Effectively machining Polytetrafluoroethylene (PTFE) requires a specific strategy focused on three key areas: using exceptionally sharp tooling with specific geometry, managing heat with high feed rates and effective coolants, and ensuring proper chip evacuation. Because PTFE is soft, has a low melting point, and is a poor thermal conductor, conventional machining methods often fail, leading to melted material, poor tolerances, and damaged tools.

The core challenge of machining PTFE is not its hardness, but its thermal properties. Success depends entirely on a strategy that minimizes friction and rapidly removes heat from the cutting zone to prevent the material from melting and deforming.

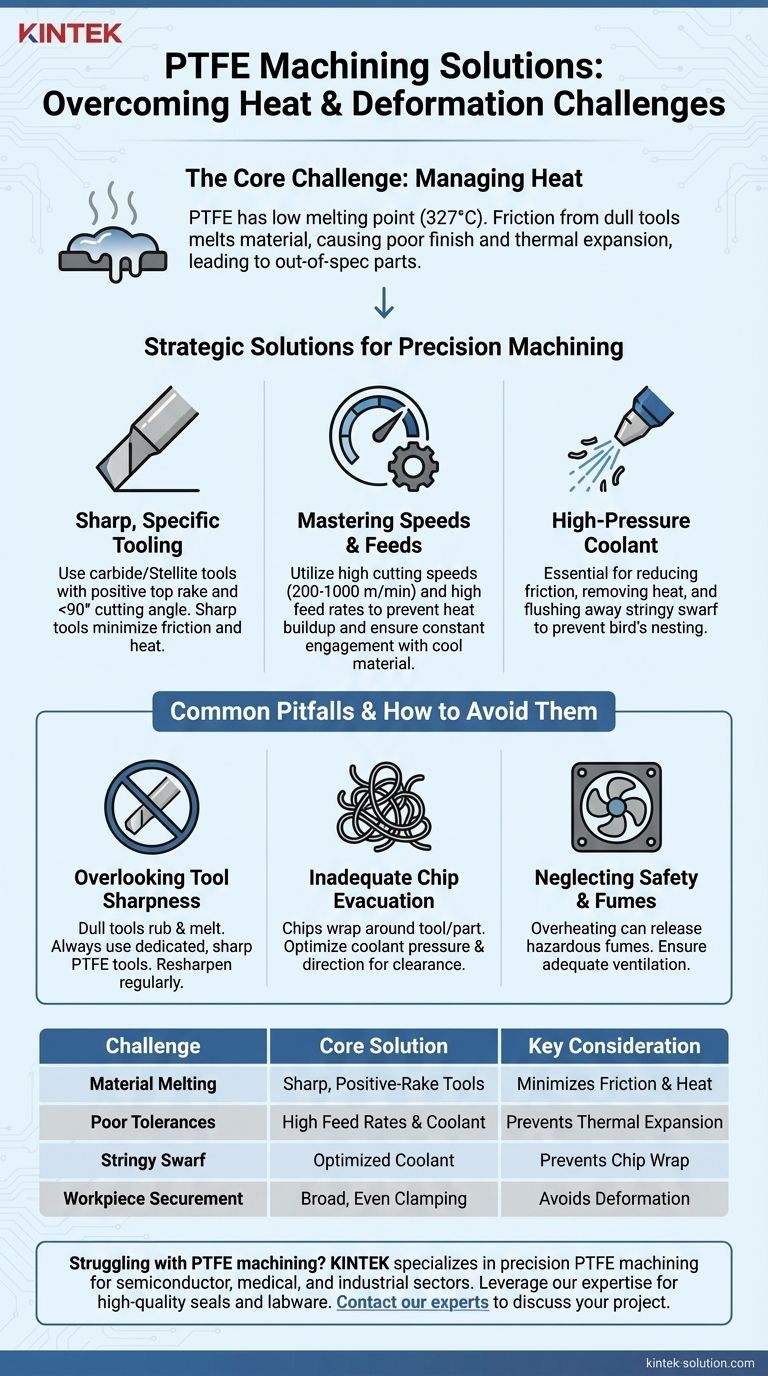

The Core Challenge: Managing Heat and Deformation

Understanding why PTFE is difficult to machine is the first step toward mastering it. Its properties are deceptive; what makes it useful in applications (low friction, chemical inertness) makes it a unique challenge on the mill or lathe.

Why PTFE Melts, Not Cuts

PTFE has a very low melting temperature for a machining process (around 327°C / 621°F). The friction from a cutting tool, especially a dull one, can easily generate enough heat to melt the material instead of shearing it cleanly.

This results in a poor surface finish, material gumming up on the tool, and a loss of dimensional accuracy.

The Problem of Thermal Expansion

As a poor thermal conductor, PTFE does not dissipate heat quickly. Any heat generated by cutting remains highly localized, causing the material to expand significantly.

This localized expansion can ruin tolerances. A part that is perfectly to spec while being cut may become out of spec once it cools to ambient temperature.

Controlling Stringy Swarf

PTFE produces long, continuous, and stringy chips (swarf) during machining. This swarf can easily wrap around the cutting tool or the part itself.

This "bird's nesting" can damage the surface finish, break delicate tools, and become a significant operational nuisance that requires constant monitoring.

Strategic Solutions for Precision Machining

A successful approach to machining PTFE focuses on mitigating the core challenges of heat, deformation, and chip control through specific tooling, parameters, and techniques.

Tool Selection and Geometry are Non-Negotiable

The single most important factor is the cutting tool itself. A sharp tool cuts cleanly with minimal friction and heat.

Use carbide-tipped or Stellite-tipped tools known for holding a sharp edge. The tool should have a positive top rake (between 0 and 15 degrees) and a cutting angle less than 90 degrees. This geometry reduces cutting forces and helps peel the material away smoothly.

Mastering Speeds and Feeds

Controlling cutting parameters is critical for managing heat. The goal is to cut the material and move on before heat has time to build up.

Use high cutting speeds (between 200 to 1000 m/min) and high feed rates. A high feed rate ensures the tool is constantly engaging fresh, cool material, preventing it from dwelling in one spot and generating excessive frictional heat.

The Role of High-Pressure Coolant

Coolant is not optional for most PTFE operations. It serves three critical functions.

First, it reduces friction between the tool and the workpiece. Second, it actively removes heat from the cutting zone. Third, high-pressure coolant jets are highly effective at clearing away stringy swarf before it can wrap around the tool.

Securing the Workpiece

PTFE's slick, low-friction surface makes it difficult to hold securely without causing damage.

Use fixtures that provide broad, even clamping pressure to avoid deforming the soft material. Over-tightening a vise can easily compress the part, leading to inaccurate final dimensions once the pressure is released.

Common Pitfalls and How to Avoid Them

Even with the right strategy, several common mistakes can compromise the quality of a machined PTFE part. Awareness of these pitfalls is key to consistent success.

Overlooking Tool Sharpness

A tool that is even slightly dull will immediately begin to rub and push the material rather than shear it. This is the primary cause of melting and poor surface finish.

Always dedicate specific, sharp tools for PTFE and never use them on other materials. Inspect and resharpen them regularly.

Inadequate Chip Evacuation

Ignoring swarf management will inevitably lead to a failed part. If chips begin to wrap around the tool, they will mar the surface finish and can cause the tool to break.

Ensure your coolant pressure and direction are optimized to force chips away from the cutting area immediately.

Neglecting Safety and Fume Extraction

If PTFE is overheated, it can emit hazardous fumes. While proper machining technique should prevent this, it remains a critical safety consideration.

Ensure adequate ventilation in the work area as a standard precaution when machining any polymer, especially fluoropolymers like PTFE.

Making the Right Choice for Your Goal

Your specific objective will determine which aspect of the machining strategy to prioritize.

- If your primary focus is rapid material removal (roughing): Prioritize high feed rates combined with a sharp carbide tool and aggressive high-pressure coolant to clear material and heat as quickly as possible.

- If your primary focus is achieving tight tolerances and a fine finish: Emphasize an exceptionally sharp, positive-rake tool with a shallow depth of cut and ensure coolant is perfectly aimed to prevent any swarf from touching the finished surface.

- If your primary focus is operational safety: Ensure robust ventilation is in place to manage fumes from any potential overheating, regardless of the cutting parameters used.

By adopting a mindset focused on heat management rather than material hardness, you can turn this challenging polymer into a predictable and reliable material to machine.

Summary Table:

| Challenge | Core Solution | Key Consideration |

|---|---|---|

| Material Melting | Sharp, positive-rake carbide tools | Minimizes friction and heat generation |

| Poor Tolerances | High feed rates & high-pressure coolant | Rapidly removes heat to prevent thermal expansion |

| Stringy Swarf | Optimized coolant direction and pressure | Prevents chips from wrapping around the tool/part |

| Workpiece Securement | Broad, even clamping pressure | Avoids deforming the soft material |

Struggling to machine PTFE components that meet your exact specifications? KINTEK specializes in precision PTFE machining for the semiconductor, medical, laboratory, and industrial sectors. We leverage expert knowledge of tool geometry, heat management, and chip control to deliver high-quality seals, liners, and custom labware—from prototypes to high-volume production.

Contact our machining experts today to discuss your project and ensure flawless results.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials