In pharmaceutical applications, chemical compatibility is a non-negotiable requirement for diaphragm valves. Its importance stems from the need to prevent the valve's material from degrading when exposed to process fluids, which directly ensures product purity, prevents catastrophic process failures, and guarantees patient safety.

The core issue extends beyond simple valve durability. In a regulated environment like pharmaceuticals, chemical incompatibility is a critical failure point that can lead to product contamination, batch rejection, and significant safety risks. The right material selection is a foundational element of process integrity.

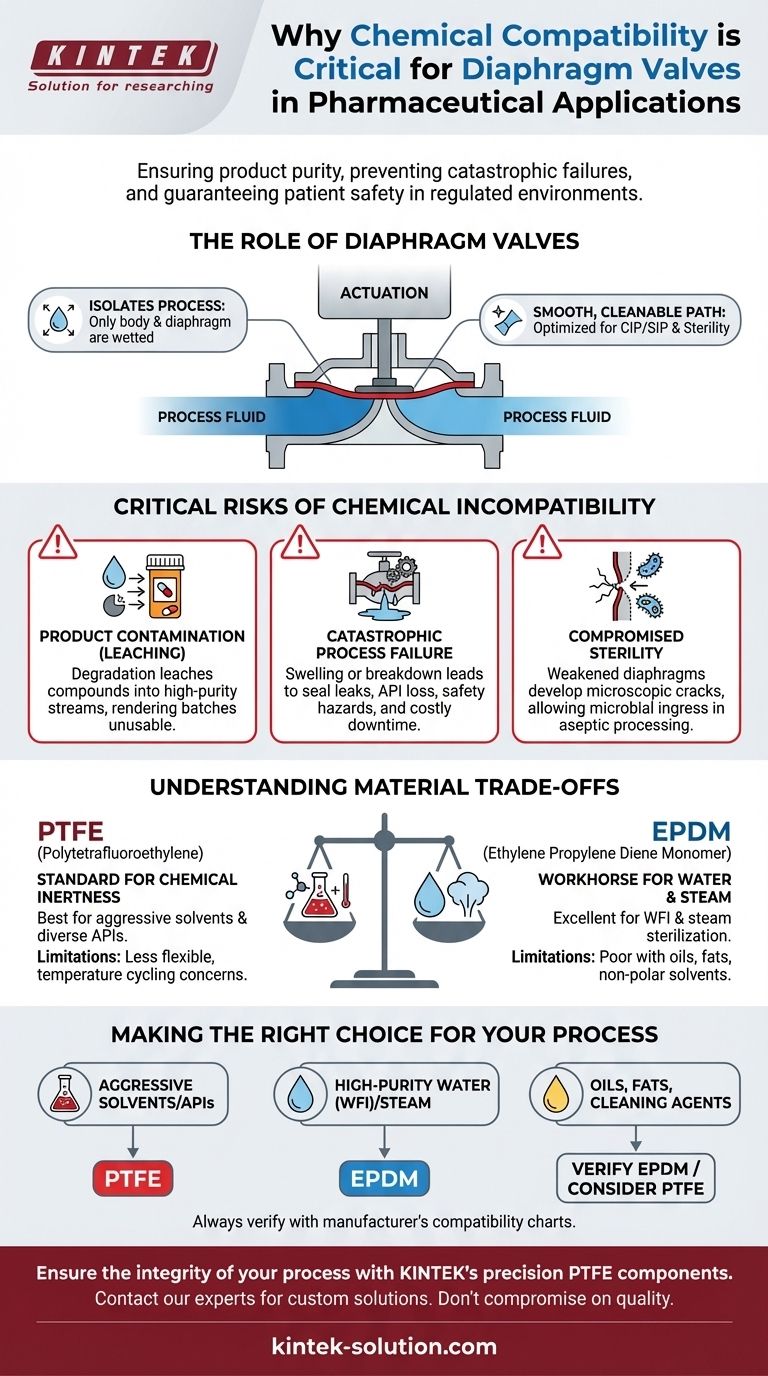

The Role of Diaphragm Valves in High-Purity Systems

Diaphragm valves are ubiquitous in pharmaceutical manufacturing due to their unique design, which is inherently clean and minimizes the risk of contamination.

A Design That Isolates the Process

The defining feature of a diaphragm valve is a flexible membrane (the diaphragm) that separates the process fluid from the valve's actuation mechanism. This means the only "wetted" parts are the valve body and the diaphragm itself.

This design eliminates potential contamination sources found in other valve types, such as packing or crevices in stems.

A Smooth and Cleanable Fluid Path

These valves provide a smooth, pocket-less flow path when open. This geometry is crucial for effective Clean-in-Place (CIP) and Sterilize-in-Place (SIP) procedures, preventing the buildup of product residue or microbial biofilms.

The Critical Risks of Chemical Incompatibility

Selecting a diaphragm material that is not compatible with the process fluid, cleaning agents, or sterilization temperatures introduces unacceptable risks.

Product Contamination via Leaching

If a diaphragm material degrades, it can leach chemical compounds directly into the high-purity process stream. This contaminates the final drug product, rendering an entire batch unusable and potentially harmful to patients.

Catastrophic Process Failure

Chemical attack can cause the diaphragm to swell, harden, or physically break down. This leads to seal failure, causing leaks that result in the loss of valuable active pharmaceutical ingredients (APIs), safety hazards for operators, and costly unscheduled downtime.

Compromised Sterility

In aseptic (sterile) processing, the diaphragm forms a critical barrier against microbial ingress. A chemically weakened or degraded diaphragm can develop microscopic cracks, compromising the sterility of the entire system and leading to product loss.

Understanding the Trade-offs: Common Diaphragm Materials

The choice of diaphragm material is a careful balance of chemical resistance, temperature rating, and application. No single material is perfect for every situation.

PTFE: The Standard for Chemical Inertness

Polytetrafluoroethylene (PTFE) is renowned for its exceptional resistance to a wide range of chemicals, including aggressive solvents and acids. It is often the default choice for multi-product facilities where valves will encounter diverse compounds.

However, PTFE can be less flexible and have limitations regarding temperature cycling and long-term sealing performance under certain mechanical stresses.

EPDM: The Workhorse for Water and Steam

Ethylene Propylene Diene Monomer (EPDM) offers excellent performance with water, including Water-for-Injection (WFI), and is highly resistant to steam sterilization. It is a common and cost-effective choice for high-purity water loops and many buffer solutions.

Its primary limitation is poor compatibility with non-polar solvents, oils, and fats, which will cause it to swell and degrade quickly.

The Need for Verification

Always consult the manufacturer’s chemical compatibility charts. These guides provide essential data on how materials perform against specific chemicals at various concentrations and temperatures. For novel applications, direct material testing is often required.

Making the Right Choice for Your Process

Your selection must be guided by the specific demands of the fluid stream and operating conditions.

- If your primary focus is handling aggressive solvents or diverse APIs: PTFE is the safest and most versatile choice due to its superior chemical resistance.

- If your primary focus is on high-purity water systems (WFI) or steam applications: EPDM is typically the most reliable and cost-effective material.

- If your process involves oils, fats, or certain cleaning agents: You must verify compatibility against EPDM and may need to consider alternative materials like PTFE.

Ultimately, meticulous material selection for chemical compatibility is a cornerstone of safe, compliant, and efficient pharmaceutical manufacturing.

Summary Table:

| Key Risk of Incompatibility | Consequence | Common Material & Use Case |

|---|---|---|

| Leaching & Contamination | Product impurity, batch rejection | PTFE: Aggressive solvents, diverse APIs |

| Diaphragm Degradation | Seal failure, leaks, downtime | EPDM: High-purity water (WFI), steam (SIP) |

| Compromised Sterility | Microbial ingress, product loss | Material selection is critical for aseptic processing |

Ensure the integrity of your pharmaceutical process with KINTEK's precision PTFE components.

Selecting the right diaphragm material is non-negotiable for product purity and patient safety. KINTEK specializes in manufacturing high-performance PTFE seals, liners, and custom labware designed for the demanding environments of the semiconductor, medical, and laboratory industries. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get chemically compatible components that protect your product and your process.

Don't compromise on quality. Contact our experts today to discuss your specific application needs and receive a custom solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What flange types are PTFE envelope gaskets compatible with? Versatile Sealing for Every Industry

- What are the basic materials used in slide bearings? Explore PTFE, Composites & Multi-Layer Designs

- What are the common types of glass reinforcements used in PTFE-based materials? Optimize Performance for Your Application

- How does the non-stick surface of PTFE benefit seals? Unlock Self-Cleaning Performance and Reliability

- In what types of air compressors are PTFE oil scraper rings commonly used? A Guide to High-Performance Sealing

- How does chemical resistance benefit PTFE washers? Ensure Unmatched Reliability in Harsh Environments

- What materials are used to manufacture PTFE bars? A Guide to Virgin & Filled PTFE

- How can users obtain customized PTFE gaskets and sheets? Get Precision Parts for Your Industry