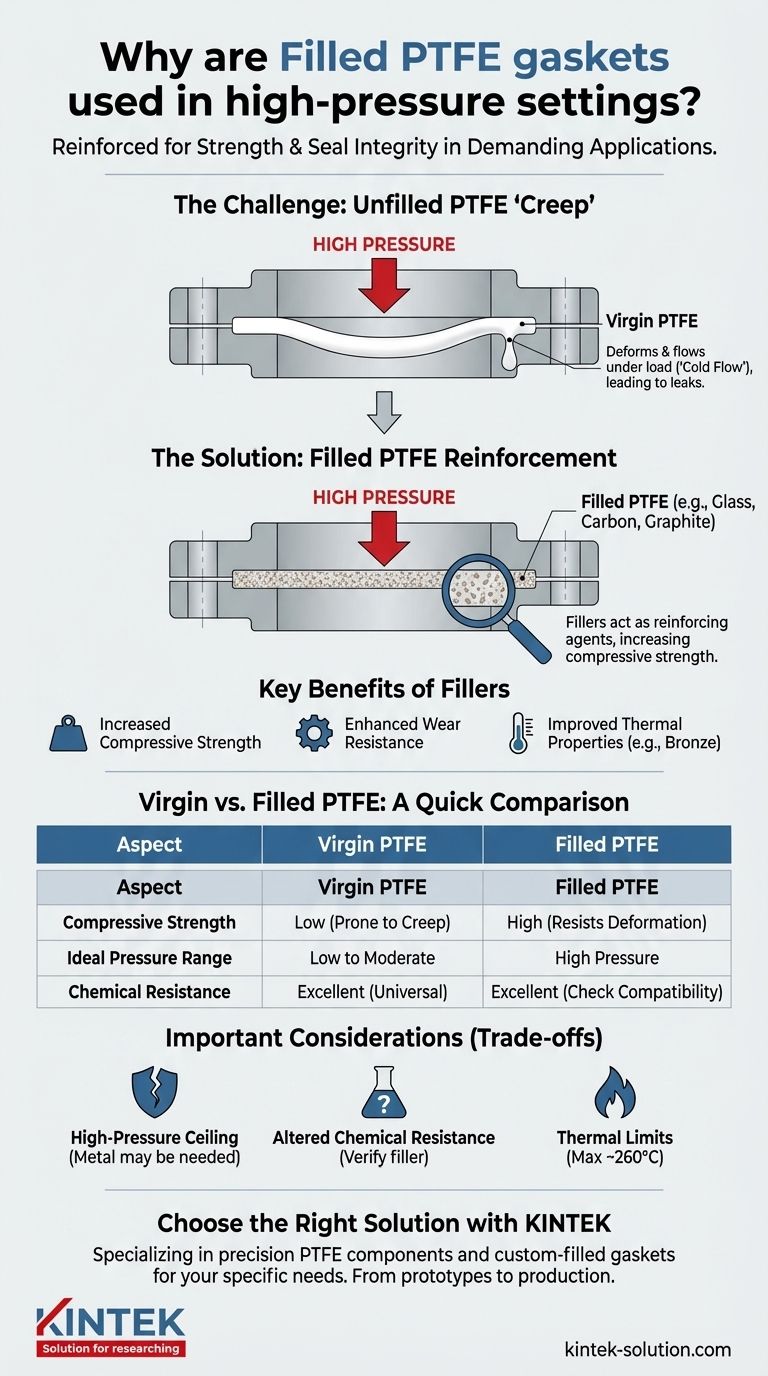

In high-pressure applications, the choice of sealing material is critical. Filled Polytetrafluoroethylene (PTFE) gaskets are used because adding fillers like glass, carbon, or graphite dramatically increases the material's strength and resistance to deformation. This reinforcement allows the gasket to withstand high mechanical loads and maintain a reliable seal under pressures that would cause standard, unfilled PTFE to fail.

While standard PTFE offers exceptional chemical resistance, it is a relatively soft material that can deform or "creep" under high pressure, leading to leaks. Adding fillers is the engineering solution that provides the necessary mechanical strength for high-pressure service without sacrificing PTFE's other valuable properties.

The Fundamental Problem with Unfilled PTFE

To understand the value of filled PTFE, you must first recognize the inherent limitations of the standard, or "virgin," material in mechanically demanding situations.

The Challenge of "Creep" and Cold Flow

Virgin PTFE is known for its softness and tendency to exhibit creep, also known as cold flow. This means that under a sustained compressive load, such as the clamping force from flange bolts, the material will slowly deform and flow out of the intended sealing area. This loss of material compromises the seal and inevitably leads to leaks, especially in high-pressure systems.

Limitations Under Mechanical Stress

This tendency to deform makes unfilled PTFE gaskets a poor choice for applications where high bolt loads are required to contain significant pressure. While excellent for low-pressure scenarios requiring elite chemical resistance, they lack the structural integrity to maintain a seal under intense mechanical stress.

How Fillers Transform PTFE's Performance

Adding a filler material to the PTFE base is a targeted strategy to overcome its mechanical weaknesses. The filler acts as a reinforcing agent within the polymer matrix.

Increasing Compressive Strength

Fillers like glass, carbon, and graphite add rigidity and structural support to the soft PTFE. This reinforcement drastically increases the material's compressive strength, making it far more resistant to the creep and cold flow that plague virgin PTFE. The gasket can now withstand higher flange loads without being squeezed out of place.

Enhancing Wear and Thermal Properties

Certain fillers provide additional benefits. Bronze-filled PTFE, for example, offers excellent thermal conductivity, helping to dissipate heat in applications with high temperatures or frequent start-stop cycles. This makes it well-suited for dynamic, high-pressure components like hydraulic piston rings.

Understanding the Trade-offs and Limitations

While highly effective, filled PTFE is not a universal solution. An objective evaluation requires acknowledging its limitations.

The High-Pressure Ceiling

Filled PTFE is a significant upgrade over virgin PTFE, but it still has a pressure limit. In applications involving extremely high pressures, metal gaskets are often the superior choice. Metal's inherent strength provides a level of mechanical integrity that even reinforced polymers cannot match.

Altered Chemical Resistance

The primary advantage of virgin PTFE is its near-universal chemical inertness. Introducing a filler can slightly compromise this. For example, glass-filled PTFE should not be used with strong alkalis or hydrofluoric acid, as these chemicals can attack the glass filler material. You must always verify that the specific filler is compatible with your process media.

The Thermal Breaking Point

PTFE has an upper-temperature limit (typically around 260°C or 500°F). While fillers can improve performance within this range, they do not prevent the base PTFE from breaking down if exposed to prolonged temperatures above its rating. In such cases, the gasket can degrade and fail.

Making the Right Choice for Your Application

Selecting the correct gasket material depends entirely on the specific demands of your system.

- If your primary focus is extreme chemical inertness at low-to-moderate pressure: Virgin (unfilled) PTFE is often the best and most cost-effective choice.

- If your primary focus is sealing a high-pressure or high-temperature system with aggressive chemicals: Filled PTFE provides the necessary mechanical strength and creep resistance that virgin PTFE lacks.

- If your primary focus is sealing extremely high pressures beyond PTFE's capabilities: You must evaluate metal or semi-metallic gaskets for their superior mechanical integrity.

Ultimately, choosing filled PTFE is an engineering decision to enhance the material's mechanical properties for demanding service environments.

Summary Table:

| Aspect | Virgin PTFE | Filled PTFE |

|---|---|---|

| Compressive Strength | Low (Prone to Creep) | High (Resists Deformation) |

| Ideal Pressure Range | Low to Moderate | High Pressure |

| Chemical Resistance | Excellent (Universal) | Excellent (Check Filler Compatibility) |

| Key Limitation | Fails under high load | Has a high-pressure ceiling |

Need a reliable seal for a high-pressure application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom-filled gaskets for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a component with the exact right filler and properties to handle your specific pressure, temperature, and chemical requirements—from prototypes to high-volume production.

Let us engineer a solution for you. Contact our experts today to discuss your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the benefits of using Teflon encapsulated silicone o-rings? Achieve Unmatched Sealing in Harsh Environments

- How does heat exposure affect PTFE seals? Mastering Thermal Expansion for Superior Sealing

- What are the recommended methods for preparing metal surfaces before bonding with PTFE? Achieve a Durable, High-Strength Bond

- What challenges are associated with CNC milling of PTFE? Overcome Softness and Thermal Expansion

- Why is PTFE sometimes etched and how is this process performed? Unlock Strong Bonding for Your PTFE Components

- How does PTFE perform against stainless steel in terms of friction? Discover Unmatched Low-Friction Performance

- What is Teflon AF and what are its optical properties? Achieve Superior Optical Clarity with UV Resistance

- What are the maintenance requirements for PTFE slide bearings? Ensure Long-Term, Maintenance-Free Performance