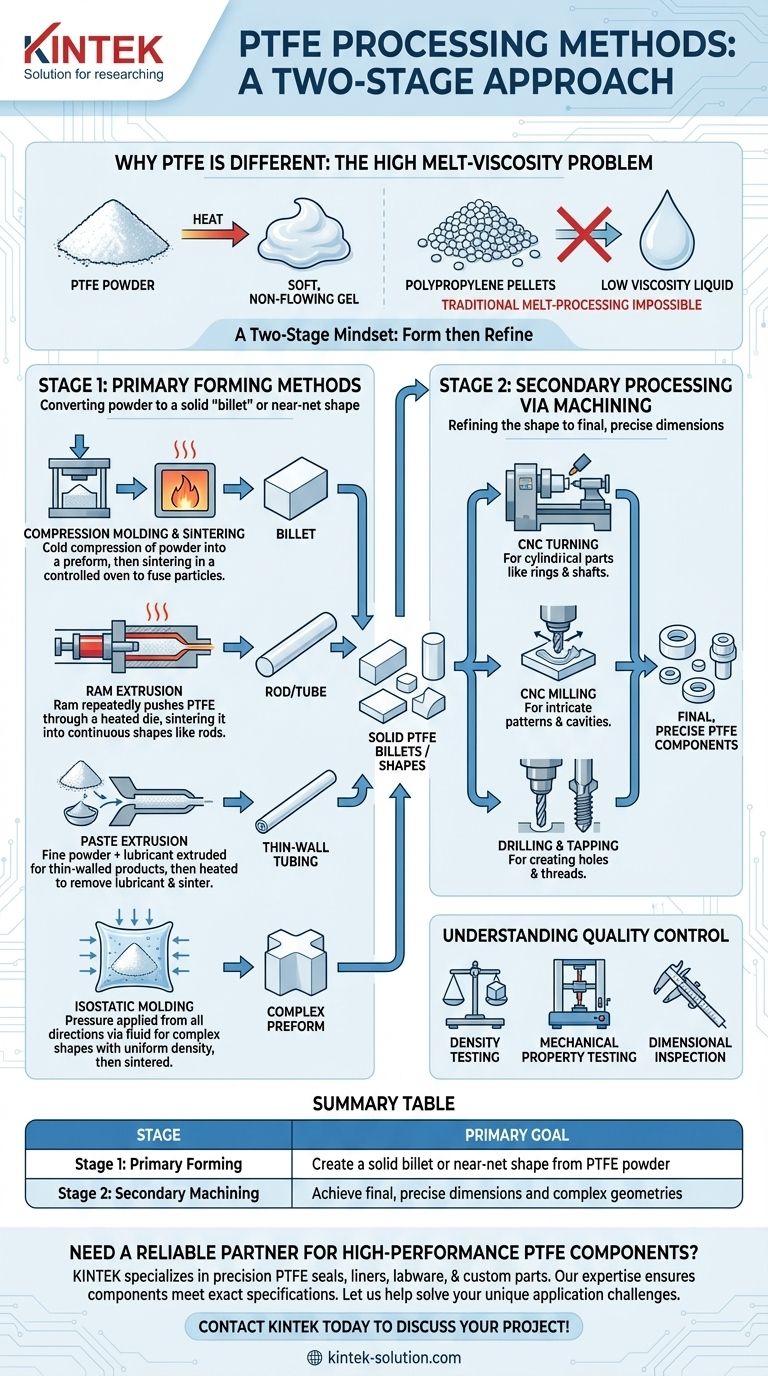

The typical processing methods for Polytetrafluoroethylene (PTFE) involve a two-stage approach. Unlike common thermoplastics, PTFE does not melt into a liquid state that can be easily injected or molded. Instead, it is typically processed using methods like compression molding and sintering to create a solid block or near-net shape, which is then often machined to achieve its final, precise dimensions.

The core challenge with PTFE is its extremely high melt viscosity; it becomes a soft, non-flowing gel rather than a liquid when heated. This fundamental property makes traditional melt-processing techniques like injection molding impossible and necessitates a unique combination of powder metallurgy and machining techniques.

Why PTFE Processing is Different

The High Melt-Viscosity Problem

PTFE resin does not flow when it melts. This behavior is the single most important factor dictating how it must be handled.

This is fundamentally different from plastics like polypropylene or ABS, which can be melted to a low viscosity and easily injected into a mold to create complex parts in a single step.

A Two-Stage Mindset: Form then Refine

Because it cannot be melt-processed, working with PTFE is best understood as a two-stage process. The first stage creates a solid, basic shape from powder, and the second stage refines that shape into the final component.

Stage 1: Primary Forming Methods

These methods are used to convert raw PTFE powder into a solid, fused part known as a "billet" or a near-net shape.

Compression Molding and Sintering

This is the most common method. Cold compression is used to press PTFE resin powder into the desired shape at room temperature. The resulting "preform" is then heated in a controlled oven in a process called sintering, where the PTFE particles fuse together into a solid mass.

RAM Extrusion

For creating continuous, uniform shapes like rods and tubes, RAM extrusion is used. A hydraulic ram repeatedly pushes small charges of PTFE powder through a heated die, sintering the material as it moves along to form a consistent profile.

Paste Extrusion

This method is used for creating thin-walled products, like wire insulation or tubing. It uses a fine powder PTFE (produced by dispersion polymerization) mixed with a lubricant, which is then extruded and heated to remove the lubricant and sinter the PTFE.

Isostatic Molding

For more complex shapes, isostatic molding applies pressure to PTFE powder from all directions simultaneously using a fluid medium. This creates a preform with very uniform density, which is then sintered.

Stage 2: Secondary Processing via Machining

Once a solid PTFE billet or shape has been formed and sintered, it is often refined to its final dimensions through machining.

The Role of CNC Machining

PTFE is remarkably easy to machine on standard equipment, including advanced CNC machines. This allows for the creation of highly complex and precise parts from a simple molded billet.

Key Machining Techniques

Standard tooling can be used for most operations. The most common techniques include CNC turning for cylindrical parts like rings and shafts, CNC milling for intricate patterns and cavities, and drilling and tapping for creating holes and threads.

Understanding the Trade-offs and Quality Control

The Critical Sintering Cycle

The success of any primary forming method hinges on the sintering cycle. The rates of heating, the time spent at the peak temperature, and the cooling rate all have a profound impact on the final part's density, mechanical strength, and dimensional stability.

Machinability vs. Final Finish

While PTFE is easy to machine, its softness means that achieving a perfectly smooth, burr-free finish requires sharp tools and specific techniques. For example, milling is effective but can create rougher edges if not performed carefully.

Verifying Part Quality

Due to its unique processing, rigorous quality control is essential. Key checks include density testing to ensure proper sintering, mechanical property testing (tensile and wear) to confirm performance, and dimensional inspection to verify accuracy against specifications.

Making the Right Choice for Your Application

Understanding the goal of your component is the key to selecting the appropriate process.

- If your primary focus is producing standard shapes (like rods or sheets) for machining: RAM extrusion and compression molding are the most efficient methods for creating stock material.

- If your primary focus is creating complex, high-precision parts: A two-stage process of molding a billet followed by CNC machining offers the most design freedom and accuracy.

- If your primary focus is manufacturing high volumes of a simple, repeatable shape (like a seal): Automatic compression molding can produce near-net shapes that require minimal or no secondary machining.

- If your primary focus is creating thin-walled tubing or coatings: Paste extrusion and other dispersion-based methods are the only viable options.

Mastering PTFE requires embracing its unique properties, where the journey from powder to finished part is a deliberate, multi-step process.

Summary Table:

| Stage | Key Methods | Primary Goal |

|---|---|---|

| Stage 1: Primary Forming | Compression Molding, RAM Extrusion, Paste Extrusion | Create a solid billet or near-net shape from PTFE powder. |

| Stage 2: Secondary Machining | CNC Turning, CNC Milling, Drilling | Achieve final, precise dimensions and complex geometries. |

Need a reliable partner for your high-performance PTFE components?

KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom parts for the semiconductor, medical, and industrial sectors. Our expertise in both primary forming and secondary machining ensures your components meet exact specifications for performance and durability.

We manage the entire process—from material selection and prototyping to high-volume production—guaranteeing quality and consistency. Let us help you solve your unique application challenges.

Contact KINTEK today to discuss your project and request a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry