At their core, PTFE lined butterfly valves are popular in industrial applications because they offer an exceptional combination of chemical inertness, wide temperature tolerance, and reliable sealing. This unique blend of features allows them to handle harsh, corrosive materials that would quickly degrade standard valves, making them a cost-effective and durable solution for challenging flow control problems.

The true value of a PTFE lined butterfly valve isn't just one feature, but how the PTFE lining transforms a standard valve into a highly resilient and versatile workhorse. It effectively isolates the valve's structural components from corrosive media, providing the performance of exotic alloys for a fraction of the cost.

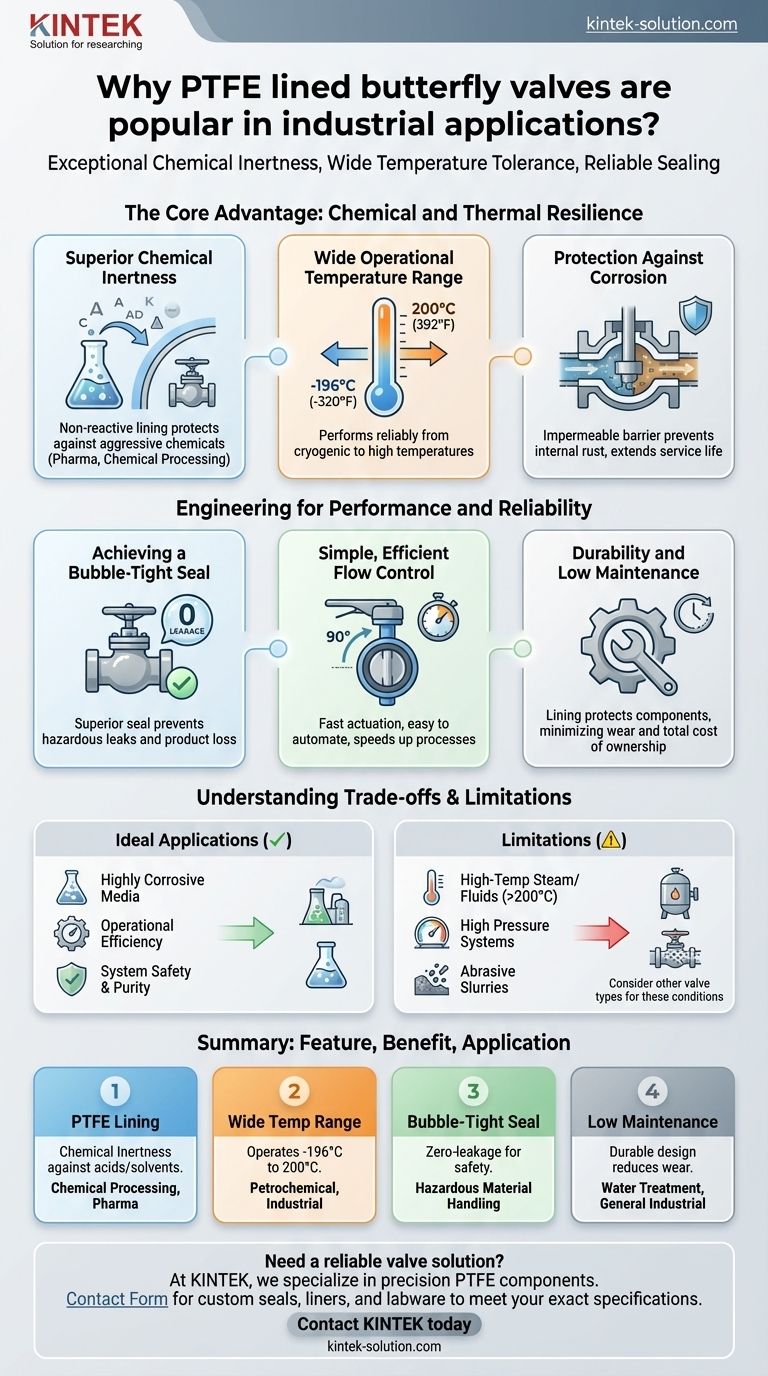

The Core Advantage: Chemical and Thermal Resilience

The primary reason for selecting a PTFE lined valve is its ability to survive in environments where others fail. This resilience stems directly from the properties of Polytetrafluoroethylene (PTFE).

Superior Chemical Inertness

PTFE is one of the most non-reactive materials known. This makes it an ideal lining for valves handling aggressive and corrosive media.

It provides robust protection against a wide range of chemicals, including strong acids, bases, and solvents that are common in chemical processing, petrochemical, and pharmaceutical industries.

Wide Operational Temperature Range

These valves are engineered to perform reliably across a broad spectrum of temperatures.

Most PTFE lined valves can operate in conditions ranging from -196°C to 200°C (-320°F to 392°F), making them suitable for both cryogenic and moderately high-temperature processes.

Protection Against Corrosion

The PTFE lining acts as an impermeable barrier, completely isolating the valve body and stem from the process fluid.

This prevents internal corrosion and rust, dramatically extending the valve's service life and ensuring the purity of the media passing through it.

Engineering for Performance and Reliability

Beyond its material advantages, the design of a PTFE lined butterfly valve is optimized for efficiency and dependability in industrial settings.

Achieving a Bubble-Tight Seal

A key performance indicator for any valve is its ability to prevent leaks. PTFE's flexibility and surface properties allow for a superior, bubble-tight seal when the valve is closed.

This high sealing performance is critical for safety, especially when handling toxic or hazardous media, and for preventing product loss.

Simple, Efficient Flow Control

Butterfly valves are known for their simple operating principle. A 90-degree turn of the stem moves the disc from fully open to fully closed.

This fast actuation speeds up processes and makes the valves easy to automate, reducing the need for manual operation by plant personnel.

Durability and Low Maintenance

By protecting the valve's core components, the PTFE lining significantly reduces wear and tear.

This inherent durability translates to minimal maintenance requirements and a lower total cost of ownership over the valve's lifespan.

Understanding the Trade-offs and Limitations

While highly effective, PTFE lined valves are not a universal solution. Understanding their limitations is key to proper application.

Pressure and Temperature Boundaries

The specified temperature limit of around 200°C (392°F) is a firm boundary. For applications involving high-temperature steam or fluids, you must consider high-performance butterfly valves or other designs made from specialized metal alloys.

Similarly, they are most cost-effective and suitable for low-to-moderate pressure applications. High-pressure systems may demand the robust construction of a ball or globe valve.

Not Ideal for Abrasive Slurries

While chemically inert, PTFE is a relatively soft material. It can be susceptible to erosion and damage from media containing abrasive particles or heavy slurries.

In these applications, a rubber-lined or specialized severe-service valve may be a more appropriate choice to prevent premature wear of the lining.

Making the Right Choice for Your Application

Selecting the correct valve requires matching its strengths to your specific operational goal.

- If your primary focus is handling highly corrosive media: The PTFE lining provides a chemically inert barrier, offering a cost-effective alternative to expensive alloy valves.

- If your primary focus is operational efficiency and low maintenance: The valve's simple design and durable lining reduce process downtime and long-term service requirements.

- If your primary focus is system safety and purity: The reliable, zero-leakage sealing capabilities protect personnel and prevent contamination of the process media.

- If your process involves high pressures or abrasive solids: You should evaluate other valve types specifically designed for those demanding conditions.

Ultimately, choosing a PTFE lined butterfly valve is a strategic decision for achieving reliable, long-term performance in challenging chemical environments.

Summary Table:

| Feature | Benefit | Typical Application |

|---|---|---|

| PTFE Lining | Superior chemical inertness against acids, bases, and solvents. | Chemical Processing, Pharmaceuticals |

| Wide Temp Range | Operates from -196°C to 200°C for cryogenic and high-temp processes. | Petrochemical, Industrial |

| Bubble-Tight Seal | Zero-leakage performance for safety and media purity. | Hazardous Material Handling |

| Low Maintenance | Durable design reduces wear and extends service life. | Water Treatment, General Industrial |

Need a reliable valve solution for corrosive or high-purity applications?

At KINTEK, we specialize in precision PTFE components, including custom-fabricated seals, liners, and labware. Our expertise ensures your valves and systems perform reliably in the most demanding environments, from semiconductors to pharmaceuticals.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision and durability to meet your exact specifications.

Contact KINTEK today to discuss your project requirements and discover the right PTFE solution for you.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the main benefits of PTFE slide bearings? A Low-Maintenance, High-Performance Alternative

- Why is Teflon particularly suitable for medical and food processing applications? Unmatched Purity & Performance

- What industries commonly use PTFE-lined plug valves and why? Ensure Safety and Purity in Demanding Applications

- What type of gasket is particularly suitable for industries dealing with hazardous chemicals? The Definitive Choice for Safety

- How does the quality of Teflon bearings compare to traditional bearings? Superior Performance in Harsh Environments

- What is the heat resistance capability of PTFE seals? Withstand -200°C to 260°C for Unmatched Reliability

- How are glass-filled PTFE rods applied in the automotive industry? Enhance Performance & Reliability

- What is another name for PTFE V Ring? It's Also Known as a Teflon V Ring