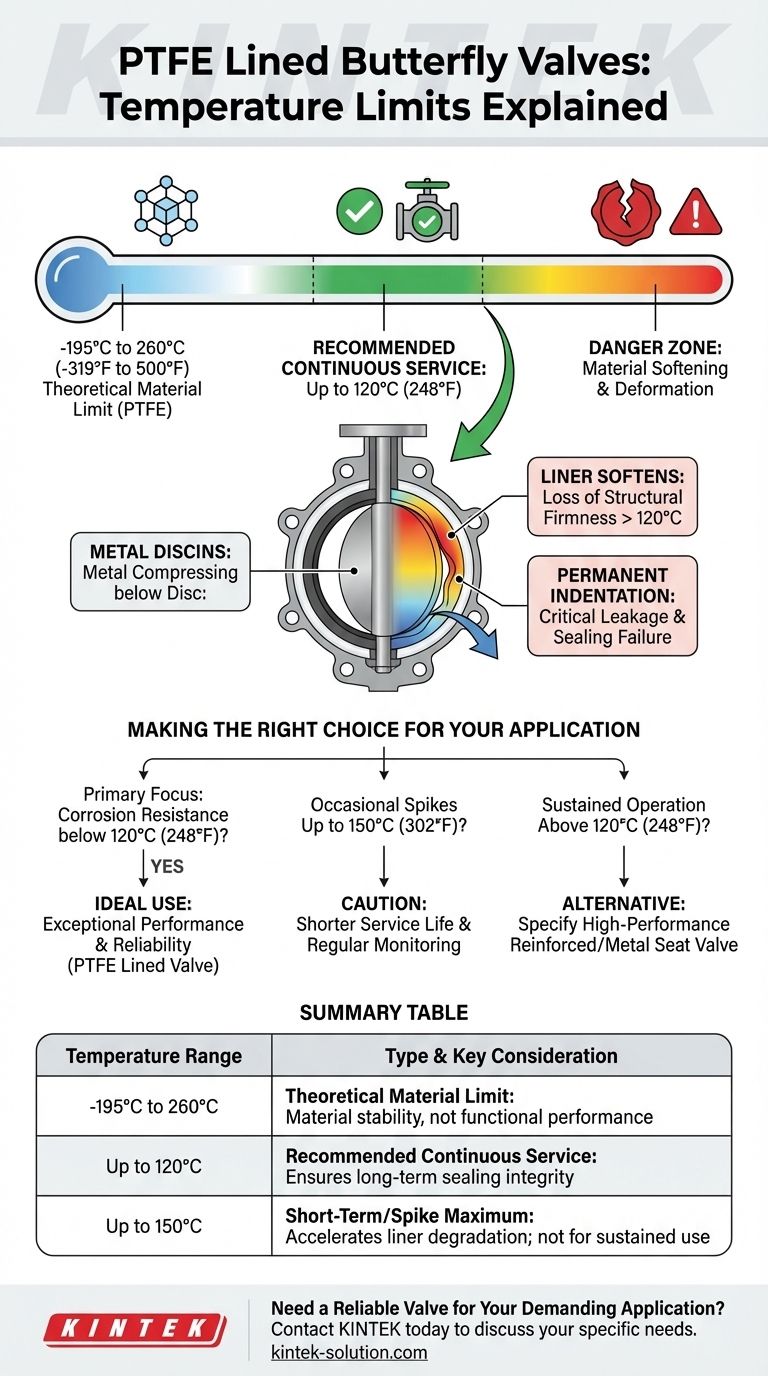

In principle, PTFE lined butterfly valves can operate within a theoretical temperature range as wide as -195°C to 260°C (-319°F to 500°F). However, the practical and safe operating limit for the media is significantly more constrained. For long-term reliability, the continuous service temperature should not exceed 120°C (248°F).

The core issue is the difference between the material's tolerance and the valve's mechanical function. While the PTFE material itself can withstand high temperatures, its role as a compressive seal in a butterfly valve means it will soften and deform at temperatures well below its theoretical maximum, leading to critical leakage.

Material Limits vs. Operational Reality

To select the right valve and ensure system safety, it's essential to understand why the advertised material temperature range differs so starkly from its practical application limit.

The Theoretical Tolerance of PTFE

Polytetrafluoroethylene (PTFE) is a remarkably stable polymer. As a raw material, it exhibits excellent thermal stability and chemical inertness across an extremely wide temperature spectrum.

This inherent material property is why some technical data sheets cite very high maximum temperatures, sometimes up to 260°C (500°F).

How Valve Design Imposes Constraints

A lined butterfly valve does not rely on the PTFE's material strength alone. It depends on its mechanical properties to create a seal.

The valve seals when the edge of the metal disc compresses into the softer PTFE liner. This action requires the liner to be firm enough to provide sealing pressure but flexible enough to deform and then return to its original shape.

The Critical Role of Media Temperature

The temperature of the fluid or gas (the media) passing through the valve is what dictates the liner's temperature.

When the media temperature rises, it heats the PTFE liner. As the liner approaches and exceeds 120°C (248°F), it begins to lose its structural firmness.

The Critical Trade-off: Performance vs. Temperature

Pushing a PTFE lined valve beyond its recommended operational temperature introduces significant and often irreversible risks.

Softening and Deformation

The primary failure mode is liner deformation. At sustained high temperatures, the PTFE softens to a point where the pressure from the valve disc creates a permanent indentation.

This is especially pronounced when the valve is left in a closed or partially closed position for extended periods at high temperatures.

Loss of Sealing Integrity

Once the liner is deformed, it can no longer create a uniform, tight seal around the disc when the valve is closed. This results in leakage, which can range from minor drips to a significant loss of containment.

The "Short-Term" vs. "Long-Term" Distinction

Some manufacturers specify a short-term maximum temperature, often around 150°C (302°F). This implies the valve can handle brief temperature spikes without immediate failure.

However, continuous operation at these elevated temperatures will inevitably accelerate liner degradation and drastically shorten the valve's service life. The safe, conservative limit for long-term use remains 120°C (248°F).

Making the Right Choice for Your Application

Use these guidelines to determine if a PTFE lined butterfly valve is appropriate for your specific process conditions.

- If your primary focus is corrosion resistance in processes below 120°C (248°F): This is the ideal use case for a PTFE lined valve, offering exceptional performance and reliability.

- If your process involves occasional temperature spikes up to 150°C (302°F): The valve may function, but you must accept a shorter service life and implement regular monitoring for seal leakage.

- If your primary focus is sustained operation at temperatures above 120°C (248°F): You must specify a different solution, such as a high-performance butterfly valve with a reinforced or metal seat.

- If your application is cryogenic (e.g., -50°C and below): PTFE is an excellent material for low-temperature service, but you must verify that the entire valve assembly, including the body and stem, is rated for your target temperature.

Ultimately, respecting the valve's operational temperature limit is the key to ensuring the long-term integrity and safety of your system.

Summary Table:

| Temperature Range | Type | Key Consideration |

|---|---|---|

| -195°C to 260°C (-319°F to 500°F) | Theoretical Material Limit (PTFE) | Material stability, not functional valve performance. |

| Up to 120°C (248°F) | Recommended Continuous Service | Ensures long-term sealing integrity and reliability. |

| Up to 150°C (302°F) | Short-Term/Spike Maximum | Accelerates liner degradation; not for sustained use. |

Need a Reliable Valve for Your Demanding Application?

Understanding the precise limits of your components is critical to system safety and performance. At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals and liners, for the semiconductor, medical, laboratory, and industrial sectors.

Whether you require a standard solution or a custom-fabricated component for prototypes or high-volume orders, our focus on precision production ensures you get a part that meets your exact operational requirements.

Contact KINTEK today to discuss your specific needs and ensure the integrity of your system.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What makes PTFE seals dimensionally stable? Engineered Rigidity for Demanding Seals

- What is the temperature range for expanded PTFE? From -400°F to 500°F for Extreme Environments

- What are the key takeaways when comparing FR4 and PTFE laminates? Choosing the Right PCB Material for Your Application

- How does the construction of PTFE-lined plug valves provide chemical resistance? Achieve Unmatched Corrosion Protection

- Why is PTFE the preferred material for bellows and diaphragms? Unmatched Chemical, Thermal, and Mechanical Stability

- What operating conditions are PTFE-lined plug valves particularly suitable for? Control Corrosive & High-Purity Fluids

- How does hydrothermal corrosion affect PTFE sliding bearings? Uncover the Two-Pronged Attack

- How does the PTFE lining in diaphragm valves enhance performance? Boost Reliability in Harsh Chemical Processes