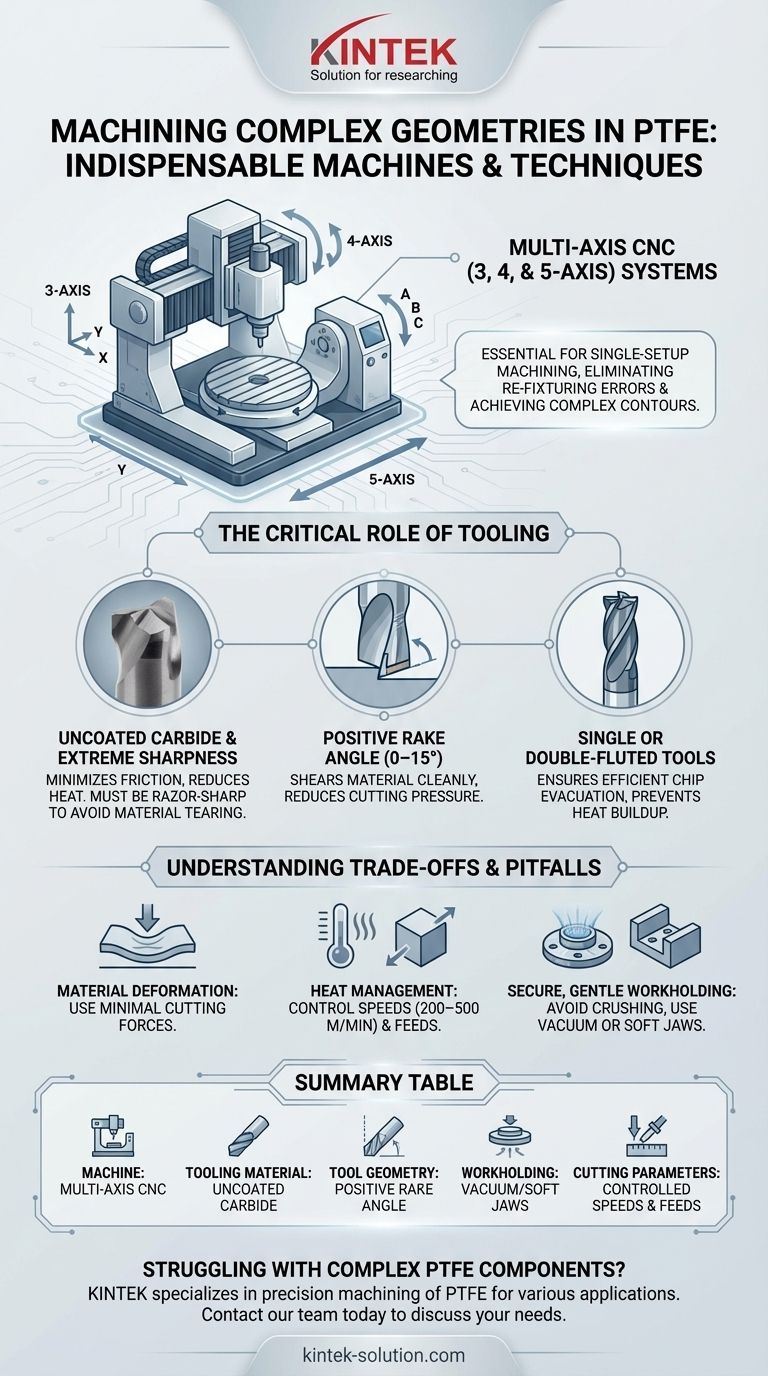

For machining complex geometries in PTFE, the indispensable machines are multi-axis (3, 4, and 5-axis) CNC (Computer Numerical Control) systems. These platforms are essential because they can manipulate the cutting tool and the workpiece along multiple axes simultaneously, enabling the creation of intricate features without repositioning the part, which is critical for maintaining accuracy.

Success in machining complex PTFE components is not solely dependent on the machine itself. It requires a complete system: a precise multi-axis CNC machine, extremely sharp tooling with specific geometry, and rigorous control over cutting parameters to manage the material's unique tendency to deform and expand with heat.

The Foundation: Why Multi-Axis CNC is Essential

Polytetrafluoroethylene (PTFE) is a notoriously soft, flexible material prone to deformation under pressure. When geometries become complex, the challenges multiply. Multi-axis CNC machines are the definitive solution to these challenges.

Eliminating Re-Fixturing Errors

Every time a part is unclamped and manually repositioned to machine a new face, the risk of dimensional error increases significantly.

Multi-axis machines can rotate and tilt the part or the tool, allowing access to five or even six sides of a component in a single setup. This single-setup machining is the key to achieving tight tolerances on complex parts.

Achieving Complex Contours and Angles

Features like curved surfaces, angled holes, and undercuts are nearly impossible to produce accurately on simpler machines.

A 5-axis CNC machine provides the toolpath flexibility needed to follow these complex contours smoothly and precisely, ensuring a high-quality surface finish and dimensional accuracy.

Ensuring Repeatability and Precision

CNC control systems execute programmed instructions with exceptional precision. For a material as sensitive as PTFE, this automated control is vital for maintaining consistent cutting forces and speeds, which prevents material stress and deformation across multiple parts.

Beyond the Machine: The Critical Role of Tooling

Choosing the right machine is only the first step. The interface between the machine and the material—the cutting tool—is equally critical for a successful outcome.

Material Choice: Carbide and HSS

Uncoated carbide tools are the most recommended option for machining PTFE. Their ability to hold an extremely sharp edge reduces cutting forces and minimizes friction.

High-Speed Steel (HSS) and Stellite-tipped tools are also viable, provided they are maintained with a razor-sharp, polished edge.

The Importance of Extreme Sharpness

Dull tools do not cut PTFE; they push and tear it. This creates burrs, introduces stress into the material, and leads to poor surface finish and dimensional instability.

Tools must be dedicated to machining PTFE and resharpened regularly to maintain a pristine cutting edge.

Tool Geometry: Rake Angles and Flutes

Tools with a positive top rake angle (typically 0–15 degrees) are ideal. This geometry creates a shearing action that cleanly removes material rather than plowing through it, significantly reducing cutting pressure.

Using single or double-fluted tools helps provide ample space for chip evacuation, preventing heat buildup.

Why Uncoated Tools Are Preferred

Coatings like Titanium Nitride (TiN) can increase the coefficient of friction when machining soft polymers like PTFE.

Uncoated, highly polished tools are superior because they minimize frictional heat, which is the primary cause of thermal expansion and subsequent part warping.

Understanding the Trade-offs and Pitfalls

Successfully machining PTFE requires a deep understanding of its limitations. Ignoring these factors will lead to failed parts, even with the best equipment.

The Problem of Material Deformation

PTFE's low stiffness means it will easily bend or compress under pressure from either the cutting tool or the clamping fixture.

This demands minimal cutting forces (achieved with sharp tools) and specialized workholding solutions.

Heat Management and Thermal Expansion

PTFE has a very high rate of thermal expansion. Even a small amount of heat generated during cutting can cause the material to expand, throwing off dimensions. Once cooled, the part will contract and may no longer be within tolerance.

This makes controlling cutting speeds and feeds (typically 200–500 m/min and 0.1–0.5 mm/rev) absolutely critical.

The Need for Secure, Gentle Workholding

Standard vise jaws will crush or distort a PTFE part. You must use methods that distribute clamping pressure evenly and gently.

Effective solutions include vacuum fixtures, collet systems, or custom soft jaws machined to fit the part's profile.

Making the Right Choice for Your Application

Your specific goals will determine the precise configuration you need.

- If your primary focus is ultimate precision on multi-faceted parts: A 5-axis CNC machine is non-negotiable to eliminate re-fixturing errors and create complex contours in a single operation.

- If your primary focus is minimizing material stress: Prioritize uncoated, razor-sharp carbide tools with a high positive rake angle and meticulously control your speeds and feeds to prevent heat buildup.

- If your primary focus is preventing part deformation: Invest in a proper workholding solution, such as a vacuum chuck or custom soft jaws, before you begin any cutting.

Ultimately, mastering complex PTFE machining is about controlling every variable to accommodate the material's sensitive nature.

Summary Table:

| Key Factor | Essential Requirement | Purpose |

|---|---|---|

| Machine Type | Multi-Axis (3, 4, 5-axis) CNC | Single-setup machining for complex contours and angles |

| Tooling Material | Uncoated Carbide Tools | Maintains sharpness, minimizes friction and heat |

| Tool Geometry | Positive Rake Angle (0-15°) | Shears material cleanly, reduces cutting pressure |

| Workholding | Vacuum Fixtures / Custom Soft Jaws | Distributes clamping pressure, prevents deformation |

| Cutting Parameters | Controlled Speeds (200-500 m/min) & Feeds | Manages heat buildup and thermal expansion |

Struggling with complex PTFE components? KINTEK specializes in precision machining of PTFE seals, liners, and labware for semiconductor, medical, and industrial applications. Our advanced multi-axis CNC systems and expert tooling selection ensure your complex geometries are machined to exact tolerations without deformation. Contact our team today to discuss your custom fabrication needs—from prototypes to high-volume production.

Visual Guide

Related Products

People Also Ask

- What are the recommended tools for CNC machining Teflon? Achieve Clean, Precise Cuts

- What are some specific applications of PTFE shovels in the laboratory? Ensure Sample Purity and Safety

- In which industries can PTFE be used due to its hygienic properties? Ensure Purity and Safety in Food, Pharma, and Medical

- Which industries commonly use PTFE materials? A Guide to High-Performance Polymer Applications

- What does PTFE stand for? The Science Behind the Super-Material