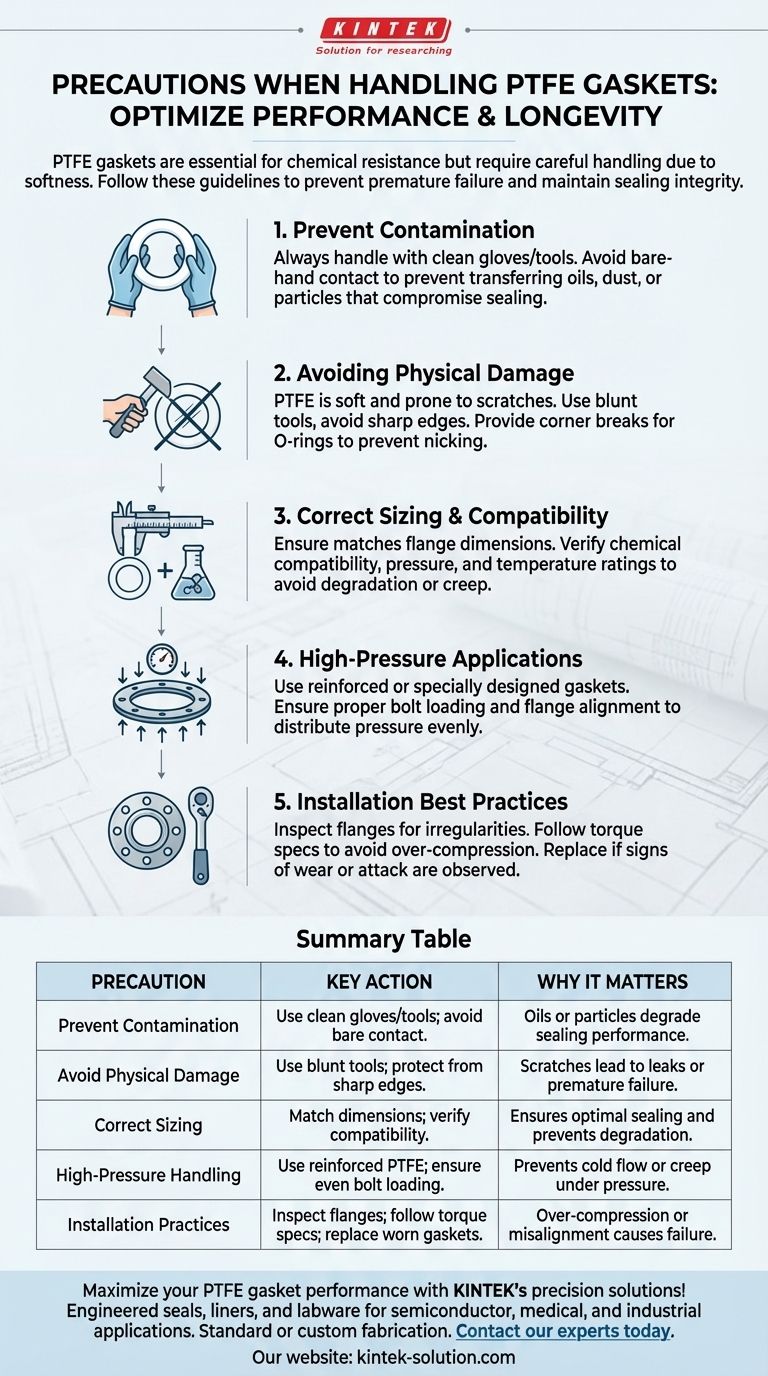

PTFE gaskets are widely used in industrial applications due to their excellent chemical resistance and sealing properties. However, their softness and susceptibility to damage require careful handling and installation to ensure optimal performance and longevity. Key precautions include using clean gloves or tools to prevent contamination, avoiding sharp edges that can scratch the surface, and ensuring proper sizing and compatibility for the intended application. Special attention is needed in high-pressure scenarios where deformation risks are higher. Following these guidelines minimizes premature failure and maintains sealing integrity.

Key Points Explained:

-

Preventing Contamination

- Always handle ptfe gaskets for flanges with clean gloves or tools to avoid transferring oils, dust, or particles.

- Bare hands can introduce contaminants that compromise the gasket's sealing ability or chemical resistance.

-

Avoiding Physical Damage

- PTFE is soft and prone to scratches, which can lead to leaks or premature failure.

- Use blunt tools and avoid sharp edges during installation or removal.

- For O-rings, provide corner breaks or guiding tools to prevent nicking during assembly.

-

Correct Sizing and Compatibility

- Ensure the gasket matches the flange dimensions and system requirements.

- Verify chemical compatibility with the media being sealed to avoid degradation.

- Check pressure and temperature ratings to prevent deformation or creep.

-

High-Pressure Applications

- PTFE's softness makes it susceptible to cold flow and creep under pressure.

- Use reinforced or specially designed PTFE gaskets for high-pressure systems.

- Ensure proper bolt loading and flange alignment to distribute pressure evenly.

-

Installation Best Practices

- Inspect flanges for burrs or irregularities that could damage the gasket.

- Follow torque specifications to avoid over-compression, which can cause cold flow.

- Replace gaskets if signs of wear, deformation, or chemical attack are observed.

By addressing these factors, users can maximize the lifespan and reliability of PTFE gaskets while minimizing downtime and maintenance costs. Have you considered how environmental factors like temperature fluctuations might further influence your gasket selection?

Summary Table:

| Precaution | Key Action | Why It Matters |

|---|---|---|

| Prevent Contamination | Use clean gloves/tools; avoid bare-hand contact. | Oils or particles degrade sealing performance. |

| Avoid Physical Damage | Use blunt tools; protect from sharp edges. | Scratches lead to leaks or premature failure. |

| Correct Sizing | Match flange dimensions; verify chemical/pressure compatibility. | Ensures optimal sealing and prevents degradation. |

| High-Pressure Handling | Use reinforced PTFE; ensure even bolt loading. | Prevents cold flow or creep under pressure. |

| Installation Practices | Inspect flanges; follow torque specs; replace worn gaskets. | Over-compression or misalignment causes failure. |

Maximize your PTFE gasket performance with KINTEK’s precision solutions!

Our PTFE components—including seals, liners, and labware—are engineered for semiconductor, medical, and industrial applications. Whether you need standard or custom fabrication, we ensure durability and chemical resistance. Contact our experts today to discuss your project needs or request a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why are PTFE seats preferred in electric actuated butterfly valves? Enhance Valve Performance and Actuator Lifespan

- How should application-specific temperature requirements be assessed for seal selection? Avoid Failure with a Complete Thermal Profile

- Which type of PTFE backup ring is better for harsh environments? Choose Spiral Rings for Maximum Reliability

- What are the characteristics of Polytetrafluoroethylene (PTFE) with Carbon-Graphite Fill for aqueous fluid media? Enhance Sealing Performance

- What are Labyrinth PTFE Seals and Bearing Isolators? Zero-Friction Sealing for High-Speed Equipment

- Why do PTFE gaskets have a long service life? Achieve Unmatched Sealing Durability & Cost Savings

- How do PTFE slide bearings accommodate thermal and seismic movements? Control Structural Movement with Low-Friction Design

- What benefits do PTFE lined pipes offer in terms of chemical flow? Ensure Corrosion-Free, High-Purity Transfer