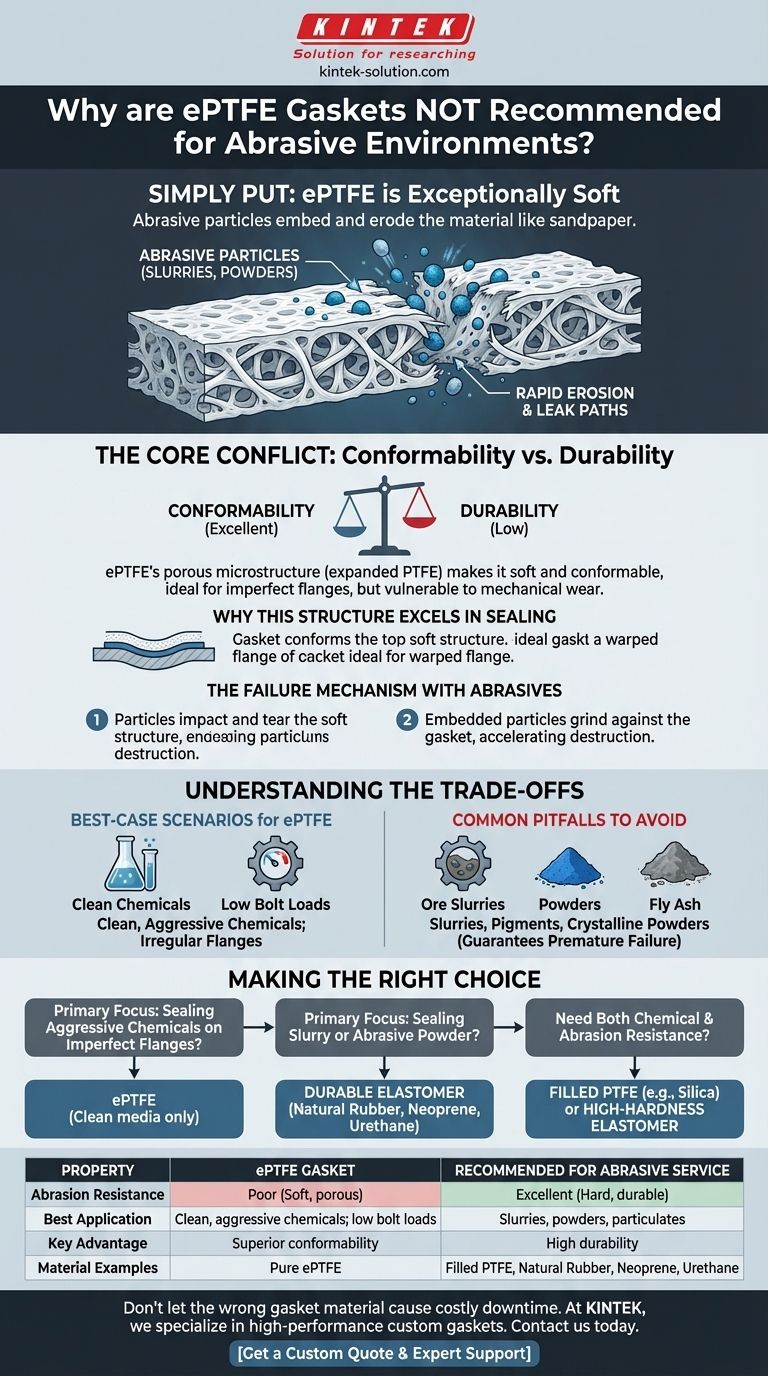

Simply put, expanded PTFE (ePTFE) gaskets fail in abrasive environments because the material is exceptionally soft. Abrasive particles in the process media, such as slurries or powders, easily embed into the gasket's surface and act like sandpaper, rapidly eroding the material and creating leak paths.

The very property that makes ePTFE an excellent sealant—its soft, conformable nature—is the precise reason for its vulnerability. Its porous microstructure is easily torn apart by abrasive forces, leading to a swift loss of seal integrity.

The Core Conflict: Conformability vs. Durability

The choice of a gasket material is always a balance of properties. For ePTFE, the central conflict is between its elite ability to conform to surfaces and its low physical durability.

Understanding ePTFE's Microstructure

Standard PTFE is a dense, slick plastic. To create ePTFE, this material is rapidly stretched, creating a highly fibrous and porous network of nodes and fibrils.

This expansion process introduces a significant amount of empty space into the material, making it incredibly soft and compressible compared to solid plastics or metals.

Why This Structure Excels in Sealing

The softness of ePTFE is its greatest strength in the right application. It allows the gasket to conform perfectly to flange surface imperfections, even with very low bolt loads.

This makes it an ideal choice for sealing delicate flanges, such as those made of glass, plastic, or those that are old, warped, or damaged. It creates a tight, reliable seal where harder materials would fail.

The Failure Mechanism with Abrasives

When a fluid containing abrasive particles flows past an ePTFE gasket, two things happen. First, the particles physically impact the soft fibrous structure, tearing it.

Second, particles become embedded within the gasket's porous surface. As the fluid continues to flow, these trapped particles grind against the gasket material, accelerating erosion and quickly destroying the sealing face.

Understanding the Trade-offs

Choosing a gasket is not about finding a "best" material, but the "right" material for the specific service conditions. Understanding where ePTFE shines and where it fails is critical.

Best-Case Scenarios for ePTFE

ePTFE remains a top-tier choice for applications involving aggressive chemicals (as it is chemically inert) where the media is clean and free of particulates.

It is also the go-to solution for low bolt-load applications or sealing irregular flange surfaces that require a highly conformable material.

Common Pitfalls to Avoid

Never specify ePTFE for services known to contain hard particulates. This includes applications like ore slurries, pigment and dye manufacturing, fly ash transport, or any process involving crystalline powders.

Using ePTFE in these environments guarantees premature failure, leading to leaks, costly downtime, and potential safety hazards. The material is simply not designed to withstand mechanical wear.

Making the Right Choice for Your Application

To prevent gasket failure, you must match the material's properties to the demands of the process. For abrasive service, this means prioritizing durability and resilience over conformability.

- If your primary focus is sealing aggressive chemicals on imperfect flanges: ePTFE is an excellent choice, but only if the media is clean and non-abrasive.

- If your primary focus is sealing a slurry or abrasive powder: Choose a durable elastomer like Natural Rubber, Neoprene, or a specialized urethane known for superior abrasion resistance.

- If you need both chemical resistance and abrasion resistance: Consider a filled PTFE gasket (with a filler like silica) or a high-hardness elastomer, and validate its performance for your specific media.

Selecting the correct gasket is fundamental to ensuring process reliability and safety.

Summary Table:

| Property | ePTFE Gasket | Recommended for Abrasive Service |

|---|---|---|

| Abrasion Resistance | Poor (Soft, porous structure) | Excellent (Hard, durable materials) |

| Best Application | Clean, aggressive chemicals; low bolt loads | Slurries, powders, processes with particulates |

| Key Advantage | Superior conformability to imperfect flanges | High durability and resilience to wear |

| Material Examples | Pure ePTFE | Filled PTFE, Natural Rubber, Neoprene, Urethane |

Don't let the wrong gasket material cause costly downtime.

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom gaskets engineered for your specific challenges. Whether you need a chemically inert ePTFE seal for a clean process or a durable, abrasion-resistant solution for harsh environments, our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a reliable, long-lasting seal.

Contact us today to discuss your application and let our precision production team deliver the perfect sealing solution for your semiconductor, medical, laboratory, or industrial needs.

Get a Custom Quote & Expert Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What makes PTFE extruded rods suitable for bearings and bushings? Discover Low-Friction, Maintenance-Free Performance

- How are PTFE lip seals used in the aerospace industry? Ensure Reliability in Extreme Conditions

- What are the overall advantages of using Teflon bushes in industrial settings? Achieve Maintenance-Free Reliability

- What are the key factors to consider when choosing a backup ring material? Ensure Seal Integrity in High-Pressure Systems

- What are the advantages of using PTFE in plain bearings? Achieve Maintenance-Free, High-Performance Operation

- How do PTFE valves perform under high temperatures? Unmatched Thermal Stability for Extreme Environments

- What materials are used in the manufacturing of PTFE ball valves? Optimize for Chemical Resistance & Performance

- What are the key features of PTFE gaskets? Unlock Superior Chemical & Thermal Sealing