In any heat transfer project, a Teflon sheet acts as the essential barrier between your design and the intense heat of your press. Its primary functions are to provide a non-stick surface, protect your garment from scorching, and shield your equipment from residue. These three functions work together to ensure a clean, damage-free, and professional result every time.

The intense heat required for transfer can easily ruin both your project and your equipment by causing materials to melt, stick, or scorch. A Teflon sheet solves this fundamental problem by creating a reusable, non-stick, and heat-resistant shield that guarantees a clean release and protects your investment.

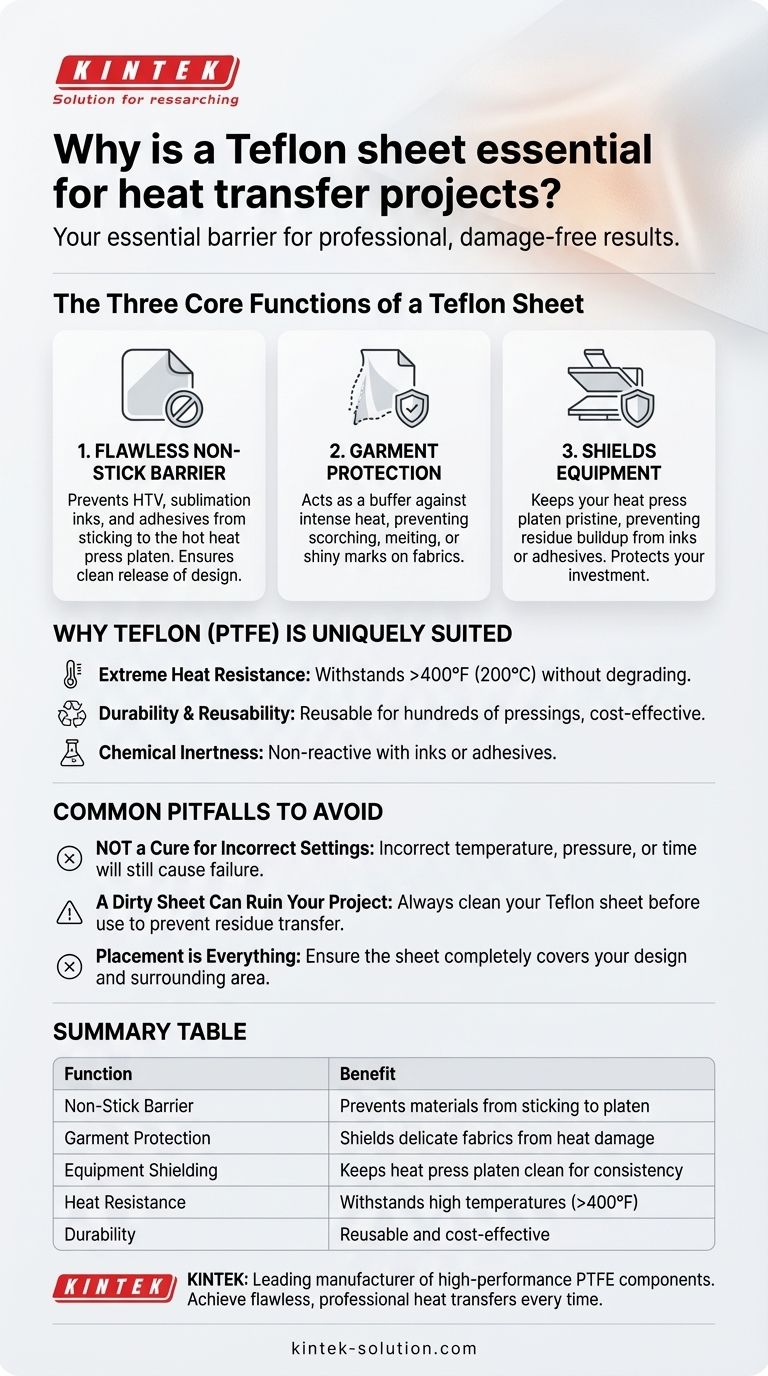

The Three Core Functions of a Teflon Sheet

A Teflon sheet isn't just an accessory; it's a critical component that performs three distinct jobs simultaneously. Understanding these roles clarifies why it is considered indispensable for quality work.

Creating a Flawless Non-Stick Barrier

The most immediate problem a Teflon sheet solves is adhesion. Heat transfer vinyls (HTV), sublimation inks, and other transfer materials can easily stick to the hot metal surface of a heat press platen.

This non-stick surface ensures that your design remains solely on the garment. It prevents any part of the transfer, especially stray adhesive or ink, from melting onto your platen, which would ruin both the current project and potentially stain future ones.

Protecting Your Garment from Scorching

Direct contact with a high-temperature metal platen can damage many fabrics. Materials like polyester or delicate blends can scorch, melt, or develop a permanent "shiny" mark from the heat.

The Teflon sheet acts as a protective buffer. It distributes the heat more evenly and creates a gentle barrier between the raw heat source and the fabric, significantly reducing the risk of heat damage.

Shielding Your Heat Press Platen

Your heat press is a significant investment, and its upper platen is its most critical component. Residue from inks, adhesives, or melted vinyl can permanently damage its coating.

By always placing a Teflon sheet over your design, you keep the platen pristine. This practice ensures consistent performance over the life of the machine and prevents old residues from being accidentally transferred onto new projects.

Why Teflon is Uniquely Suited for the Job

While other materials might be used as a temporary barrier, Teflon (PTFE) has specific properties that make it the ideal material for heat press applications.

Extreme Heat Resistance

Teflon sheets are engineered to withstand the high temperatures required for heat transfer—often exceeding 400°F (200°C)—without degrading, melting, or releasing harmful fumes. This stability is its most crucial feature.

Durability and Reusability

Unlike parchment paper, which degrades quickly with heat, a high-quality Teflon sheet can be wiped clean and reused for hundreds or even thousands of pressings. This makes it a cost-effective and reliable tool in any workflow.

Chemical Inertness

Teflon is chemically non-reactive. This means it won't interact with the dyes in sublimation ink or the chemicals in transfer adhesives, ensuring the transfer process happens exactly as intended without any interference.

Common Pitfalls to Avoid

While essential, a Teflon sheet is a tool, not a magic fix. To get the best results, you must avoid common mistakes that can compromise its effectiveness.

It's Not a Cure for Incorrect Settings

A Teflon sheet cannot compensate for incorrect temperature, pressure, or time settings. If your settings are wrong for the material you are using, your transfer will still fail, even with a protective sheet.

A Dirty Sheet Can Ruin Your Project

Always ensure your Teflon sheet is clean before use. Any stray ink, adhesive, or debris left on the sheet from a previous job can easily be transferred to your new garment. A quick wipe-down is a critical step.

Placement is Everything

The sheet must completely cover your design and the immediate surrounding area. If any part of the design or transfer paper is exposed and touches the platen, you negate the protective benefits of the sheet.

How to Apply This to Your Project

Your specific use case will determine which benefit of the Teflon sheet is most critical for your success.

- If your primary focus is Heat Transfer Vinyl (HTV): The non-stick surface is non-negotiable to prevent the vinyl's carrier sheet and any exposed adhesive from melting onto your press.

- If your primary focus is Sublimation: The sheet is essential to prevent inks from gassing through the paper and permanently staining your heat platen, a common issue known as "ghosting."

- If your primary focus is working with delicate fabrics: Use the sheet as a universal pressing cloth to prevent scorching or shiny marks, even when not applying a design.

Ultimately, incorporating a Teflon sheet into your workflow is one of the simplest and most effective steps toward achieving consistently professional heat transfer results.

Summary Table:

| Function | Benefit |

|---|---|

| Non-Stick Barrier | Prevents HTV, ink, and adhesive from sticking to the heat press platen. |

| Garment Protection | Shields delicate fabrics like polyester from scorching, melting, or shiny marks. |

| Equipment Shielding | Keeps the heat press platen clean from residue, ensuring consistent performance and longevity. |

| Heat Resistance | Withstands temperatures exceeding 400°F (200°C) without degrading. |

| Durability | Reusable for hundreds of pressings, making it a cost-effective solution. |

Achieve flawless, professional heat transfers every time with a reliable barrier.

As a leading manufacturer of high-performance PTFE components, KINTEK understands the critical need for durability and precision in heat-intensive applications. Our Teflon sheets are engineered for superior heat resistance and non-stick performance, protecting your valuable equipment and ensuring perfect project results.

Whether you are applying Heat Transfer Vinyl (HTV), sublimating, or working with delicate fabrics, our sheets provide the essential protection you need. We offer custom fabrication from prototypes to high-volume orders to meet your specific requirements.

Protect your investment and elevate your craft. Contact KINTEK today to find the perfect Teflon sheet solution for your heat transfer projects!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance