To improve the surface finish of machined PTFE, the most effective post-processing steps are mechanical polishing and buffing. These methods use soft pads, such as felt, in combination with ultra-fine abrasive compounds or diamond paste to gently refine the surface and remove tooling marks. The key to success is careful management of friction and heat to avoid damaging the material.

The core challenge with PTFE is its softness and extreme sensitivity to heat. Therefore, improving its surface finish is less about aggressive material removal and more about a controlled, low-temperature abrasive process that refines the surface without melting or deforming it.

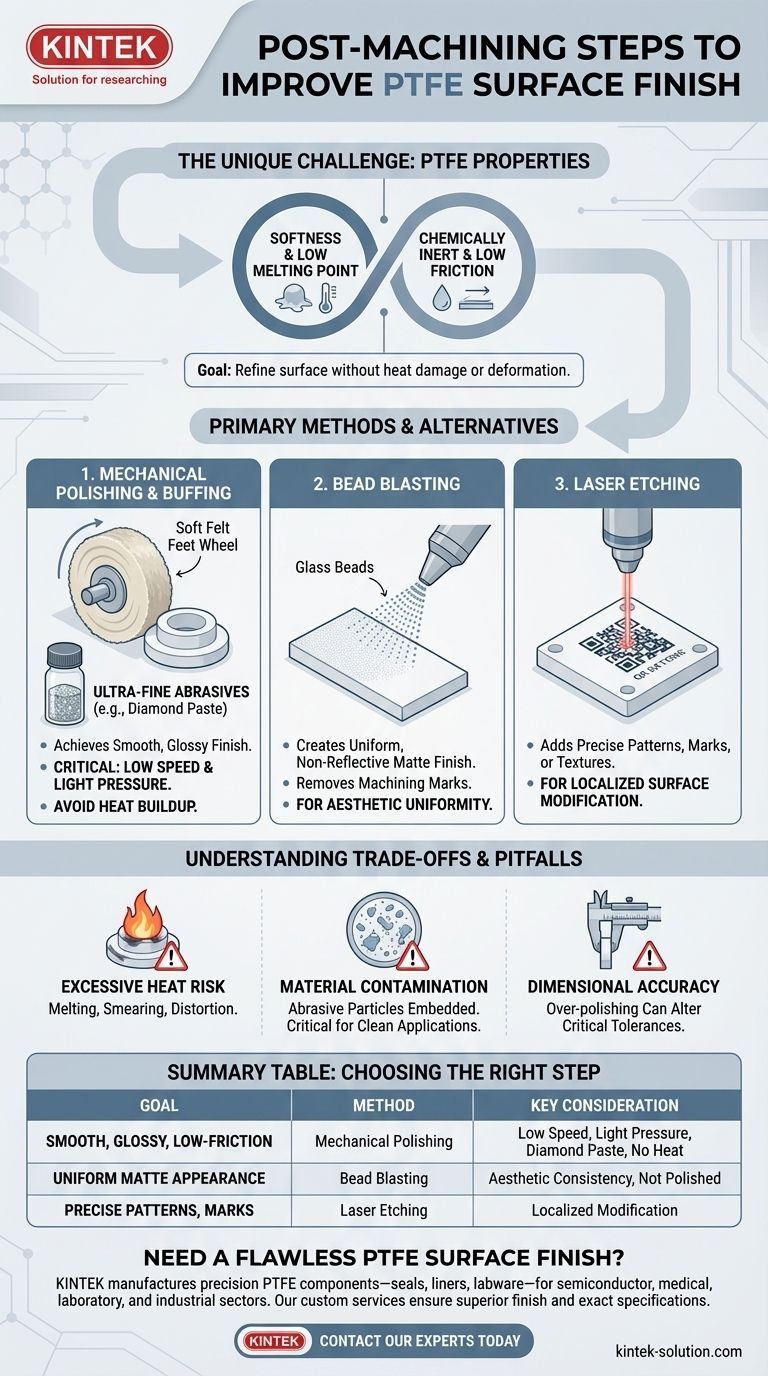

The Unique Challenge of Finishing PTFE

Before applying any technique, it's critical to understand why PTFE (Polytetrafluoroethylene) requires a specialized approach. Its properties make it fundamentally different from metals or harder plastics.

Understanding PTFE's Properties

PTFE is exceptionally soft and has a very low melting point compared to other engineering materials. It is also chemically inert and has an extremely low coefficient of friction.

This combination means that aggressive techniques easily generate enough localized heat to cause smearing, melting, or dimensional changes. Its "slipperiness" can also make it difficult for some abrasives to gain purchase.

The Goal of Post-Machining

The primary goal is to carefully remove the microscopic peaks and valleys left by initial machining operations like CNC milling or turning. The aim is a smoother, more uniform surface without introducing new defects.

Primary Methods for Improving Surface Smoothness

The most reliable methods for achieving a polished finish on PTFE are based on gentle mechanical abrasion.

Mechanical Polishing & Buffing

This is the most common and effective technique for achieving a smooth, often glossy, finish. It involves using a rotating soft wheel or pad, typically made of felt.

The process relies on very light pressure and controlled speeds to avoid heat buildup, which is the single most significant risk factor.

The Role of Fine Abrasives

To effectively smooth the surface, a polishing medium is required. Ultra-fine abrasive compounds or diamond paste are the standards for PTFE.

Diamond particles are hard enough to cleanly shear the soft PTFE material without generating excessive friction and heat, leading to a superior finish.

Alternative Surface Refinement Techniques

While polishing is used for smoothness, other methods can refine a surface for different functional or aesthetic goals. These do not necessarily result in a lower surface roughness (Ra).

Bead Blasting for a Uniform Matte Finish

Bead blasting propels fine media (like glass beads) at the surface. This does not create a polished, reflective finish.

Instead, it removes machining marks and imparts a consistent, non-reflective matte texture. This is often used for aesthetic uniformity rather than for achieving maximum smoothness.

Laser Etching for Targeted Texturing

Laser etching is a highly specialized process used to create precise patterns, marks, or localized textures on the PTFE surface.

This is not a method for overall smoothing but rather a way to add specific features to a targeted area of the part after the primary machining is complete.

Understanding the Trade-offs and Pitfalls

Successfully finishing PTFE requires awareness of what can go wrong. The material's softness and thermal sensitivity are at the heart of every potential issue.

The Danger of Excessive Heat

This is the most critical pitfall. Too much speed or pressure during polishing will instantly melt the surface, creating a smeared, distorted finish that is often worse than the original machined surface.

The Risk of Material Contamination

Because PTFE is so soft, particles from the abrasive compound or polishing pad can become embedded in the surface. This is a major concern for medical, semiconductor, or food-grade applications. Meticulous cleaning is essential.

Maintaining Dimensional Accuracy

Any post-machining process removes material. Over-polishing or aggressive blasting can alter the part's final dimensions, potentially pushing critical features out of tolerance. The process must be gentle and highly controlled.

Making the Right Choice for Your Goal

The best post-machining step depends entirely on your desired outcome.

- If your primary focus is achieving the smoothest, lowest-friction surface: Use mechanical polishing with a felt pad and diamond paste, maintaining low speeds and light pressure.

- If your primary focus is creating a uniform, non-reflective matte appearance: A controlled bead blasting process is the most effective choice.

- If your primary focus is adding specific textures, part numbers, or patterns: Laser etching offers precise control for localized surface modification.

Ultimately, mastering PTFE finishing comes from respecting the material's limitations and applying the correct technique with careful control.

Summary Table:

| Post-Machining Step | Primary Goal | Key Consideration |

|---|---|---|

| Mechanical Polishing | Achieve a smooth, glossy, low-friction surface | Use low speed, light pressure, and diamond paste to avoid heat buildup |

| Bead Blasting | Create a uniform, non-reflective matte appearance | Provides aesthetic uniformity but not a polished finish |

| Laser Etching | Add precise patterns, marks, or textures | Used for localized modification, not overall smoothing |

Need a Flawless PTFE Surface Finish?

PTFE's unique properties demand specialized post-machining expertise to avoid heat damage, contamination, and dimensional inaccuracy. At KINTEK, we manufacture precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services, from prototypes to high-volume orders, ensure your parts meet exact specifications with a superior surface finish.

Let us handle the details. Contact our experts today to discuss your PTFE finishing requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Three Neck Flasks for Advanced Chemical Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments