In short, technical services for PTFE product development guide you through the entire lifecycle, from initial concept to a finished, manufactured component. These services include application analysis, material selection, product design, reverse engineering, and a range of custom fabrication methods like laser cutting, stamping, and die cutting.

The core purpose of these technical services is to ensure your final product is not just manufactured, but expertly engineered to leverage the unique properties of PTFE for optimal performance and longevity in its specific application.

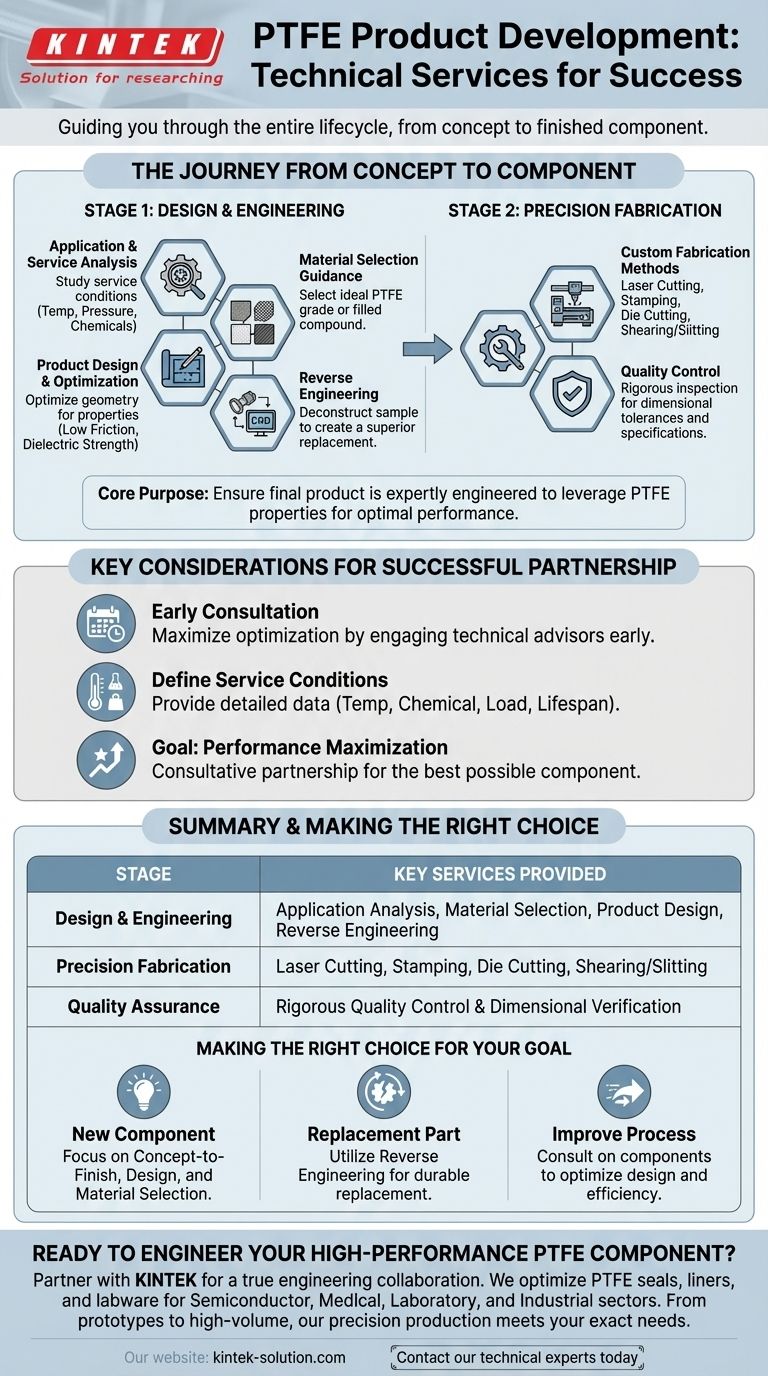

The Journey from Concept to Component

Successfully developing a PTFE product involves more than just fabrication. It requires a collaborative engineering process that begins long before any material is cut. This process ensures the final part is perfectly suited to its environment and function.

Stage 1: Design and Engineering

This initial phase is the most critical for defining the success of the final product. Expert guidance here prevents costly errors down the line.

Application and Service Analysis

Engineers first study the intended application in detail. They analyze the specific service conditions the part will face, such as operating temperature, pressure, chemical exposure, and mechanical stress.

Material Selection Guidance

Not all PTFE is the same. Based on the application analysis, specialists will guide you in selecting the ideal PTFE grade or a filled compound that enhances specific properties like wear resistance, compressive strength, or thermal conductivity.

Product Design and Optimization

With a material selected, the focus shifts to the part's physical design. Engineers help optimize the geometry to take full advantage of PTFE's attributes—like its low friction or dielectric strength—while ensuring it meets all functional requirements.

Reverse Engineering

If you have an existing part that needs to be replaced or improved, an in-house lab can perform reverse engineering. This process deconstructs a sample to determine its material composition and design, providing a blueprint for creating a superior replacement.

Stage 2: Precision Fabrication

Once the design is finalized and approved, the product moves to the manufacturing stage, where precision is paramount.

Custom Fabrication Methods

Advanced machinery is used to shape the PTFE material according to the exact design specifications. Key services include:

- Shearing/Slitting: Cutting PTFE films and sheets to precise widths.

- Laser Cutting: Using a high-powered laser for intricate and complex shapes with clean edges.

- Stamping & Die Cutting: Efficiently producing high volumes of identical parts by pressing a sharp die through the material.

Quality Control

Throughout the fabrication process, rigorous quality control measures are in place. This ensures every finished component meets the required dimensional tolerances and material specifications.

Key Considerations for a Successful Partnership

To get the most value from these technical services, it's important to understand your role in the process. The quality of the input you provide directly impacts the quality of the outcome.

The Importance of Early Consultation

Engaging with technical advisors at the very beginning of your design process maximizes the potential for optimization. Waiting until a design is already "locked in" limits the ability of engineers to suggest fundamental improvements that could enhance performance or reduce cost.

Clearly Define Your Service Conditions

Be prepared to provide detailed information about your application. The more data you can share about temperature ranges, chemical contact, load requirements, and desired lifespan, the more precisely the engineers can tailor the material and design to your needs.

Understand the Goal: Performance Maximization

The guiding principle of these services is to maximize the unique attributes of PTFE for your specific use case. This is a consultative partnership aimed at creating the best possible component, not just fulfilling a basic order.

Making the Right Choice for Your Goal

To best leverage these services, identify your primary objective.

- If your primary focus is developing a brand-new component: Engage experts for the full concept-to-finish service, paying close attention to the initial design and material selection stages.

- If your primary focus is replacing a failing or obsolete part: Utilize reverse engineering services to analyze the existing part and engineer a more durable, higher-performance replacement.

- If your primary focus is improving an existing manufacturing process: Consult on specific components like wear strips or heat sealing bands to optimize their design and material for better efficiency and longevity.

Ultimately, partnering with a technical advisor transforms the process from simple procurement into a strategic engineering collaboration.

Summary Table:

| Stage | Key Services Provided |

|---|---|

| Design & Engineering | Application Analysis, Material Selection, Product Design, Reverse Engineering |

| Precision Fabrication | Laser Cutting, Stamping, Die Cutting, Shearing/Slitting |

| Quality Assurance | Rigorous Quality Control & Dimensional Verification |

Ready to Engineer Your High-Performance PTFE Component?

Partner with KINTEK for a true engineering collaboration. We don't just manufacture parts; we provide the technical expertise to ensure your PTFE seals, liners, and labware are optimized for performance in the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, our precision production and custom fabrication services are designed to meet your exact needs.

Contact our technical experts today to discuss your project and maximize the potential of your PTFE application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What is the significance of PTFE's chemical inertness in instrumentation systems? Ensure Unmatched System Integrity and Accuracy

- What are the friction properties of extruded PTFE rods? Achieve Ultra-Low Friction for Your Critical Applications

- What are PTFE seals commonly known as? Discover Teflon® Seals for Extreme Performance

- Why are PTFE reducing flanges considered cost-effective? Maximize Uptime and Minimize Costs

- What are the properties of stainless steel-reinforced PTFE? A High-Performance Composite for Demanding Seals

- What are some key characteristics of Teflon and PTFE that make them suitable for building construction? Enable Durable, Low-Maintenance Structures

- Why are PTFE expansion bellows considered a cost-effective long-term investment? Reduce Total Cost of Ownership