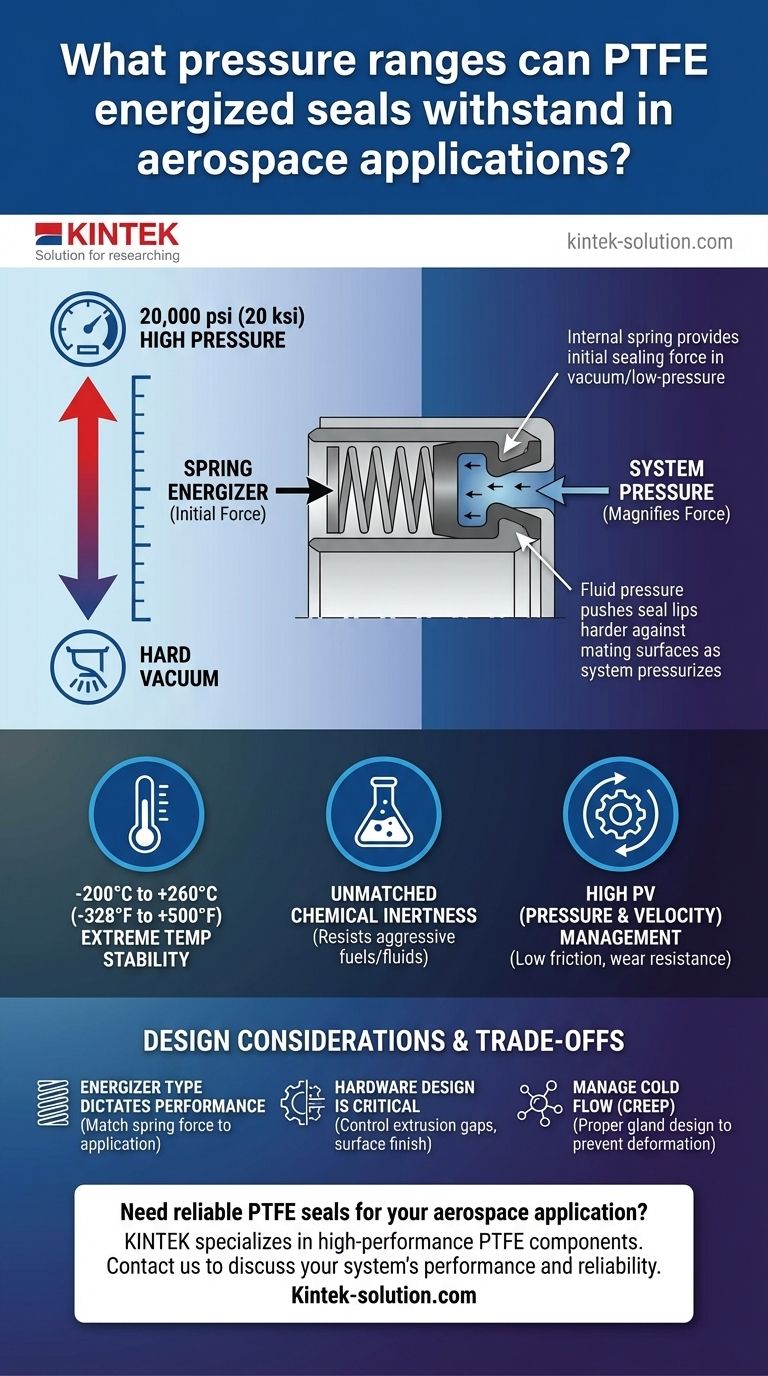

In aerospace applications, PTFE energized seals are engineered to operate across an exceptionally wide pressure spectrum, reliably sealing everything from a hard vacuum to pressures as high as 20,000 psi (20 ksi). This performance is achieved through a combination of PTFE's material properties and the mechanical design of the seal itself, where a spring energizer and system pressure work in concert.

A PTFE seal's pressure rating is not just a property of the material, but a function of the entire sealing system. The design leverages system pressure to increase sealing force, while the inherent properties of PTFE—compressive strength, low friction, and wide temperature tolerance—allow the system to function under extreme conditions.

How an Energized Seal Achieves Its Range

The genius of the energized seal lies in its two-part sealing mechanism. Understanding this is key to trusting its performance in critical systems from actuators to fuel pumps.

The Role of the Spring Energizer

The internal spring provides the initial sealing force when the system is unpressurized. This is what allows the seal to function effectively in vacuum or very low-pressure environments, creating a tight, positive seal where a simple O-ring might fail.

Using System Pressure as an Advantage

Once the system is pressurized, that pressure enters the seal cavity and acts upon the PTFE jacket. This fluid pressure magnifies the force exerted by the spring, pushing the seal lips harder against the mating surfaces. In essence, the higher the system pressure, the tighter the seal becomes.

The Material's Contribution

PTFE's high compressive strength prevents the seal from being crushed under load. Its extremely low coefficient of friction ensures it does not stick or wear excessively in dynamic applications, even under thousands of psi.

Beyond Pressure: Critical Factors for Aerospace

Pressure tolerance alone is not enough for a seal to qualify for aerospace use. PTFE's unique combination of properties makes it suitable for the punishing environments of engines, fuel systems, and flight controls.

Extreme Temperature Stability

PTFE seals maintain their integrity and performance across a vast temperature range, typically from cryogenic lows of -200°C (-328°F) up to high-temperature peaks of +260°C (+500°F). Elastomers simply cannot function at these extremes.

Unmatched Chemical Inertness

Used in hydraulic systems, fuel pumps, and engines, these seals must withstand aggressive fluids. PTFE is virtually inert to all common aerospace fuels, oils, and hydraulic fluids, preventing chemical degradation that would cause other materials to swell, shrink, or fail.

Managing High Pressure and Velocity (PV)

In dynamic applications like actuators or pumps, a seal experiences both pressure (P) and surface velocity (V). The "PV factor" is a critical limit for a seal material. Special blends of PTFE, often with fillers like carbon or glass, are engineered to handle high PV ratings, managing friction and wear far better than other polymers.

Understanding the Trade-offs and Design Considerations

While incredibly capable, a PTFE energized seal is not a drop-in solution. Its performance is directly tied to the design of the hardware it is installed in.

The Energizer Dictates Performance

The type of spring energizer used (e.g., V-spring, helical ribbon, cantilever) significantly impacts the sealing force. A high-force spring is ideal for static, high-pressure gas sealing, but it may create excessive friction and wear in a dynamic application. The choice must match the goal.

Hardware Design is Non-Negotiable

The seal is only one part of the system. Mating surface hardness and finish are critical for seal life. Most importantly, the extrusion gap—the clearance between moving parts—must be tightly controlled. At high pressures, even a robust PTFE jacket can be forced into an excessive gap, leading to premature failure.

Acknowledging Cold Flow (Creep)

PTFE's primary weakness is a tendency to "cold flow" or creep under a sustained load. While fillers in modern PTFE blends drastically reduce this, it remains a design consideration. The seal gland must be designed to properly support the seal and prevent unwanted material deformation over time.

Making the Right Choice for Your Application

Selecting the correct seal configuration requires a systems-level approach that balances pressure, temperature, motion, and hardware design.

- If your primary focus is high-pressure dynamic systems (e.g., flight control actuators): Prioritize a high-PV PTFE blend and ensure your hardware design maintains minimal extrusion gaps.

- If your primary focus is static cryogenic or high-temperature sealing (e.g., engine fuel connections): The material selection for both the PTFE jacket and the spring energizer is paramount for thermal stability.

- If your primary focus is vacuum or low-pressure sealing (e.g., environmental seals in an APU): The design and force of the spring energizer are the most critical factors for ensuring a consistent and reliable seal.

Ultimately, achieving reliable sealing in aerospace is about matching the right seal design and materials to the specific demands of the hardware and operating environment.

Summary Table:

| Pressure Range | Temperature Range | Key Capabilities |

|---|---|---|

| Vacuum to 20,000 PSI | -200°C to +260°C | High PV resistance, chemical inertness, low friction |

Need reliable PTFE seals for your aerospace application? KINTEK specializes in manufacturing high-performance PTFE components (seals, liners, labware) for the semiconductor, medical, laboratory, and industrial sectors. We offer precision production and custom fabrication from prototypes to high-volume orders to meet your exact specifications. Contact us today to discuss how our PTFE solutions can enhance your system's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection