In aerospace and defense, PTFE rotary shaft seals are indispensable components used in mission-critical systems like turbine engines, landing gear, and rocket propulsion. Their unique material properties allow them to function reliably under the extreme temperatures, high rotational speeds, and aggressive chemical environments that would cause conventional seals to fail.

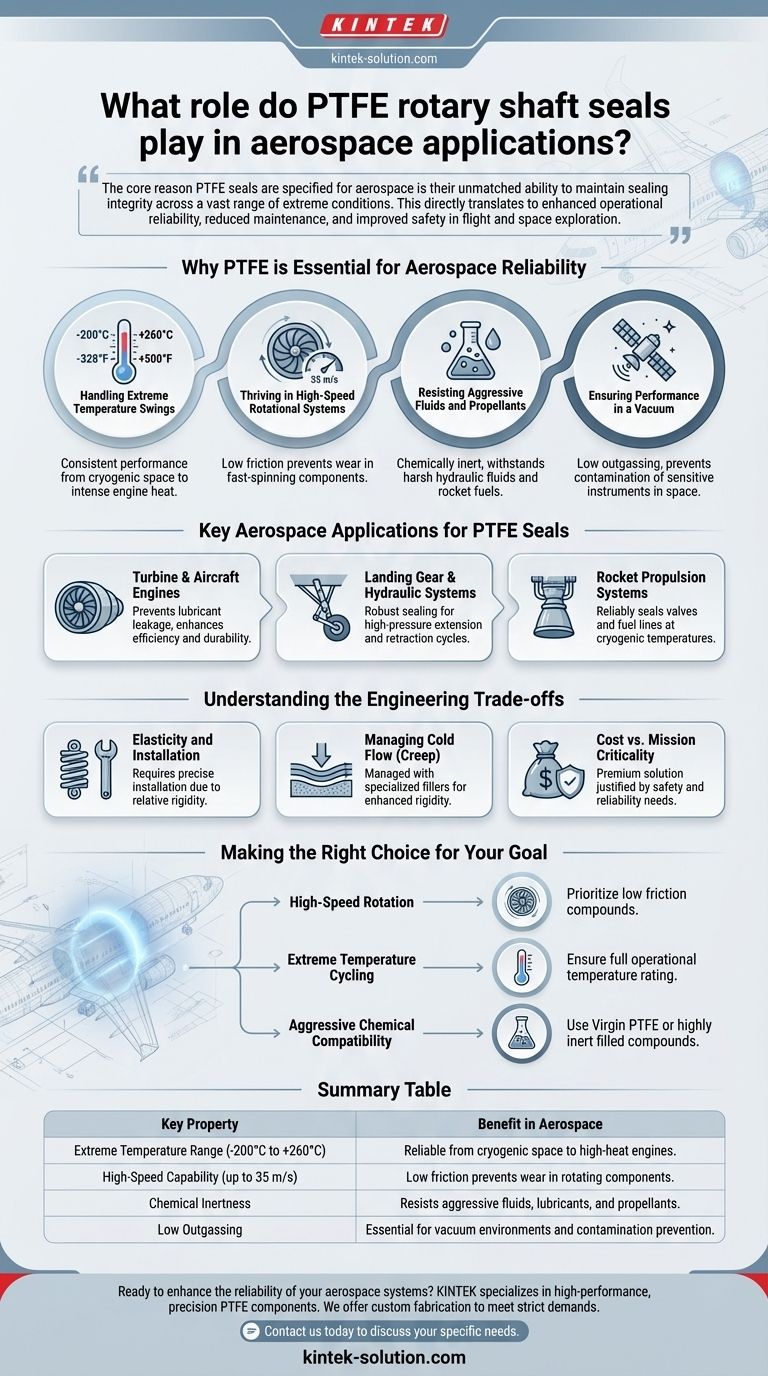

The core reason PTFE seals are specified for aerospace is their unmatched ability to maintain sealing integrity across a vast range of extreme conditions. This directly translates to enhanced operational reliability, reduced maintenance, and improved safety in flight and space exploration.

Why PTFE is Essential for Aerospace Reliability

The choice of a sealing material in aerospace is never arbitrary. It is a calculated decision based on performance under conditions that push materials to their absolute limits. PTFE (Polytetrafluoroethylene) possesses a unique combination of properties that make it an ideal solution.

Handling Extreme Temperature Swings

PTFE seals operate effectively within an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F). This allows them to perform consistently from the cold of high-altitude flight or deep space to the intense heat generated by engines and propulsion systems.

Thriving in High-Speed Rotational Systems

These seals are engineered for high-speed dynamics. They can handle shaft surface speeds up to 35 m/s without significant heat generation, thanks to PTFE's inherently low coefficient of friction. This prevents premature wear and failure in fast-spinning components like turbine engine shafts.

Resisting Aggressive Fluids and Propellants

Aerospace systems rely on aggressive hydraulic fluids, lubricants, and rocket propellants. PTFE is chemically inert, meaning it does not react with or degrade when exposed to these harsh substances, ensuring a long-lasting and reliable seal.

Ensuring Performance in a Vacuum

For space applications, materials must have low outgassing properties. This means they do not release trapped gasses when exposed to a vacuum, which is critical for preventing contamination of sensitive optical instruments, solar arrays, and other onboard electronics.

Key Aerospace Applications for PTFE Seals

The properties of PTFE seals make them the go-to choice for several critical systems where failure is not an option.

Turbine and Aircraft Engines

In engines, seals must withstand high rotational speeds and extreme temperatures. PTFE seals prevent lubricant leakage from bearing housings and gearboxes, contributing to engine efficiency and durability while reducing overall aircraft weight.

Landing Gear and Hydraulic Systems

Landing gear operation involves high-pressure hydraulic systems. PTFE seals provide the robust, chemically resistant sealing required to prevent fluid leaks under immense pressure during extension and retraction cycles.

Rocket Propulsion Systems

Rocket engines expose components to cryogenic temperatures and highly corrosive propellants. PTFE's chemical inertness and vast temperature range are essential for sealing valves and fuel delivery lines reliably.

Understanding the Engineering Trade-offs

While highly effective, specifying PTFE seals requires an understanding of their unique characteristics compared to traditional elastomeric (rubber) seals.

Elasticity and Installation

PTFE is a relatively rigid polymer and lacks the "memory" of rubber. This means seal design and installation procedures must be precise to ensure a proper fit and prevent damage during assembly.

Managing Cold Flow (Creep)

Under sustained pressure and temperature, PTFE can be susceptible to "cold flow," a slow deformation over time. This is effectively managed by seal manufacturers who use specialized fillers like carbon, glass, or bronze to create PTFE compounds with enhanced rigidity and creep resistance.

Cost vs. Mission Criticality

PTFE seals are a premium engineering solution. Their cost is higher than that of many conventional seals, but it is justified by the immense cost of component failure, maintenance downtime, and the paramount importance of safety in aerospace applications.

Making the Right Choice for Your Goal

Selecting the correct seal variant depends entirely on the primary challenge of the application.

- If your primary focus is high-speed rotation (e.g., turbines): Prioritize a PTFE compound designed for low friction to minimize heat generation and wear.

- If your primary focus is extreme temperature cycling (e.g., space vehicles): Ensure the selected PTFE grade is rated for the full operational temperature range, from cryogenic lows to peak operational highs.

- If your primary focus is aggressive chemical compatibility (e.g., propulsion systems): Virgin PTFE or a highly inert filled compound is essential to prevent seal degradation from fuels and oxidizers.

Ultimately, specifying a PTFE rotary shaft seal is an investment in the reliability and safety of the entire aerospace system.

Summary Table:

| Key Property | Benefit in Aerospace |

|---|---|

| Extreme Temperature Range (-200°C to +260°C) | Reliable performance from cryogenic space environments to high-heat engine systems. |

| High-Speed Capability (up to 35 m/s) | Low friction prevents wear in turbine engines and other high-speed rotating components. |

| Chemical Inertness | Resists degradation from aggressive hydraulic fluids, lubricants, and rocket propellants. |

| Low Outgassing | Essential for vacuum environments in space applications to prevent instrument contamination. |

Ready to enhance the reliability of your aerospace systems? KINTEK specializes in manufacturing high-performance, precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, industrial, and aerospace industries. We offer custom fabrication from prototypes to high-volume orders, ensuring your components meet the strict demands of extreme environments. Contact us today to discuss your specific needs and leverage our expertise for your mission-critical applications!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining