In short, PTFE lined pipes are essential because they offer a combination of chemical inertness, high-temperature resistance, and non-stick properties that is unmatched by other materials. This makes them the safest and most reliable solution for transporting highly corrosive, reactive, or high-purity fluids that would quickly destroy standard piping systems.

The decision to use PTFE lined pipe is not simply about corrosion resistance. It is a strategic choice to guarantee process integrity, ensure operational safety, and achieve long-term cost-effectiveness in demanding industrial environments where failure is not an option.

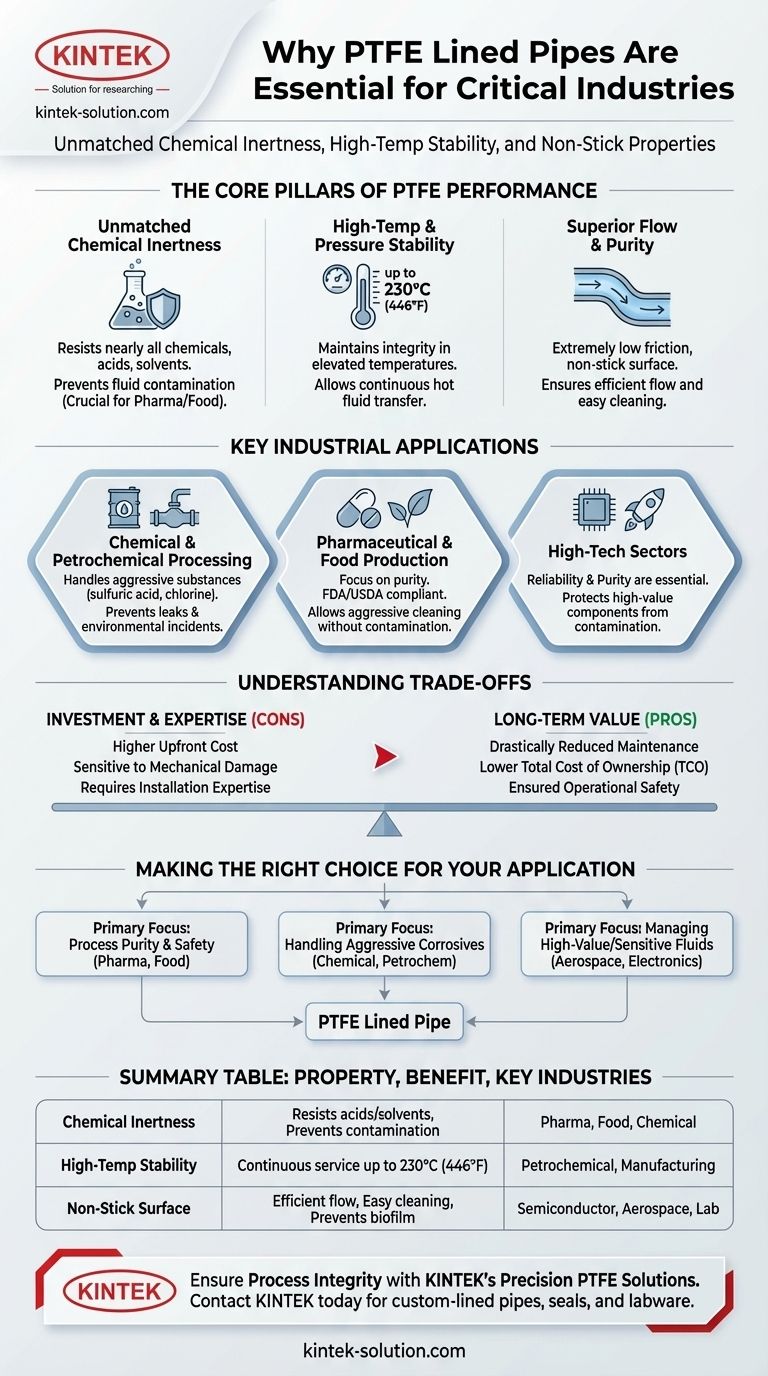

The Core Pillars of PTFE Performance

To understand why PTFE is indispensable, we need to look beyond the surface and analyze its fundamental material properties. These characteristics work together to solve critical challenges in industrial fluid handling.

Unmatched Chemical Inertness

Polytetrafluoroethylene (PTFE) is one of the most chemically inert substances known. It is virtually immune to attack from almost all industrial chemicals, acids, and solvents.

This inertness is a two-way benefit. It protects the outer pipe (typically carbon or stainless steel) from being corroded by the fluid inside, but just as importantly, it prevents the pipe from contaminating the fluid. This is non-negotiable in pharmaceutical and food production.

High-Temperature and Pressure Stability

Many industrial processes operate at elevated temperatures. PTFE maintains its structural integrity and chemical resistance at continuous service temperatures up to 230°C (446°F).

This allows industries to run chemical reactions and transfer hot fluids without risking a catastrophic failure of the piping system, expanding the operational window for many processes.

Superior Flow and Purity

PTFE has an extremely low coefficient of friction, creating a "non-stick" surface. This property is critical for two reasons.

First, it ensures efficient flow and reduces the energy required to pump fluids. Second, it prevents material from sticking to the pipe walls, which minimizes the risk of cross-contamination and the buildup of biofilms in sanitary applications.

Key Industrial Applications

The unique properties of PTFE make it the go-to solution for the most challenging applications across several key sectors.

For Chemical and Petrochemical Processing

These industries regularly handle highly aggressive substances like sulfuric acid, chlorine, and caustic soda. PTFE lined pipes provide the long-term, maintenance-free containment needed to handle these fluids safely and prevent costly environmental incidents.

For Pharmaceutical and Food Production

Purity is the primary concern in these fields. Certain grades of PTFE are FDA and USDA compliant. Its non-reactive and non-stick surface ensures the product remains uncontaminated and allows for aggressive steam or chemical cleaning cycles between batches.

For High-Tech Sectors

In industries like aerospace and electronics manufacturing, specialized and often corrosive chemicals are used in controlled environments. PTFE's reliability and purity are essential for producing high-performance components where any contamination could lead to failure.

Understanding the Trade-offs

While its performance is exceptional, PTFE is not a universal solution. A trusted advisor must acknowledge its limitations to ensure it is specified correctly.

The Upfront Cost Factor

PTFE lined pipe carries a higher initial material cost compared to standard carbon steel or even some stainless steel alloys. This is an investment in long-term performance, not a low-cost commodity.

The higher upfront cost is almost always offset by drastically reduced maintenance, replacement, and downtime costs over the life of the system, resulting in a lower total cost of ownership.

Sensitivity to Mechanical Damage

PTFE is a relatively soft material. While protected by a metal housing, the lining can be damaged by severe abrasion from sharp solids within the fluid stream or by improper handling and installation practices.

The Need for Installation Expertise

The reliability of a PTFE lined piping system depends heavily on proper installation. Correctly torquing bolts and ensuring flange faces are perfectly aligned is critical to creating a durable, leak-free seal. This often requires specialized training and tools.

Making the Right Choice for Your Application

Selecting the correct piping material is a critical engineering decision. Use these guidelines to determine if PTFE is the right choice for your goal.

- If your primary focus is process purity and safety (Pharmaceuticals, Food): PTFE is often the only acceptable choice due to its inertness, cleanability, and regulatory compliance.

- If your primary focus is handling aggressive corrosives (Chemicals, Petrochemicals): PTFE provides the most reliable long-term protection against costly leaks and system failure, ensuring operational safety and environmental protection.

- If your primary focus is managing high-value or sensitive fluids (Aerospace, Electronics): The non-contaminating nature of PTFE protects your final product and prevents expensive batch loss.

Ultimately, specifying PTFE lined pipe is a decision to prioritize long-term system reliability and integrity over short-term material cost.

Summary Table:

| Property | Benefit | Key Industries |

|---|---|---|

| Chemical Inertness | Resists almost all acids, solvents; prevents contamination | Pharmaceutical, Food, Chemical |

| High-Temp Stability | Continuous service up to 230°C (446°F) | Petrochemical, Manufacturing |

| Non-Stick Surface | Ensures efficient flow, easy cleaning, prevents biofilm | Semiconductor, Aerospace, Lab |

Ensure process integrity and long-term cost savings with KINTEK's precision PTFE solutions.

KINTEK specializes in manufacturing high-performance PTFE components—including custom-lined pipes, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, guarantees a solution tailored to your specific fluid handling challenges, ensuring safety, purity, and reliability.

Contact KINTEK today to discuss your application requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is chip clearance important in PTFE machining? Prevent Clogging and Ensure Precision

- What are the key benefits of using PTFE gaskets? Achieve Unmatched Chemical & Temperature Resistance

- What types of industries and applications utilize PTFE parts? Discover the Versatility of PTFE

- What are the general advantages of using Teflon coating in industrial applications? Boost Efficiency & Protect Equipment

- How does PTFE's molecular structure contribute to its non-stick properties? The Science Behind Its Slick Surface

- What are the shapes and dimensions of PTFE sliding bearing pads? Rectangular & Circular Load Solutions

- How does the high temperature resistance of PTFE processing machines benefit their operation? Ensuring Reliable, High-Quality Production

- What role do Teflon PTFE sheets play in sewing projects? Achieve Flawless, Professional Results