In aggressive media environments, PTFE rotary shaft seals are preferred for one primary reason: exceptional chemical inertness. Unlike traditional elastomer seals that swell, degrade, or dissolve when exposed to harsh chemicals, PTFE remains stable and effective. This fundamental resilience against a vast range of industrial acids, solvents, and fuels prevents seal failure and protects critical equipment.

The selection of a seal is not just about resisting a single chemical. PTFE is the superior choice because its unique combination of near-universal chemical inertness, high-temperature tolerance, and low-friction performance provides a uniquely reliable solution for the most demanding operational conditions.

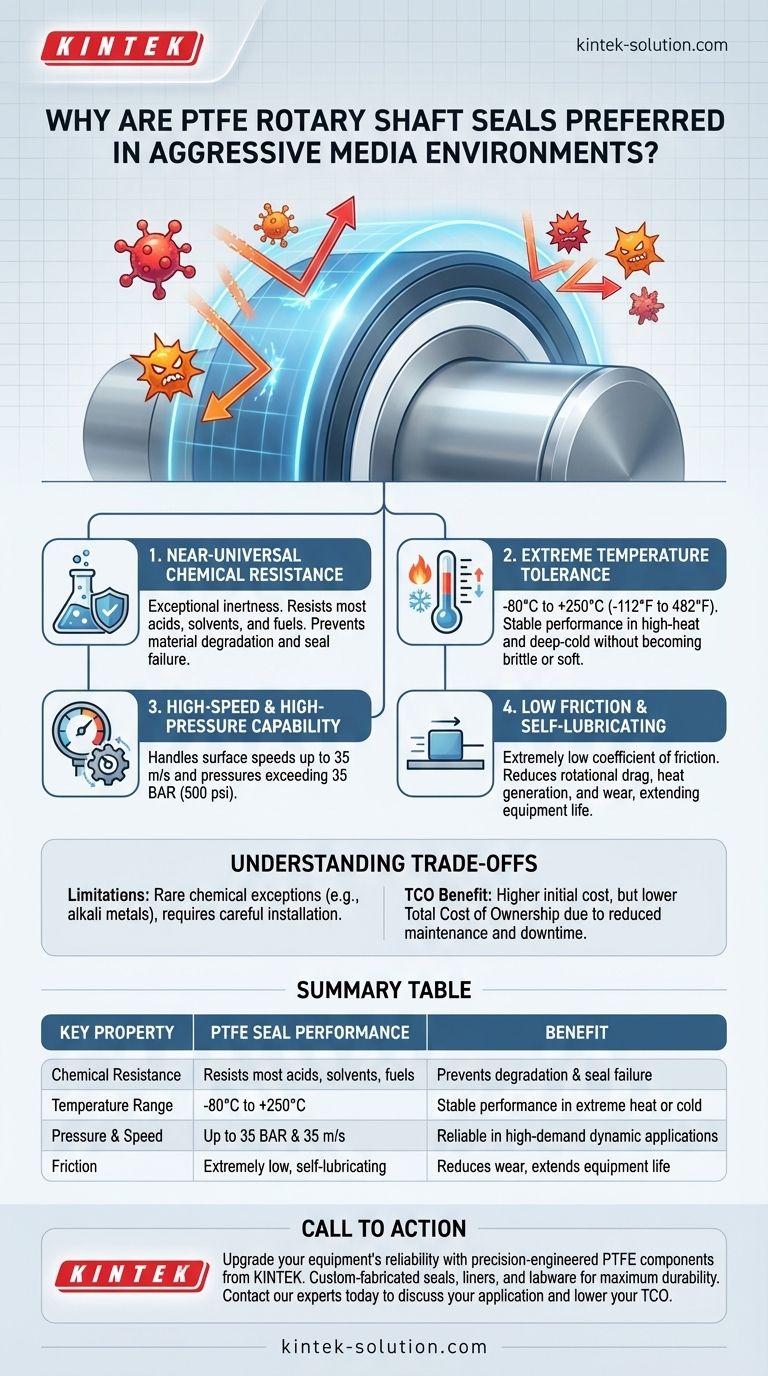

The Core Advantage: Near-Universal Chemical Resistance

The fundamental value of Polytetrafluoroethylene (PTFE) lies in its molecular structure, which renders it non-reactive to most substances. This makes it an ideal barrier in applications where seal failure is not an option.

Resilience Against Corrosive Acids and Solvents

PTFE effectively resists common industrial corrosives like hydrochloric acid, sulfuric acid, and organic solvents. This prevents the material degradation, swelling, or hardening that plagues conventional seals, ensuring a consistent seal over the equipment's lifespan.

Compatibility with Aggressive Fuels and Oils

In automotive, aerospace, and oil and gas industries, seals are constantly exposed to chemically aggressive oils, diesel, gasoline, and hydrocarbon-based fuels. PTFE's compatibility with these fluids makes it one of the most reliable polymers for these applications.

Stability in Processing Environments

From chemical processing to food and dairy production, PTFE seals maintain their integrity when exposed to substances like acetone, citric acid, and sodium peroxide. This broad resistance minimizes contamination risk and reduces the need for frequent, costly maintenance cycles.

Performance Beyond Chemical Stability

While its chemical resilience is paramount, PTFE's superiority is cemented by a range of other high-performance physical properties. These characteristics work in concert to ensure reliability under extreme mechanical stress.

High-Temperature Operation

PTFE seals function reliably across an exceptionally wide temperature range, typically from -80°C to +250°C (-112°F to 482°F). This allows them to maintain sealing integrity in high-heat applications without becoming brittle or soft.

High-Speed and High-Pressure Capability

These seals are engineered for demanding dynamic applications. They can handle surface speeds up to 35 m/s and operating pressures exceeding 35 BAR (500 psi), far surpassing the limits of many standard elastomeric seals.

The Benefit of Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. Its self-lubricating properties reduce rotational drag and heat generation, which minimizes wear on both the seal and the shaft, thereby extending the life of the entire assembly.

Understanding the Trade-offs and Limitations

No material is a universal solution. An objective assessment requires understanding PTFE's limitations to ensure it is correctly specified for an application.

Specific Chemical Exceptions

While resistant to most chemicals, PTFE can be attacked by a very small number of rare substances. These include certain alkali metals and highly reactive fluorinating agents. It is always critical to verify compatibility with the specific media in your system.

Installation and Design Considerations

PTFE is a more rigid material than common elastomers like nitrile or viton. This relative lack of elasticity means proper installation procedures and tools are essential to avoid damaging the seal lip during assembly.

Cost vs. Total Cost of Ownership

PTFE seals often have a higher initial purchase price compared to some traditional seals. However, this cost is frequently justified by a lower total cost of ownership, achieved through significantly reduced maintenance, less downtime, and longer overall equipment life.

Making the Right Choice for Your Application

Selecting the correct seal material is a critical engineering decision based on your primary operational challenges.

- If your primary focus is handling highly corrosive chemicals: PTFE is the default choice due to its near-universal inertness, which prevents material degradation and ensures long-term seal integrity.

- If your primary focus is high-speed and high-temperature performance: PTFE's ability to operate at extreme velocities and temperatures without significant wear makes it superior to most traditional elastomers.

- If your primary focus is maximizing uptime and equipment life: The combined durability, low friction, and chemical resistance of PTFE leads to a lower total cost of ownership in demanding environments.

Ultimately, selecting a PTFE rotary shaft seal is an investment in operational reliability where other materials would fail.

Summary Table:

| Key Property | PTFE Seal Performance | Benefit |

|---|---|---|

| Chemical Resistance | Resists most acids, solvents, fuels | Prevents degradation and seal failure |

| Temperature Range | -80°C to +250°C | Stable performance in extreme heat or cold |

| Pressure & Speed | Up to 35 BAR & 35 m/s | Reliable in high-demand dynamic applications |

| Friction | Extremely low, self-lubricating | Reduces wear, extends equipment life |

Upgrade your equipment's reliability with precision-engineered PTFE components from KINTEK.

If your operations involve aggressive chemicals, extreme temperatures, or high-speed machinery, our custom-fabricated PTFE seals, liners, and labware are designed for maximum durability and performance. We serve the semiconductor, medical, laboratory, and industrial sectors with prototypes and high-volume orders.

Contact our experts today to discuss how our PTFE solutions can reduce downtime and lower your total cost of ownership.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are other names for Teflon encapsulated silicone o-rings? Find the Right High-Performance Seal

- Can a Teflon sheet be used for sublimation printing? Enhance Print Quality & Protect Equipment

- Why is Teflon's heat resistance important in food processing? Ensure Safety and Efficiency

- What are the steps involved in the PTFE lining process? A Guide to Durable Chemical Resistance

- What pressure considerations apply to PTFE lined butterfly valves? Avoid Liner Failure and Ensure Safe Operation

- What precautions should be taken during the installation of PTFE gasket seals? Ensure a Perfect, Leak-Free Seal

- What are the common applications of PTFE oil seals? Master Sealing in Extreme Conditions

- Why are PTFE sheets used in the medical industry? For Biocompatibility, Inertness & Low Friction