angle on an endmill, for example, acts like an auger to pull chips up and out of a pocket.

Utilize a Coolant or Air Blast

A constant flood of coolant serves two critical purposes: it dissipates the heat generated during the cut and physically flushes the stringy chips away from the tool.

In situations where liquid coolant cannot be used, a directed blast of compressed air can also be effective at blowing chips clear.

Optimize Cutting Parameters

While low cutting speeds are often recommended to reduce heat, it's a balancing act. The goal is to use feeds and speeds that produce a manageable chip while allowing for effective evacuation. Sometimes, a slightly higher feed rate can create a more rigid chip that is easier for the coolant to push away.

Making the Right Choice for Your Goal

Your machining strategy should be dictated by the most critical feature of your final part.

- If your primary focus is tight dimensional accuracy: Prioritize aggressive heat management with a constant flood of coolant and tooling designed for maximum chip evacuation.

- If your primary focus is a flawless surface finish: Use exceptionally sharp, polished tools and ensure chips are cleared instantly to prevent any re-cutting or rubbing.

- If your primary focus is process reliability for production: Combine optimized toolpaths (like peck drilling or multi-pass milling) with a powerful coolant system to guarantee chips never have a chance to pack.

Ultimately, mastering chip clearance is the key to machining PTFE with precision and repeatability.

Summary Table:

| Challenge | Consequence | Key Strategy |

|---|---|---|

| Stringy, continuous chips | Tool clogging, poor surface finish | Sharp tools with deep flutes |

| Low thermal conductivity | Rapid heat buildup | Aggressive coolant or air blast |

| High thermal expansion | Dimensional inaccuracy | Optimized feeds and speeds |

Struggling with PTFE machining challenges? KINTEK specializes in precision PTFE components for the semiconductor, medical, and laboratory industries. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your parts are machined to the highest standards, with chip clearance and thermal management optimized for your application. Contact our experts today to discuss your project and achieve reliable, repeatable results.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts