For machining PTFE, the right tooling is paramount. The most recommended tools are extremely sharp, uncoated carbide or high-speed steel (HSS) cutters. These tools are chosen specifically to slice the material cleanly, which minimizes frictional heat and material deformation—the two primary challenges when working with this unique polymer.

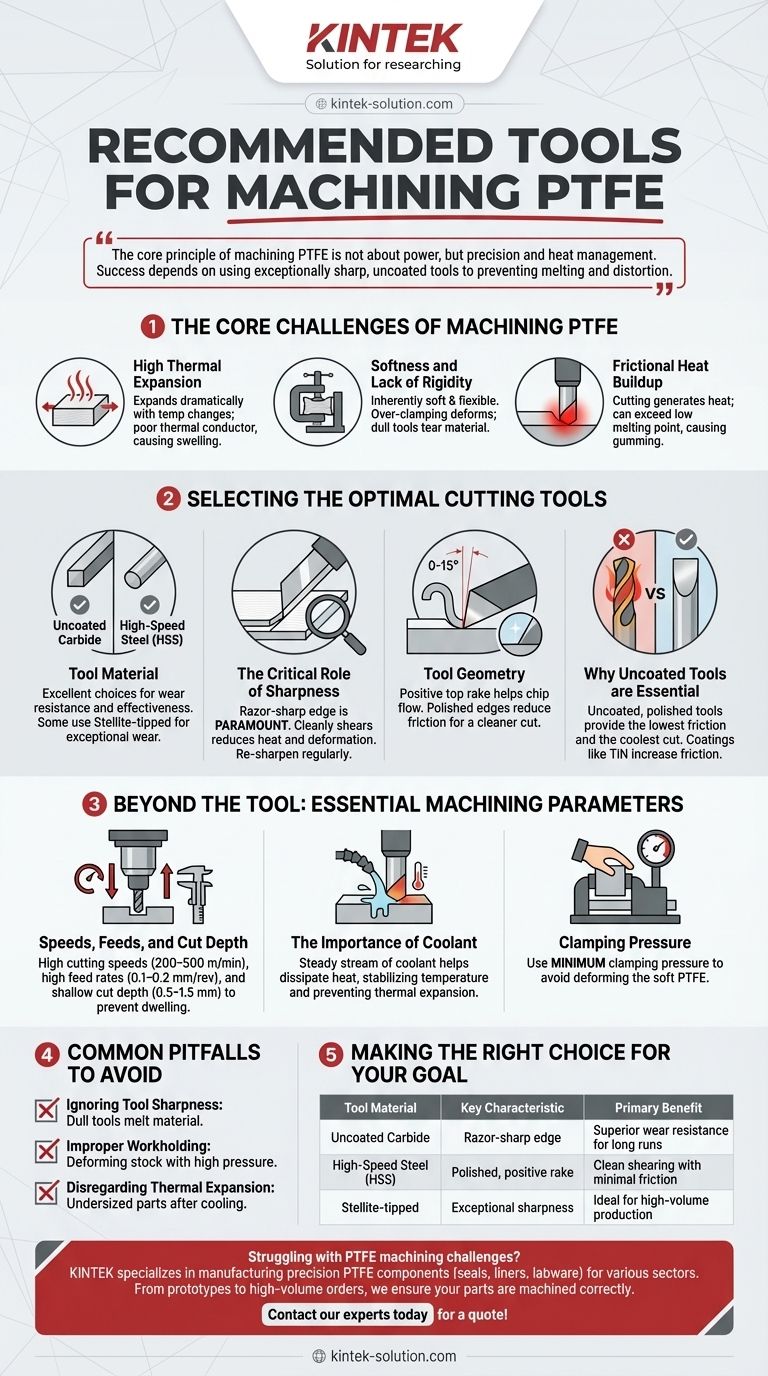

The core principle of machining Polytetrafluoroethylene (PTFE) is not about power, but precision and heat management. Success depends entirely on using exceptionally sharp, uncoated tools that cut the material with minimal pressure, preventing the melting and distortion that can easily ruin a workpiece.

The Core Challenges of Machining PTFE

To select the right tools, you must first understand why PTFE is notoriously difficult to machine. Its properties demand a specific approach that differs significantly from machining metals or even other plastics.

High Thermal Expansion

PTFE expands and contracts dramatically with temperature changes but is a poor thermal conductor. This means heat generated during cutting stays concentrated at the tool, causing the material to swell and leading to dimensional inaccuracies.

Softness and Lack of Rigidity

The material is inherently soft and flexible. Excessive clamping pressure in a vise will deform the workpiece, and a dull cutting tool will push or tear the material rather than shearing it cleanly.

Frictional Heat Buildup

Although known for its low coefficient of friction in sliding applications, the cutting process itself can generate significant heat. This heat can quickly exceed PTFE's low melting point, causing it to gum up on the tool and ruin the surface finish.

Selecting the Optimal Cutting Tools

Your tool selection is a direct response to the challenges above. Every choice is made to reduce forces and manage heat.

Tool Material: Carbide vs. HSS

Both uncoated carbide and high-speed steel (HSS) are excellent choices. Carbide offers superior wear resistance, making it ideal for longer production runs, while HSS is also highly effective. Some machinists also use Stellite-tipped tools for their exceptional wear resistance.

The Critical Role of Sharpness

A razor-sharp cutting edge is the single most important factor. A sharp tool cleanly shears the PTFE fibers with minimal pressure, significantly reducing both heat generation and material deformation. Tools must be re-sharpened regularly to maintain this edge.

Tool Geometry: Rake and Polished Edges

Tools with a positive top rake (often between 0 and 15 degrees) are highly recommended. This geometry helps curl the chip away from the workpiece and reduces the cutting forces required. Furthermore, polished edges on the tool reduce friction even further, contributing to a cleaner cut.

Why Uncoated Tools are Essential

This is often counterintuitive for machinists accustomed to modern coated tools. Coatings like Titanium Nitride (TiN) can actually increase friction when cutting PTFE, leading to more heat buildup. An uncoated, polished tool provides the lowest friction and the coolest cut.

Beyond the Tool: Essential Machining Parameters

The right tool is only effective when paired with the right process. Your machine settings must also be optimized for PTFE.

Speeds, Feeds, and Cut Depth

The goal is to remove material efficiently without letting the tool "dwell" and generate heat. This is often achieved with high cutting speeds (200–500 m/min) paired with high feed rates (0.1–0.2 mm/rev). A shallow depth of cut (0.5–1.5 mm) is also crucial to minimize stress on the material.

The Importance of Coolant

Using a coolant system is highly advisable. A steady stream of coolant helps dissipate heat at the point of the cut, stabilizing the material's temperature and preventing the thermal expansion that ruins tolerances.

Clamping Pressure

Always use the minimum clamping pressure necessary to hold the workpiece securely. Over-tightening the vise will compress the soft PTFE, causing the finished part to be out of specification once it is released and relaxes.

Common Pitfalls to Avoid

Mistakes in machining PTFE are common because its behavior is so different from other materials. Avoiding these pitfalls is critical for success.

Ignoring Tool Sharpness

The most common failure is using a tool that is even slightly dull. A dull tool immediately begins to push and melt the material instead of cutting it, resulting in a poor surface finish and incorrect dimensions.

Improper Workholding

Failing to account for PTFE's softness during setup is a frequent error. Custom fixtures or soft jaws that distribute clamping force are often necessary to avoid deforming the stock.

Disregarding Thermal Expansion

A part measured to be perfectly in-spec while it is still warm from machining will be undersized once it cools to ambient temperature. This effect must be anticipated and compensated for.

Making the Right Choice for Your Goal

Your tooling and process should align with your project's specific requirements.

- If your primary focus is high precision and tight tolerances: Prioritize exceptionally sharp, uncoated carbide tools and use a flood coolant system to meticulously manage thermal expansion.

- If your primary focus is high-volume production: Invest in carbide or Stellite-tipped tools for their superior wear resistance and establish a strict re-sharpening schedule to maintain consistent quality.

- If you are performing secondary operations like drilling or tapping: Use high feed rates and peck drilling cycles to clear chips effectively and prevent them from melting and binding in the hole.

Ultimately, success in machining PTFE comes from respecting its unique properties and choosing tools and techniques that prioritize finesse over force.

Summary Table:

| Tool Material | Key Characteristic | Primary Benefit |

|---|---|---|

| Uncoated Carbide | Razor-sharp edge | Superior wear resistance for long runs |

| High-Speed Steel (HSS) | Polished, positive rake | Clean shearing with minimal friction |

| Stellite-tipped | Exceptional sharpness | Ideal for high-volume production |

Struggling with PTFE machining challenges like heat deformation or poor surface finish? KINTEK specializes in manufacturing precision PTFE components (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your parts are machined correctly from the start, saving you time and material. Contact our experts today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems