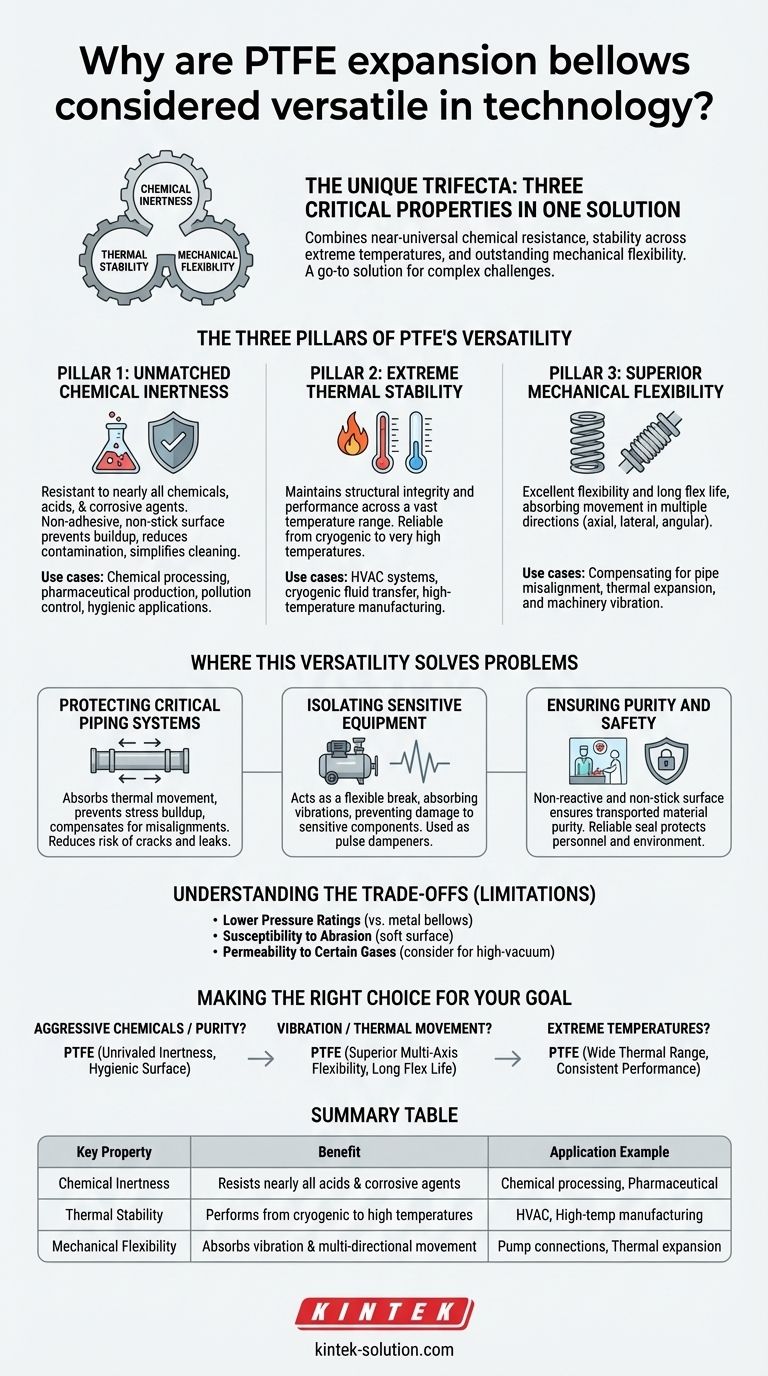

In short, PTFE expansion bellows are considered exceptionally versatile because they combine three critical properties that are rarely found together in a single material: near-universal chemical resistance, stability across extreme temperatures, and outstanding mechanical flexibility. This unique trifecta makes them a go-to solution for complex engineering challenges across dozens of industries.

The versatility of a PTFE bellow isn't about being a jack-of-all-trades; it's about being a master of several. It solves problems of chemical corrosion, thermal stress, and mechanical movement simultaneously, making it an indispensable component in demanding environments where other materials would quickly fail.

The Three Pillars of PTFE's Versatility

The performance of a PTFE expansion bellow can be traced back to three fundamental material characteristics. Understanding these pillars is key to appreciating why they are so widely adopted.

Pillar 1: Unmatched Chemical Inertness

PTFE is one of the most non-reactive substances known. It is resistant to nearly all chemicals, acids, and corrosive agents.

This extreme resistance makes it the ideal choice for piping systems that handle aggressive media in chemical processing, pharmaceutical production, and pollution control.

Furthermore, PTFE has a non-adhesive, non-stick surface. This property is critical in hygienic applications, as it prevents material buildup, reduces contamination risk, and simplifies cleaning procedures.

Pillar 2: Extreme Thermal Stability

PTFE bellows maintain their structural integrity and performance across a vast temperature range. They have a very high melting point and also remain flexible and durable at very low, cryogenic temperatures.

This allows them to be used reliably in systems that experience significant temperature fluctuations, from high-temperature manufacturing processes to HVAC and cryogenic fluid transfer.

Pillar 3: Superior Mechanical Flexibility

Expansion bellows are designed to move. PTFE's molecular structure gives it excellent flexibility and a long flex life, allowing it to absorb movement in multiple directions.

It effectively accommodates axial (compression/extension), lateral (sideways), and angular (bending) movements. This capability is vital for compensating for pipe misalignment, thermal expansion, and machinery vibration without transferring stress to the wider system.

Where This Versatility Solves Problems

The combination of these properties makes PTFE bellows a powerful problem-solver in several key areas.

Protecting Critical Piping Systems

Pipes naturally expand and contract with temperature changes. PTFE bellows absorb this movement, preventing stress buildup that could lead to cracks, leaks, or catastrophic failure in the piping.

They also compensate for minor misalignments between pipe sections or equipment, simplifying installation and reducing residual stress on flanges and connections.

Isolating Sensitive Equipment

Machinery like pumps and compressors generates constant vibration. A PTFE bellow acts as a flexible break in the line, absorbing these vibrations and preventing them from damaging more sensitive or rigid components downstream.

They are also used as pulse dampeners, smoothing out pressure fluctuations in a fluid system to protect delicate instruments and ensure consistent flow.

Ensuring Purity and Safety

In pharmaceutical and food processing, preventing contamination is paramount. The non-reactive and non-stick surface of PTFE ensures that the material being transported remains pure.

In applications involving dangerous chemicals or exhaust gases, the bellow's durability and chemical resistance provide a reliable seal, protecting personnel and the environment from hazardous leaks.

Understanding the Trade-offs

While incredibly versatile, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations.

Lower Pressure Ratings

Compared to their metal counterparts, PTFE expansion bellows generally have lower pressure resistance. They are not suitable for extremely high-pressure applications where a robust metallic bellow would be required.

Susceptibility to Abrasion

The surface of PTFE is relatively soft. In systems transporting abrasive slurries or materials with sharp particulates, the bellow can be subject to premature wear and damage.

Permeability to Certain Gases

While it is an excellent barrier, PTFE is not 100% impermeable to all small-molecule gases. In high-vacuum or specific gas-handling applications, this characteristic must be considered in the system design.

Making the Right Choice for Your Goal

To apply this knowledge, match the bellow's strengths to your primary engineering challenge.

- If your primary focus is handling aggressive chemicals or ensuring product purity: PTFE's unrivaled chemical inertness and hygienic surface make it the definitive choice.

- If your primary focus is absorbing vibration and thermal movement: The exceptional multi-axis flexibility and long flex life of PTFE provide superior protection for both equipment and piping.

- If your primary focus is operating in extreme temperatures: PTFE's wide thermal range ensures consistent, reliable performance where other elastomers would become brittle or degrade.

Ultimately, understanding the core properties of PTFE allows you to specify a component that not only fits but actively enhances the safety, longevity, and efficiency of your entire system.

Summary Table:

| Key Property | Benefit | Application Example |

|---|---|---|

| Chemical Inertness | Resists nearly all acids and corrosive agents | Chemical processing, pharmaceutical production |

| Thermal Stability | Performs from cryogenic to high temperatures | HVAC systems, high-temperature manufacturing |

| Mechanical Flexibility | Absorbs vibration and multi-directional movement | Pump/compressor connections, thermal expansion compensation |

Need a reliable solution for chemical, thermal, or mechanical challenges?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom expansion bellows, seals, liners, and labware. Our expertise ensures your systems in the semiconductor, medical, laboratory, and industrial sectors are protected against corrosion, extreme temperatures, and vibration.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact our experts today to discuss how our PTFE solutions can enhance the safety, longevity, and efficiency of your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- In which industries are Teflon seals commonly used? Essential for Chemical, Aerospace, and Medical

- Why are extruded PTFE rods popular in plumbing systems? Superior Chemical & Thermal Resistance

- What is the standard seat material for ball valves and why is it used? Discover the Ideal Choice for Your Application

- What are some common applications for hard PTFE grades? Solve High-Load, High-Wear Engineering Challenges

- What type of coolants are recommended for machining PTFE? Control Heat for Precision Results

- How does PTFE's chemical resistance contribute to its medical applications? Ensuring Biocompatibility and Sterilization Safety

- What benefits do spring energized Teflon seals provide? Unlock Reliable Sealing in Extreme Conditions

- What are the general advantages of using Teflon coating in industrial applications? Boost Efficiency & Protect Equipment