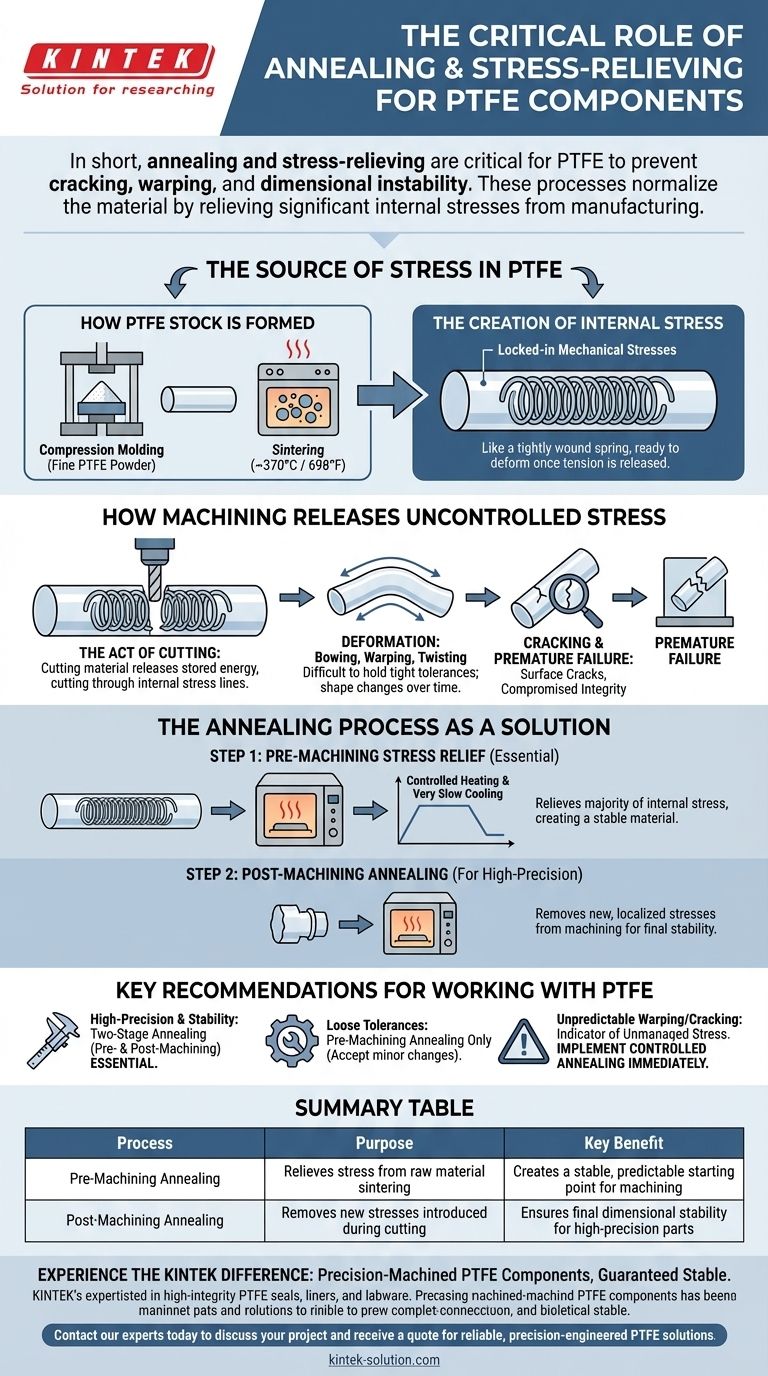

In short, annealing and stress-relieving are critical for PTFE to prevent cracking, warping, and dimensional instability. These processes normalize the material by relieving the significant internal stresses created during its manufacturing, ensuring that a machined part maintains its intended shape and structural integrity over time.

The core issue is that PTFE is not melt-processed like other plastics; it is compression molded and sintered from a powder. This unique manufacturing method locks immense stress into the raw material, which will be released unpredictably during machining unless it is properly stabilized through annealing.

The Source of Stress in PTFE

How PTFE Stock is Formed

Unlike plastics that are melted and injected into a mold, PTFE is created through a process of compression and sintering.

Fine PTFE powder is compressed under extreme pressure into a solid shape, known as a billet. This billet is then heated in an oven to a temperature around 370°C (698°F), a process called sintering, which fuses the particles together.

The Creation of Internal Stress

This compression and heating process does not fully melt the material into a relaxed, uniform state. Instead, it creates a solid with significant locked-in mechanical stresses.

You can think of the raw PTFE rod or sheet as being filled with stored energy, like a tightly wound spring, ready to move and deform once that tension is released.

How Machining Releases Uncontrolled Stress

The Act of Cutting

When you machine PTFE, you are cutting away material and, in doing so, cutting through the lines of internal stress. This releases the stored energy.

The Consequence: Deformation

The release of stress is rarely uniform across the part. As you remove material from one side, the stresses on the opposite side can cause the part to bow, warp, or twist.

This movement makes holding tight tolerances exceptionally difficult. A component might measure perfectly just after a cut, only to change shape hours later as the remaining stresses slowly redistribute themselves.

Cracking and Premature Failure

In severe cases, the concentration of stress in certain areas can exceed the material's strength, leading to surface cracks. These cracks compromise the part's integrity and can lead to premature failure in its final application.

The Annealing Process as a Solution

Step 1: Pre-Machining Stress Relief

The most critical step is to anneal the raw PTFE stock before any significant machining begins. The material is heated slowly, held at a specific temperature, and then cooled very slowly.

This controlled cycle allows the polymer chains to relax and realign, releasing the vast majority of the internal stress from the sintering process. This creates a far more stable and predictable material to work with.

Step 2: Post-Machining Annealing

Even after the initial stress relief, the act of machining itself can introduce new, localized stresses into the part.

For high-precision components, a second annealing cycle is often performed after rough machining but before the final finishing passes. This step removes the new stresses, ensuring the part is completely stable for the final, high-tolerance cuts.

Key Recommendations for Working with PTFE

- If your primary focus is high-precision and dimensional stability: A two-stage annealing process (both pre- and post-machining) is absolutely essential.

- If your part has loose tolerances and is not structurally critical: You may proceed with only a pre-machining annealing cycle, but you must accept the risk of some minor dimensional changes.

- If you are experiencing unpredictable warping or cracking: This is a clear indicator that your material's internal stress is not being managed. Implement a proper, controlled annealing cycle immediately.

Ultimately, viewing annealing not as an optional step but as a fundamental part of the fabrication process is the key to successfully machining reliable PTFE components.

Summary Table:

| Process | Purpose | Key Benefit |

|---|---|---|

| Pre-Machining Annealing | Relieves stress from raw material sintering | Creates a stable, predictable starting point for machining |

| Post-Machining Annealing | Removes new stresses introduced during cutting | Ensures final dimensional stability for high-precision parts |

Experience the KINTEK Difference: Precision-Machined PTFE Components, Guaranteed Stable.

Don't let internal stress compromise your critical PTFE parts. KINTEK specializes in manufacturing high-integrity PTFE seals, liners, and labware with a thorough understanding of the annealing process. We ensure every component, from prototypes to high-volume orders, delivers unmatched dimensional stability and longevity for the semiconductor, medical, and laboratory industries.

Contact our experts today to discuss your project and receive a quote for reliable, precision-engineered PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications